Sanitary wiring adapters. Pvc pipe adapters

When installing the sewage system OSTENDORF (Germany), as well as pipelines of other manufacturers, there are often problems with the connection of elements of different diameters or made of different materials. In this case, as it is impossible by the way will be adapters, rubber, for drainage, providing tightness and reliability of joints.

If the sewage system in a residential or industrial building requires repair or a complete replacement, the master often has to think about how to connect the plastic or cast-iron risers. And then simple does not help. It is necessary to use cuffs, that is special rubber adapters for the sewerage (cuffs), guaranteeing the most dense adherence of materials of different structure.

Installation of adapters for sewage

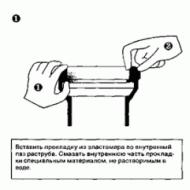

The inner cuffs are placed in the socket of the cast iron pipe, after which plastic elements of the pipeline of various diameters can be attached to it. The external cross-section of the rubber adapters for the sewage system must coincide with the diameter of the socket, and the dimensions of the internal section are determined by the cross section of the plastic pipes. Similar cuffs are used when connecting household appliances, for example, a washing machine, to sewerage by means of a corrugated hose.

External adapters are used for connection to pipes that do not have funnels. Before installing them, align the shear section to eliminate any unevenness of the edge. This will avoid possible clogging of the system. During installation of external rubber adapters for sewage:

- Apply the sealant to the inner surface of the cuff;

- They put it on a cast-iron pipe;

- Waiting for the hardening of silicone sealant.

- Clean the bell from dirt, cement residues, various debris;

- Apply the silicone sealant to the outer surface of the product;

- Insert the adapter into the socket;

- Waiting for the sealant to set.

Installation of rubber adapters, as well as, will ensure the integrity and safety of the entire system in the house. All this you can buy in our online store, we will be happy to help you with the choice!

Method 1: Rubber gasket

If the old cast iron pipe can be easily removed and the inner surface of the cuff (socket) of the remaining pipe made of cast iron is even, an easy way of joining with a special sealant is suitable. In this case, the plastic pipe is inserted into the cast iron pipe to 3, and if possible also to 8 cm. This method allows the connection to proceed quickly and immediately after that to continue the operation of the sewage system. Practice shows that this combination of plastic and cast-iron pipes can function normally for 8 years.

Most often the sewer riser has 2 outlets, the first one having a diameter of 100 for connecting the toilet bowl and the second one 50 for connecting the drainage system, which provides the output of the residential sewage system. In both cases, the connection is made using the same technology. It is necessary:

- clean the bell from rust and dirt;

- apply a sealant to the rubber transition from the outside of the cuff;

- insert the rubber adapter into the cast iron socket;

- insert a new sewer pipe into the cuff.

If the connection has to be made with a pipe that does not have a bell, then a plastic adapter must be used. In this case, proceed as follows:

- part of the cast-iron pipe is cut by the Bulgarian, leveling the edge;

- this part is worn with a rubber adapter;

- miss the edge of the "clad" cast iron pipe sealant;

- on top of the pipe, a plastic adapter (cuff) lubricated with a sealant is also worn.

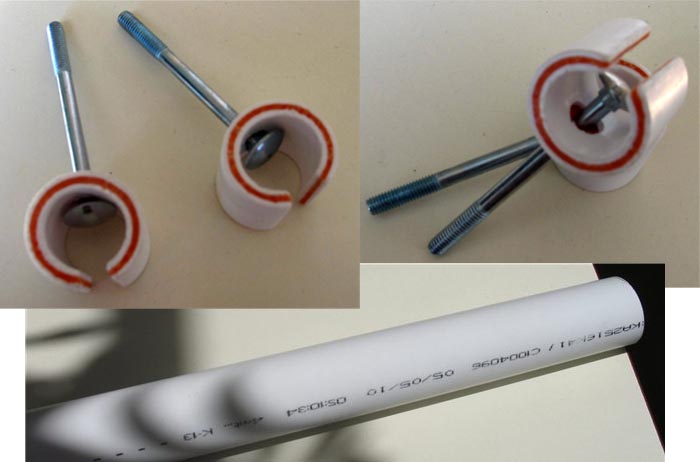

Appearance and scheme of application of the plastic adapter: 1 - plastic bell; 2 - a rubber ring; 3 - plastic adapter; 4 - rubber cuff; 5 - the second rubber ring; 6 - cast-iron pipe without bell.

Cuffs and transitions must have a corresponding pipe size. The connection of cast-iron and plastic pipes according to the technology of making the transition is the same for all diameters.

Method 2. Coining with plumbing of linen

Usually such a method is used in the docking of cast-iron pipes, however, it is also suitable for mixed docking. When performing work in accordance with this method, perform the following actions:

- in the area of the joint on the plastic pipe, rewind the plumbing in several layers;

- rewinding with a narrow spatula or a wide screwdriver is tightly pushed into the slot that is between the two pipes (this is the case);

- the transition to the cast-iron pipe is several times smeared with polymer-cement mortar, which includes water, cement and PVA glue;

- after performing sewerage work, it is undesirable to use it for at least the first 24 hours.

The joint thus made is sufficiently reliable. This method has been widely used before the sale of silicone sealants, however, and now it is often used when connecting a plastic pipe to a cast iron under the sink or washbasin. Even a few years after the pipes are joined in this way, if they arise, then, as a rule, not at the junction of the pipes.

Method 3. Sealing with sanitary silicone

If the connection of the plastic pipe with cast iron is accompanied by the formation of a small gap (no more than 2 mm), then this method is very effective. When carrying out the work, special attention must be paid to the tightness of the joint in its lower part.

When performing docking in accordance with this method it is necessary:

- before the docking, the joint is carefully dried, preferably using a building hair dryer;

- with a construction pistol in the gap between the pipes, they drive the silicone, taking into account that the deeper the penetration of the silicone, the connection of the cast-iron pipe with the plastic one will be more reliable,

- layer of silicone should be dried - usually complete drying occurs within 3-5 hours, while a thicker layer dries longer.

Use sewage, until the silicone is dry, is highly undesirable.

Method 4: Combination of the methods outlined above

To increase the reliability of the joint of the plastic and cast iron pipe, it is possible to combine the above methods, for example:

- In the presence of a large gap between the pipes at the junction point, rubber gaskets together with the coil are used. So, when you connect the toilet bowl with a "bayan", that is, a corrugated pipe, use a coiling with linen winding and then cover the joint with a sanitary silicone. At the same time, silicone rubber is greased with a cast iron cross at the junction and rubber seals.

- When coining often used instead of a polymer-cement mortar silicone.

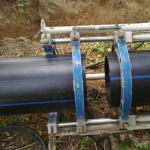

Connection with a press fitting

If a press fitting is used (an adapter for cast-iron pipes with a thread under the cast-iron pipe at one end and a socket for sliding connections of plastic pipes on the other), a patch or Teflon tape is used.

The technology of performing work with a press fitting:

- cut off the old pipe with a grinder or unscrew the coupling on a cast-iron pipeline at the place of the future joint with the plastic pipe;

- the edge of the pipe is lubricated with oil or a solid oil to the point where it leaves the plate;

- thread carving cut the thread, wipe it and wrap it on a patch or FUM tape;

- lubricate the rewinding with silicone;

- the press fitting is wound by hand to the thread (the key is not used so that the press fitting does not crack), it will be possible to twist after the water supply is turned on in case it is necessary to stop the leakage.

Important to remember:

- Docking of cast-iron and plastic pipes with a press fitting should be accompanied by taking into account the difference in the coefficients of thermal expansion of metal and plastic. For this reason it is not recommended to screw the PVC fittings on the metal.

- When installing a heating system or a pipeline for hot water supply, use split brass couplings having a PVC element or couplings equipped with a rubber band.

In conclusion, it should be noted that following the rules that are mandatory for the connection of plastic and metal pipes, it is possible to carry out the work in a qualitative way in the case of repairs, and with the planned replacement of pipes made of cast iron with plastic pipes.

The most popular building material with which water and sewage systems are created are products such as pipes and PVC joints. In addition to their significant advantages, such products have a fairly democratic price, which ensures accessibility for all segments of the population.

What are the distinctive characteristics of the water supply system or the sewage disposal channel, which are connected by PVC products?

Product Description

Polyvinyl chloride (PVC) is a building material related to a thermoplastic, obtained by artificial means. It consists of derivatives of oil and table salt. To the resulting mixture, materials are added that provide the material with strength and endurance. It can be either lead or calcium with zinc. Therefore, it is quite fair to call this material widely functional, strong, elastic, and also absolutely safe for human life and health. It is thanks to all the listed qualities that PVC products are increasingly acquiring their customers.

But, it is necessary to understand that in each situation the issue of choosing this material must be strictly individual. It is necessary to take into account all the nuances and peculiarities in a particular case, since there are also unfavorable conditions for using PVC. As an example, one can consider the creation of channels and systems, which will be constantly affected by mechanical shocks. In such a case, with such a load, PVC products can get serious damage, such as cracking and cracking. Naturally, this will lead to irreversible consequences. For such systems with permanent mechanical loads, it is recommended to use steel products in use.

But, do not be upset. If it is necessary to create a water supply system and there is no way to avoid permanent mechanical impact from outside, there is an option to protect the structure from PVC by a specially designed case.

Advantages of PVC fittings:

1. When installing structures from this material, there is no need to use the electric or gas welding process. All the details of the design are quickly and easily fixed manually. In isolated, very rare cases, an electric tool for channel mounting, for drilling holes in walls, as well as for creating a barrier element of a pipeline product, can be of help.

2. Products made of PVC are easy enough, and accordingly convenient to install. The process of assembly and installation of structures is simplified and does not create additional troublesome processes. In addition, PVC materials can be used in the application to create the product, which must be later installed on the partition walls with unimportant bearing qualities and properties. Such material will not create additional stress on the walls.

3. Products made of PVC show a stable resistance to the occurrence of corrosive formations. But, the main and very important nuance is their steadiness in conditions of unstable temperature, its jumps and drops, in conditions of windy gusts and exposure to ultraviolet rays.

4. Availability of a wide range of connectors. With the help of various fittings, it is not difficult to create a design of any shape and type.

5. Low price. That is, from cheap materials it is possible to make a pipeline of any complexity. Such products of their PVC cost about 30% cheaper than metal products.

6. Long-term in operation. Connectors from PVC can serve, performing their functions faithfully for about 30 years.

Defects and imperfections of products

Of course, with all the advantages and positive characteristics of PVC fittings, there are some negative nuances and imperfections of such products.

- The first drawback is that they do not tolerate a strong mechanical effect, and are therefore susceptible to damage and fracture.

- The second disadvantage is ignorance and misunderstanding of the correct installation and use of such products. Many people who do the construction for the first time, it seems that the assembly process is complicated and incomprehensible. But, having got acquainted with the rules of proper use and installation, it is possible to do everything yourself without the special experience and assistance of specialists. In the instructions for use, there is nothing complicated. With this there will be no problems. But to determine what kind of fitting is needed in a specific case, you need to know some information, at least about what, in general, there are types of connectors and the principles of their installation.

- The third disadvantage is that the level of strength, in comparison with other representatives, is not the highest. This indicates that if cracks and splits occur, the fitting can not be subordinated, it is possible to replace it only.

- Well, finally, the instability of low temperature. Adapters made of PVC can be used in high-quality conditions under temperature conditions up to -15 degrees. In the case of a drop in temperature below this level, their preferential properties may be lost.

So, the transition nodes of polyvinyl chloride, depending on their installation, are:

1. Fittings installed with special adhesives, such as polymer-based adhesives . Such a connection provides the design with absolute hermetic conditions, since the adhesive material acts on the microparticles of the product, thereby leaving no spaces to the slits. Such transitional parts are capable of withstanding pressures of 170 bar. The strength level depends on the parameters of the adapter, the PVC pipe and the temperature regime of the water in the water supply line.

The process of connection is quite simple. First of all, it is necessary to make all sizes and according to them cut PVC pipes. After that, the slices must be treated with sandpaper and with the help of a dry cloth to clean the product, including its internal cavity. Then, by applying a cleansing agent, it is necessary to treat the adapter and the entire surface of the PVC pipe. From the moment of its complete drying, it is possible to start applying the adhesive to the fitting and the fastened section of the pipe. Next, you need to connect the fitting to the pipe by about half and slightly scroll. Such movements will ensure tight fitting of the pipe into the fitting. Hold tightly the connected products for about a minute. After the work done, the remnants of the adhesive should be removed.

2. Fittings with thread and nut . Such connectors are inherent as a nut made of plastic, and made of metal.

3. Fittings installed in an alternative way . This kind of adapters made of PVC pipes has a threaded mechanism of installation, but they can be mounted and with the help of special adhesives. The combination of these mounting methods makes this kind of fittings practically universal. In the case of using both methods, one can simultaneously improve properties such as strength and tightness.

It must be remembered that PVC pipes can also be connected using metal adapters. For example, you can connect a low-pressure polyethylene pipe using a brass fitting. Therefore, taking into account all the features of each connected product, it is necessary to focus on the type of connector that is needed in each specific case.

Transition nodes for PVC pipes, depending on their tasks, are:

1. connectors. Such products are made of plastic and metal and are designed to connect pipes of a wide variety of parameters. In most cases, such connectors have a threaded attachment mechanism. Wide application of this type of fittings has found itself in the creation of gas transmission systems, water supply channels, as well as in the installation of channels that conduct oil products.

2. Connectors having several branches. Basically, they find their use in the process of laying PVC pipes to certain places. For example, this kind of well established itself as a washstand or pallet. The process of fixing and fixing occurs with the use of adhesives or special. In both cases, a high level of tightness is ensured.

3. Corner adapter made of PVC pipes. This kind of product is presented in most cases from PVC, without metallic inclusions. These are connectors without a threaded mechanism, having different appearance and parameters. In addition, the rotation of the angle can be very diverse. Using this type of fittings, you can easily create a design of any complexity.

4. Connector in the form. This view is presented as the simplest form of an adapter having an even shape and intended to combine two PVC pipes with identical diameter. Such products are applicable in exceptional cases, where it is necessary to ensure absolute tightness and strength in conditions of installation by glueing.

So, it will not be difficult to determine the type of fitting you need. The main thing is to be guided by their distinctive characteristics. Having an idea of the types of connectors, you can easily determine their quality properties and choose exactly the adapter made of PVC pipes, which is needed in your case.