We choose the best polypropylene pipes. Plumbing from polypropylene own hands

Many of us have heard enough about such material as polypropylene, however, not everyone can say what he is. This is a high-tech product of the new generation, which has unique properties, which provided the use of this material in the manufacture of pipes for various purposes.

It is not by chance that for many years now polypropylene pipes are in demand among consumers not only in our country, but also abroad.

The main reason is the combination of such properties as low cost, excellent quality and no installation problems. These products are distinguished by a wide variety of species, which has provided them with wide distribution in various fields.

Today, such structures are used in the construction of heating and water supply systems for residential buildings, and they also serve as a highway, through which aggressive industrial substances are delivered.

Many consumers in selecting products necessarily pay attention to such a factor as price. For this reason, it makes sense to get acquainted with the fact, how much are polypropylene pipes, which today offers the market.

Polypropylene pipes: advantages and disadvantages

The manufacturing technology used is one of the key factors that determines the technical parameters of polypropylene pipes. First of all, this refers to their ability to withstand high temperatures and operating pressures. Not the least role is played by the diameter and thickness of the inner walls, which determines in which areas these or other modifications of polypropylene products will be used. Based on the above criteria, the following types of polypropylene pipes can be distinguished:

Also it is necessary to dwell on the advantages of polypropylene products:

- high service life;

- non-adherence to corrosion, as well as the formation of any deposits on the inner surface;

- lightness, which makes it easy to install;

- immunity to critical temperatures of any range. They also suffer sharp fluctuations;

- affordable price;

- no harm to health during operation;

- ability to effectively withstand the negative effects of chemicals and alkalis.

Application of polypropylene pipes in heating and sewage systems

It should be reiterated that when choosing polypropylene pipes, first of all it is necessary pay attention to the purpose of their use. For this reason, before the final decision is made, the information in the technical documentation should be carefully read.

It should be reiterated that when choosing polypropylene pipes, first of all it is necessary pay attention to the purpose of their use. For this reason, before the final decision is made, the information in the technical documentation should be carefully read.

On the basis of the information obtained, it is necessary to compare with a specific heating, water supply, ventilation and sewage system, considering as the main parameter the operating conditions of polypropylene pipes for water supply.

When performing work on the installation of internal and external sewage systems, most often the choice is stopped on structures that are able to effectively withstand aggressive environments, mechanical loads and thermal effects. To make polypropylene constructions for water supply of higher strength characteristics resort to such a common operation as reinforcement based on aluminum foil and steel rims.

The pipes used for the sewerage system are characterized by a wide coverage of the diameter, which is in the range from 50 to 600 mm. This makes it possible to guarantee good flow capacity. Application in the design of the rubber ring simplifies the installation work and provides a high level of tightness.

When starting the installation of heating systems, it is necessary to take into account a number of requirements that polypropylene pipes must satisfy. Among them, one of the key ones is the temperature regime, which has a transported liquid. This parameter should become decisive when choosing pipes for the construction of sewerage and heating systems, for which the presence of reinforced layers on the basis of aluminum foil, fiberglass and composite material is mandatory.

Cost of different modifications of polypropylene pipes for water supply

When choosing a design made of polypropylene, it should be noted that the price of these products is affected by several factors:

- variant of execution;

- company manufacturer.

The latter factor influences the fact that different companies create polypropylene pipes for water supply with the use of different modifications of polypropylene. At the same time, we should not forget about the proprietary patented technology, which in any case will affect the final quality and service life of the product.

Among the presented options, the largest representation in the domestic market is polypropylene pipes for cold water supply, produced by German manufacturers Banninger Reiskirchen, Wefatherm and Ecoplastik. Their products are of high quality and, accordingly, the same price.

Among the presented options, the largest representation in the domestic market is polypropylene pipes for cold water supply, produced by German manufacturers Banninger Reiskirchen, Wefatherm and Ecoplastik. Their products are of high quality and, accordingly, the same price.

The lowest level of quality is inherent in products offered by Russian and Chinese enterprises. For this reason, the best solution will be pipes that have an optimal price-quality ratio. This requirement is fully met by the designs manufactured by Italian and Turkish companies.

The difference in price is largely due not only to the specific type of pipes, but also to their purpose:

Comparison of the cost of polypropylene with pipes from other materials

Although polypropylene is a fairly popular material used for the production of pipes used for heating, water supply, conditioning and sewage systems, it still has alternatives. If we talk about the most popular analogs, then the following constructions should be included in this list:

Copper pipes

These products will never lose the status of a reference solution, on the basis of which internal heating and water supply systems can be created. The only obstacle, because of which such pipes have not received proper distribution, is their high price. A sign of the quality of copper pipes is presence of marking EN 1057, which is characterized by the presence of pure copper without impurities in an amount of 99.3%. This product is offered at a price of 201 rubles. per meter of pipe size 15 x1.0. The most expensive option - a pipe size 35 x1.0, which the manufacturer set the price of 760 rubles. per meter.

PEX-A PEX-A pipes

These designs are distinguished by the presence of certain advantages, among which the main one should be called thermal memory, which manifests itself under any temperature regime. This product is 95% cope with the impact the maximum working pressure of 10 bar. Pipes with dimensions of 16 x 2, 0 are offered at a price of 75 p. per meter, and for products with dimensions of 110 x 10,0 the manufacturer set the price of 2550 rubles. per meter.

These designs are distinguished by the presence of certain advantages, among which the main one should be called thermal memory, which manifests itself under any temperature regime. This product is 95% cope with the impact the maximum working pressure of 10 bar. Pipes with dimensions of 16 x 2, 0 are offered at a price of 75 p. per meter, and for products with dimensions of 110 x 10,0 the manufacturer set the price of 2550 rubles. per meter.

Metal-Plastic Pipes

These products have become widespread in the construction of cold and hot heating systems, and besides this, radiator heating systems. Among the main advantages are oxygen impermeability, non-adherence to corrosion. Pipes are offered at a price of 79 to 5320 rubles. per meter.

Conclusion

Polypropylene water supply has been successfully used for many years in many branches of the national economy. At the same time, many consumers still pay attention to the price when choosing them. And it can depend on several parameters, from which it is necessary to make a decision in favor of a particular type. Therefore, only on the condition that the selected pipe will fully meet the requirements of the buyer, you can expect that he will be completely satisfied with his decision.

Polypropylene pipes for water supply are an excellent alternative not only to metal pipes, but also to products from other types of polymers. Comparing them by individual characteristics, one can easily come to the conclusion about their universality and suitability for use in different areas, including for cold and hot water supply.

In addition to polypropylene, polyvinyl chloride and high-pressure polyethylene are used for the production of water pipes, but their only advantage over polypropylene is a lower price, otherwise they lose by some parameters in comparison. So, for example, the working temperature of polyethylene pipes at a level of 40 degrees automatically makes them unsuitable for hot water supply, for the same reason there are no PVC pipes.

Properties of polypropylene pipes

Such a product as a polypropylene pipe is one of the best options for application in this field due to a set of its qualities, which include the properties described below:

- Durability. The projected lifetime of pipes from this material is about half a century, during this period the water supply system will more likely require modernization than repair or replacement of pipes. Today, science and industry offer all new solutions in construction, so it is possible that the availability of more modern and effective solutions will require the reconstruction of the water pipe much earlier than the pipes will become unusable.

- Reliability. Comparing polypropylene with other materials, the increased characteristics of its strength immediately become apparent. It withstands high pressure in the system. In order to guarantee the absence of leaks, for different sites it is necessary to purchase a suitable type of pipe. The industry manufactures products designed for a pressure level of 10 to 20 atmospheres, in addition, products from reinforced polypropylene can be purchased for use in the most critical locations.

In the system, you can use different brands of pipes, so as not to overpay for excessive and unnecessary strength in some places.

- Resistance to different types of impacts. High positions are occupied by polypropylene pipes for water supply and by the degree of resistance to various aggressive factors. They are not afraid of temperature changes, the impact of aggressive reagents, as well as mechanical damage. Even when the water pipe freezes, the pipes not only do not lose their integrity, but they do not even deform after thawing.

- Ease of installation. In order to connect pipes from this material to each other, it does not require high qualification and special knowledge, quite basic skills and exact follow instructions. Fittings for connecting polypropylene pipes are quite affordable, and installation with their help is not difficult, only an apparatus for heating and welding is required.

Types of polypropylene pipes

The industry produces polypropylene pipes of several types, each of which has its own specific application:

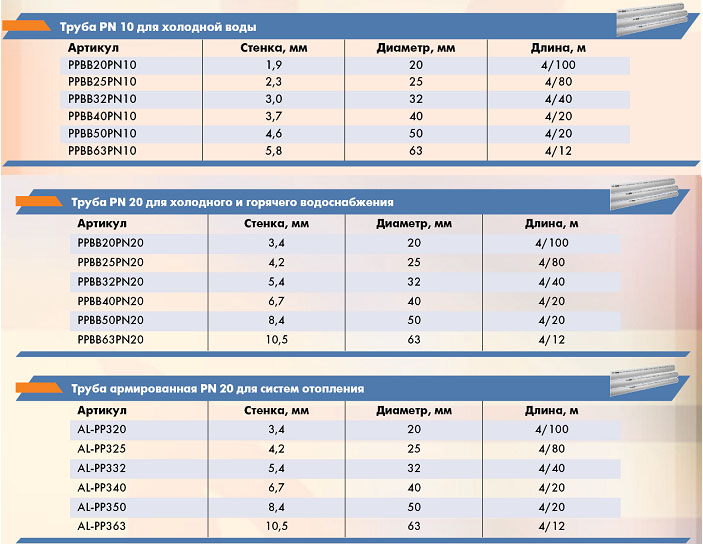

- PN10 - under this design, polypropylene pipes for cold water are concealed. They have the lowest cost of all, as the temperature rises they can change their sizes, and this property must be taken into account during installation.

- PN20 - this kind includes polypropylene pipes for hot water, however, they can also be used for cold water supply. Like the previous view, they are also capable of linear expansion when heated, which should be compensated for by installing sliding supports and various special devices.

- Reinforced pipes. They are designed for a significant temperature load and are used mainly in heating systems.

The PP pipes are different in terms of size and size, including the wall thickness and pipe diameter. The choice of diameter depends not only on the place where the pipe will be laid, but also on the diameter of the soldering iron that will be used for installation.

Plumbing installation

Stages of installation

Laying of water pipes from polypropylene pipes is carried out after all calculations have been made and materials and equipment for installation of the system are purchased. The water pipe can be laid open and closed. In the first case, the work is less time-consuming and faster, but the second option gives a more aesthetic appearance and a saving of useful space.

In general, installation of a water pipe made of polypropylene pipes is carried out as follows:

- Dismantling of old pipes. If you do not repair, and construction, the route for laying pipes is marked, fixing points, ramifications and other key points are noted.

- If the water pipe is laid again, the walls are shtrobyatsya, holes are made in the partitions, fasteners are installed. Shtroby necessary for closed laying of the pipeline, fasteners - for open.

- According to the design or marking, pieces of polypropylene pipes of the required length are cut off, the fitting elements are mounted on the ends. If polypropylene pipes are to be connected to metal pipes, for example, when connected to a common network, the connection couplings are installed at the ends of the segments that will be in these places.

- Welding of polypropylene pipes according to a pre-compiled scheme.

- A shut-off valve is installed.

- The assembled pipeline is put in place if a closed method is chosen, then plastering work is carried out.

How is polypropylene pipes welded?

Separate attention deserves welding polypropylene water pipes. In order to proceed to this stage, the pipes must be bent in those places where it is planned by the project.

To obtain the desired configuration, the pipe is heated with a construction hair dryer in the right place, after which it becomes plastic and bends. It is also possible to use ready-made corner fittings, then there is no need to bend the pipes.

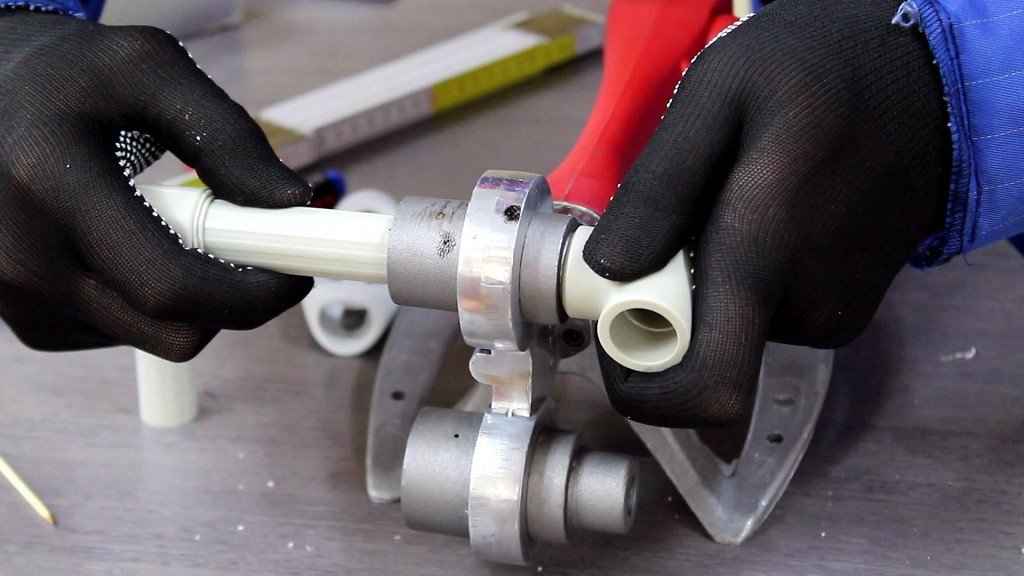

In order to connect PP pipes for water supply, it is necessary to have a special soldering iron available. The diameter of its attachments can be different, and before acquiring pipes, care should be taken to ensure that their dimensions match.

- The soldering iron is checked, the nozzle must be pre-cleaned of polymer residues. Then you can turn it on in the network, setting the temperature at 260 degrees.

- A fragment of the pipeline, pre-cut in the required length, is put on the heated nozzle of the soldering iron, a similar operation is performed with the fitting that will be used for the connection.

- The heated parts are connected properly, inserting the pipe into the fitting, and then left in a fixed position for 2-3 minutes. It is impossible to touch and move the pipe during this period, since it is impossible to re-produce this connection without cutting the pipes and using a new fitting.

The technology of connecting polypropylene pipes is simple and accessible due to the fact that it does not require special knowledge, and the cost of the soldering iron used for this process is relatively low relative to the apparatus used to connect pipes from other materials.

The popularity of polypropylene pipes is justified by their high quality, affordable price and simple installation. To date, polypropylene is the most common and safe material not only for external pipelines, but also for internal networks. They are successfully used in the construction of any plumbing and heating systems.

Varieties of polypropylene pipes

The main difference between pipes made of polypropylene is the reaction to high temperatures. On this depends and their destination. Manufacturers produce pipes for:- cold water;

- hot water;

- sewage;

- heating;

- ventilation.

Polypropylene pipes are manufactured reinforced and unreinforced. They also differ in their ability to withstand working pressure:

- 1 MPa (PN10 grade) - it is used for cold water (up to + 20С), air conditioning and ventilation systems, as well as for a "warm floor" device (up to + 45С);

- 1,6 MPa (PN16 grade) - is extremely rare, installed on pipelines of cold and hot water (up to + 60С), as well as for underfloor heating;

- 2 MPa (PN20 grade) - suitable for hot (up to + 80 ° C) and cold water;

- 2,5 MPa (PN25 grade) - specially reinforced pipes intended for heating (not more than + 95С), hot water, as well as process pipelines.

Each type of polypropylene pipes has its dimensions:

- PN10 - outer diameter from 20 to 110 mm with a wall thickness of 1.9-10 mm;

- PN16 - outer diameter from 16 to 110 mm with a wall thickness of 2.3-15.1 mm;

- PN20 - outer diameter from 16 to 110 mm with a wall thickness of 16-18.4 mm;

- PN25 - outer diameter from 21.2 to 77.9 mm with a wall thickness of 4-13.3 mm.

The technical characteristics of pipes made of polypropylene directly depend on the plastic, from which they are made:

- PPH is a homopolymer of propylene;

- RRB - block copolymer, or copolymer of polypropylene, ethylene;

- PPRS (abbreviated as PPR) is a random copolymer, or a static copolymer with ethylene.

As a rule, the third type of polymer is used for the production of pipes, since it has improved elasticity properties, as well as viscosity and high temperature resistance. PPR refers to heat-resistant plastics, has a low weight in combination with high strength, is resistant to the action of virtually any acid  and alkaline solutions. The temperature of the transported liquid can be in the range from -10 to +90 degrees. PPR pipes withstand a short-term exposure to temperatures up to +110 degrees. Frozen water in them does not lead to the destruction of the pipeline.

and alkaline solutions. The temperature of the transported liquid can be in the range from -10 to +90 degrees. PPR pipes withstand a short-term exposure to temperatures up to +110 degrees. Frozen water in them does not lead to the destruction of the pipeline.

Polypropylene pipes are produced, usually white, black, green, red, blue, red and gray, which does not label the product in any way. The only difference is that the black color protects the pipes from direct exposure to ultraviolet light.

Peculiarities of sewer pipes

Polypropylene firing pipes are widely used for non-pressure sewage systems:

- internal;

- external;

- storm water.

For intra-house networks, pipes are produced with a diameter of up to 110 mm length from 300 mm to 2 m. For external sewerage, corrugated pipes are made by cuts of five meters and a diameter of 150 mm more, and products with a diameter of 600 mm can have a length of up to 10 meters. Gofra makes the pipeline more resistant to any ground subsidence and less prone to external loads.

For intra-house networks, pipes are produced with a diameter of up to 110 mm length from 300 mm to 2 m. For external sewerage, corrugated pipes are made by cuts of five meters and a diameter of 150 mm more, and products with a diameter of 600 mm can have a length of up to 10 meters. Gofra makes the pipeline more resistant to any ground subsidence and less prone to external loads.

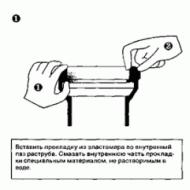

Installation of sewer pipes from polypropylene is quite simple. The end of one product is inserted into the socket of another, and the tightness is provided by means of a sealing rubber ring.

Polypropylene pipes for ventilation

The main function of the pipes in the ventilation system is to ensure the outflow and supply of air. Therefore, special strength is not required here, and such an advantage, as a small weight, is welcomed, since very often they are mounted not on the capital walls, but on partitions or in general are hidden in the construction of suspended ceilings.

Ventilation pipes can have an oval, rectangular, round or complex shape. Their size depends on the size and purpose of the room. In residential buildings, ventilation is usually arranged with a diameter of 100 or 125 mm. The pipes are joined by the socket method without the need for sealing.

Reinforced polypropylene

Reinforced polypropylene

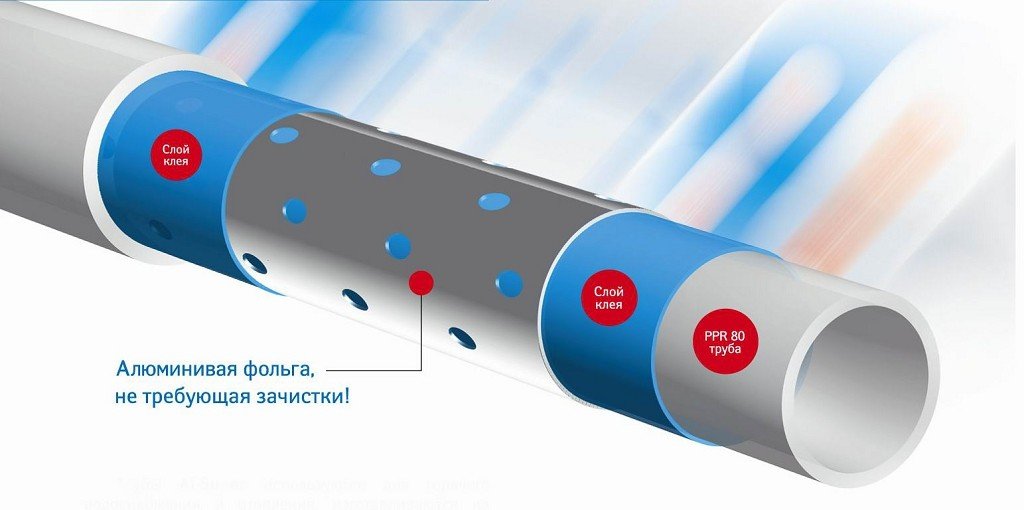

For heating systems, reinforced PN25 pipes should be used. Manufacturers use several methods of reinforcement:

- wrapping the pipe from the outside with a solid or perforated layer of aluminum foil;

- the device of the inner aluminum interlayer is closer to the outer edge, the perforated foil allowing the layers to be joined without using an adhesive;

- fiberglass;

- with an inner layer of a composite mixture consisting of polypropylene and glass or fiberglass.

The use of aluminum foil significantly reduces the coefficient of thermal expansion, but there are certain difficulties in the jointing of pipes and their connection with fittings. In this case, the ends of the pipes must be cleaned, especially with the first method of reinforcement, for which a special welding nozzle or face is used.

Reinforcement with fiberglass allows welding pipes without stripping their ends, which undoubtedly simplifies the installation work. Composite adds strength to products, and the index of linear expansion practically reduces to zero. Such technologies make it possible to obtain products whose strength is twice as high as that of steel analogues.

Pros and cons of polypropylene pipes

The advantages of polypropylene pipes are many. The main of them is, of course, a long service life with competent installation and operation. In cold water supply systems, this period can be guaranteed to be 100 years, and for hot water systems - 50 years. You can identify a few more undeniable advantages:

- resistance to sudden changes in pressure and temperature;

- excellent sound absorption;

- low thermal conductivity;

- no corrosion and no deposits;

- quick and easy installation;

- a small mass that allows you to reduce labor costs;

- low cost;

- minimum maintenance costs;

- endurance at negative temperatures;

- resistance to chemical environments.

Disadvantages polypropylene pipes have almost no. The only drawback is a high index of linear expansion, which is responsible for changing their length when exposed to hot water. However, the correct use of pipe variants for certain coolant temperatures, as well as the installation of sliding supports and compensators, will help to reduce problems.

What are fittings used for?

The arrangement of any pipeline assumes different branches, connections and turns. The possibility of their device is provided by fittings. They are divided into several types, differing in the way of fastening, materials and purpose. By the method of connection, they can be:

- flanged;

- crimp;

- threaded;

- welded.

Fittings made of polypropylene refer to the welded and threaded type of connection. On their surface there are special incisions, helping to determine the position of the fitting during welding. They have the same advantages as polypropylene pipes, and it is impossible to do without them when installing water and heating systems.

Marking of fittings corresponds to the marking of pipes - PN10, PN16, PN20 and PN25. Manufacturers produce:

- tees;

- bends;

- couplings;

- sliding and fixed supports;

- plugs;

- knees (turns);

- flanges;

- contours;

- ball Valves;

- valves and much more.

There are also electric welded fittings in the construction, in which the electric heaters are laid. They are used in the case when butt welding does not justify itself. Typically, this happens when repairing damaged areas, in crowded or difficult weather conditions.

Polypropylene fittings are joined together not only by polypropylene pipes. For connection with pipes made of other materials, various adapters, couplings and drifts are produced. Fittings with chrome or brass inserts make it easy to make connections to absolutely any sanitary fittings. It should be noted that fittings and pipes must be manufactured by one manufacturer, otherwise it is unlikely that anyone will be able to guarantee the quality of the connections.

Installation of pipelines from polypropylene

Polypropylene pipes are connected by means of thermal welding, or soldering. To do this, use a special soldering iron. To seam turned out qualitative, it is necessary to train on inexpensive pipes and couplings or use for this purpose any cuttings. The fact that the process of adhesion occurs quickly enough and if you do not have time to weld the elements firmly fixed in the correct position for a few seconds, then turn the fitting or pipe without damage to the seam is no longer possible.

Polypropylene pipes are connected by means of thermal welding, or soldering. To do this, use a special soldering iron. To seam turned out qualitative, it is necessary to train on inexpensive pipes and couplings or use for this purpose any cuttings. The fact that the process of adhesion occurs quickly enough and if you do not have time to weld the elements firmly fixed in the correct position for a few seconds, then turn the fitting or pipe without damage to the seam is no longer possible.

Currently, three types of welding are performed, resulting in a uniform weld:

- polyfuznuju, or муфтовую, - for pipes in diameter to 63 mm;

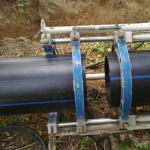

- butt joint, or flanged, - for pipes with a diameter of more than 63 cm;

- with the use of electrofitting.

Any welding allows to obtain an all-in-one joint, made by heating the bonded sections to the stage of reflow of polypropylene. In the first case, an apparatus for socket fusion will come to the rescue, and in the second case a device with a clamping hydraulic mechanism.

Any welding allows to obtain an all-in-one joint, made by heating the bonded sections to the stage of reflow of polypropylene. In the first case, an apparatus for socket fusion will come to the rescue, and in the second case a device with a clamping hydraulic mechanism.

Soldering irons are equipped with nozzles of various diameters with Teflon coating, which are used to reflow the inner surface of the socket part or coupling and the outer surface of the pipe end.

Prior to welding, polypropylene pipes with an aluminum foil outer location must be cleaned to fit into the coupling or other fitting. For other pipes, this is not necessary. The parts to be soldered must be thoroughly cleaned of dust, and then degreased. After that, you can start installing the pipeline.

- The pipe is cut at a right angle with special scissors or a hacksaw for metal.

- A suitable nozzle is installed on the soldering iron and the device is turned on to heat up to the required temperature of 250-270 degrees. It should be noted that the warm-up time is 15-20 minutes.

- The socket of the fitting on one side of the apparatus is put on the mandrel, and on the other - the end of the pipe is inserted into the sleeve to the mark of the depth of welding.

- After the heating of both elements, they are removed from the nozzle and connected confidently with each other, observing mutual alignment. The necessary heating time depends on the diameter of the pipe.

- The cooling time of the weld seam is a few seconds, during which a turn or bend is not allowed. Incorrect connection is not subject to correction, it is simply cut out.

It is important to know that if the underheat is not warm enough, the joint will be unreliable, and when overheating, the shape of the product will be lost, and the seam will become deformed.

How to properly weld polypropylene pipes, you can see on the video:

For connection with metal or metal-plastic pipes, fittings with threaded inserts on one side are used, additionally applying various gaskets.

It is worth noting that polypropylene pipes can change their size when heated, so when using them in a hot water supply system, the installation is performed using sliding supports and various compensators - round, G-shaped and U-shaped.

Conclusion

Polypropylene pipes are well received by consumers, thanks to their exceptional characteristics and qualities. Thinking about replacing internal water and sewer pipes in your home or apartment, you should pay attention to products made of polypropylene. With a competent choice and proper installation, they will not create problems for a long time.

5 October 2015  Alexey

Alexey

The use of metal pipelines in the arrangement of sewage and heating systems, as well as water supply is gradually becoming a thing of the past.

Worthy replacement of it became products from materials of polymer origin. The best polypropylene pipes are not only inferior to analogues of metal in their qualities, but also surpass them in many respects.

That allows you to mount pipelines that can withstand high temperatures and significant pressure. The material is strong and elastic, even when the product freezes, remain unscathed, as their walls expand together with frozen water, and after thawing they acquire the original state.

Features and specifications

At present, a large number of elements and constructions of pipeline systems made of polymers are represented in the market of sanitary equipment. A significant segment is occupied by products made of polypropylene. There are products, both Russian manufacturers, and foreign.

We look at video, types and their advantages:

Therefore, the main question today is which of all this variety to choose polypropylene pipes, so that they meet the requirements for them in each specific case. To do this, you first need to have an idea of what these products represent and what advantages or disadvantages they have.

The main positive properties can be called the following:

- Resistance to corrosion;

- Long service life;

- Resistance to aggressive substances;

- Reliability;

- Low noise level, no vibration;

- Low coefficient of hydraulic resistance;

- Low heat emission;

- Ease of installation;

- Environmental Safety.

It should be noted that polypropylene pipes and other elements or structures, the choice of which is due to the above features, make it possible to maintain quality indicators of pipeline systems over many years of operation.

Products made of polymers are distinguished by chemical inertness and excellent cross-country ability. Polypropylene practically does not lend itself to tears, which increases the reliability of the use of pipes in the winter. The noise of water passing through them is not audible and does not cause discomfort to others.

Unlike metal pipes, the heat of hot water in polypropylene products is much higher. There is also a high reliability of connections, and a huge selection of fittings makes it possible to wiring any system, no matter how complicated its configuration.

What are the types

Depending on the design, two types are distinguished:

- Single-layer;

- Multilayered.

The first group, in turn, is divided into several types:

- PPH - is made from homopolypropylene and is used in cold water supply, with the arrangement of ventilation and industrial pipelines;

- RRV - made of block copolymer, used in floor heating and for cold water supply;

- PPR-material is a random copolymer of polypropylene, it is possible to use for hot water supply, water heating and in floor heating systems;

- PPs - special polypropylene, which possesses hardly flammable properties.

The second group includes multilayer polypropylene pipes, and in order to know how to choose from them, we advise paying attention to their reinforcement. They are mainly used in heating systems. Their elongation at high temperatures is much less than that of single-layer ones. Armored products can be smooth or perforated.

Selection of pipes for water supply organization

To date, the main area of their application is the supply to water objects. Reinforced pipes are used for hot water supply, and non-reinforced pipes are used for cold water supply. The material from which they are made can withstand a temperature of 90 degrees. Such pipes are well proven in the laying of internal systems.

Watch the video, the selection criteria:

This is also facilitated by their durability, the service life can reach 50 years or more. In addition, even the best polypropylene pipes chosen for domestic water supply are much lower in cost than copper or steel analogues.

Preference is given to them taking into account such important advantages as:

- Low cost;

- Strength and durability;

- Simple installation;

- Reliable tightness of joints;

- The possibility of use in the arrangement of heating and hot water.

Even the best pipes have some disadvantages associated with their installation. The matter is that at installation all connections become all-in-one and in case of an error or poor-quality execution the problem site should be cut out and re-soldered again. It is clear that the main condition for equipping the system from such pipes is the availability of a welding machine.

Overview of popular manufacturers

Plastic gradually displaces metal pipes from water and heating systems. It is not afraid of corrosion, it does not collapse under the influence of aggressive environments, is able to withstand low and high temperatures, is light and has a low cost.

Therefore, it has become very popular on the market. Today the main question that interests consumers: which firm polypropylene pipes are better? Let's try to determine which of the manufacturers the ratio of quality and cost is the most profitable.

Watch a video about Rehau products, opinions of experts:

Judging by the numerous reviews of specialists and homeowners, the leading positions are taken by products from Germany, where they produce the best and highest quality polypropylene pipes to date. The most famous are trademarks:

- Akwatherm;

- Rechau.

The second place is surely occupied by Czech products of such companies as:

- ECOPLASTIC;

- FV-Plast.

The next stage is the pipes produced in Turkey. The most famous brands are Valtek and Kalde.

Polypropylene pipes from China in the list which of them are better in the fourth place. There are two brands:

- Dyzain;

- BLUE OCEAN.

The most budget option is domestic products:

- Politec;

- PRO AQUA;

- Heisskraft;

- Santrade.

In more detail we will get acquainted with what are and how the polypropylene pipes of Russian manufacturers differ.

Watch the video about PRO AQUA products:

Products from the company PRO AQUA are used both in water supply systems for industrial, administrative and residential buildings, and in process pipelines. The permissible temperature in them is +95 degrees. They are not afraid of corrosion, they are resistant to aggressive substances, they are easy to assemble, absolutely harmless. They are able to withstand a high pressure of 79.5 Atm, which significantly increases their service life.

Pipe with the trademark RVC is produced by the Russian company "Plastic" from Orenburg. Manufactured from polypropylene PN 25, they are used in heat and hot water supply systems. They have internal reinforcement of aluminum. One of the shortcomings of the products of this firm is called "dimension walking".

In the suburbs there is a factory on which pipes Heisskraft are manufactured. Their quality is quite high, especially reinforced products, which are manufactured by German technology. It is possible that part of the products are already delivered in ready-made form from Germany.

![]()

Products from Heisskraft

According to numerous positive reviews, the pipes of Highscraft are also characterized by good quality. Consumers are slightly confused by the gray color of the products, which is caused by the addition of technical black in polypropylene. But such an addition in the composition is completely justified, since soot acts as a good stabilizer. This gives the pipes additional strength and elasticity, which should please, rather than upset, consumers.

What are the quality of the polypropylene pipes brand Santrade is still difficult to say, since feedback about them is practically absent. Most quickly this is due to the still not very large popularity of the brand.

What is the length and thickness of the walls to choose Polytek polypropylene pipes depends on the scope of their application. According to installers, their installation does not cause major problems, despite the susceptibility of deformation during compression.

Conclusion

Acquiring products of Russian manufacturers should simultaneously purchase pipes and polypropylene fittings of the same firms, so that the pipeline systems created are homogeneous. Domestic products in many cases have the same technical characteristics as foreign counterparts, but at a lower cost.

Today, polypropylene pipes for hot water have almost entirely supplanted the traditional metal pipes used for water supply, the installation of which is rather laborious. New alternative solutions have many advantages over outdated options for water supply organization.

Advantages of polypropylene pipes

What are the advantages of polypropylene pipes used for hot water supply?

- Durability. The long operational life (for thirty years) of these pipes is associated with their excellent strength and resistance to various negative factors. So, plastic is resistant to corrosion from chemicals and water, unlike metal.

- Due to the smooth inner surface of the walls, water flows more rapidly through the pipes, while no harmful deposits are observed.

- Polypropylene has a low thermal conductivity, which can significantly reduce heat loss in the system.

- Easy installation and easy installation of a hot water supply system is one of the main advantages of plastic pipelines. This makes it possible even for beginners to do the work themselves, saving on the call of specialists.

- These products do not need special care. For example, they retain their original appearance for a long time without needing to tint. Preventive cleaning of communications is much less frequent.

- Polypropylene is an environmentally friendly material that can not emit harmful vapors, despite operating conditions. This is especially important for hot water supply.

- Affordable price is an important criterion for choosing many buyers in favor of plastic pipes.

Advantages over metal communications

Features of plastic pipelines in the system of hot water supply.

- Polypropylene does not lose its hardness at temperatures up to one hundred and forty degrees. Only at higher temperature regimes, its structure can soften, but when the load decreases, the material is completely restored.

Note: the ability to soften is more the merit of the material, which makes it possible to change the shape of the pipeline. Only at a temperature of one hundred and seventy-five degrees of melting the deformation of the material can not be corrected.

- Short-term temperature increase does not affect the performance of polypropylene pipes of any action. But do not allow a prolonged increase in temperature.

PP are the most reliable for the purpose of supplying hot water and have another remarkable property - they are excellent to withstand, which makes it possible to hide communications in the wall. Reinforcement of plastic products is carried out either with the help of fiberglass, or thanks to a layer of aluminum foil.

Installation of hot water supply system from PP pipes.

As already mentioned above, it is even possible for a newcomer to organize a hot water supply system in this business. Detailed instructions will help you in working with polypropylene pipes.

- First of all, it is necessary to mark and pipe the pipes using a special tool that will make even and accurate cuts. Use sandpaper to remove all burrs on the cut.

- When connecting the pipeline to plumbing fixtures, it is necessary to fix it to monolithic walls. Pipes should be located with a small indent from each other.

- To join separate segments it is necessary by means of welding which forms a tight monolithic joint. Docking with the pipeline must be carried out under heat and with effort.

- If it is necessary to connect the PP with another material, for example, metal, use special compression fittings.

- After completing the work, be sure to check the hot water system under the maximum head of water.

Modern technologies allow today to create practical and durable products, although a few decades ago this was not to be considered. Polypropylene pipes will allow to organize an uninterrupted and reliable system of hot water supply without resorting to the services of hired craftsmen. Given all the characteristics of these products, you can safely use them for all regions. The exception is the Far North.