Diameters, sizes and prices of polypropylene pipes. Polypropylene pipes - dimensions and classification

Recently, more and more of our fellow citizens are stopping their choice on polypropylene pipes, thereby gaining an opportunity to get acquainted with their inherent advantages. It should be said that these products have standardized characteristics, since manufacturers produce them in accordance with GOST, which fixes the relevant requirements.

So, internal highways reach in diameter of the order of 10-1200 mm. The walls of these pipes can have different thicknesses, which is determined by their design features. Similar products can be classified according to various parameters, which include the composition of raw materials, pressure, purpose.

Analyzing the range of companies involved in the manufacture of polypropylene pipes, it can be noted that these products can have different diameters.

The high popularity of polypropylene pipes explains why they find applications every year in new areas. To date, these structures are used in engineering, agriculture, as well as in heating, water supply and sewerage systems.

The high popularity of polypropylene pipes explains why they find applications every year in new areas. To date, these structures are used in engineering, agriculture, as well as in heating, water supply and sewerage systems.

It is GOST is the main document, which guides the producers, asking at the manufacturing stage dimensions and configuration for these products. The latter can be classified into different species, based on the qualitative composition of raw materials, which is largely formed by the introduction of various additives.

Classification of propylene pipes by composition of raw materials

Classification by pressure

The markings used for polypropylene constructions often contain the designation N25, N10, etc. On the basis of this indicator, what are the capabilities of the material to withstand the pressure of the liquid, which circulates along the highway.

All polypropylene tubular products offered on the market can be classified into the following types:

РN10

The main performance characteristics of these products is the pressure on the wall of 1 MPa, as well as the thickness equal to about 1.9-10 mm. On their basis, often warm floors are arranged, and also cold water supply systems at an operating temperature not exceeding 45 degrees. On the geometry of these structures, we can say the following: the value of the outer diameter is 20-110 mm, the inner diameter is 16-90 mm.

PN16

Products of this type often find application in the main areas. The working pressure for it is 1.6 MPa. These products can be used when installation of cold and hot water supply systems, for which the heating medium limit is not 60 degrees.

РN20

In the process of operation, structures made of polypropylene of this category withstand pressure on the wall at a level of 2 MPa, the wall thickness is 16-18.4 mm. Most often, on the basis of this material, hot and cold water supply systems, in which the temperature of the transported liquid does not exceed 80 degrees. The products are manufactured with an external diameter of 16-110 mm and an inner diameter of 10.6-73.2 mm.

РN25

These products made of polypropylene are designed for a pressure of 2.5 MPa, differ by the presence of a reinforcing layer based on aluminum foil. Most often they are used in the construction of heating systems, as well as devices of hot water systems, which are used for delivery of a liquid temperature up to + 95 degrees. A feature of these structures is the multilayer structure, which allows them to withstand the stresses of thermal and shock character. Finished products have a diameter of 13.2-50 mm, the outer is 21.2-77.9 mm.

Factors affecting the dimensions of polypropylene pipes

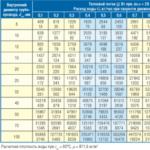

Among the defining parameters are temperature and volume of the medium, for the delivery of which polypropylene pipes are used, as well as the level of pressure on the walls. However, the main focus in selecting a configuration is reversed. All types of polypropylene pipes known at the current time differ in their sizes, which are presented in a clear form in the corresponding table. It is its use that simplifies the procedure for selecting the right product.

An important issue is the correct determination of the size of the main line. When calculating the physical parameters for sewage, heating, and water supply systems, first of all, their purpose is taken into account. If we compare metal and polypropylene pipes, then between them there is a significant deviation in diameter. However, the latter are more preferable.

An important issue is the correct determination of the size of the main line. When calculating the physical parameters for sewage, heating, and water supply systems, first of all, their purpose is taken into account. If we compare metal and polypropylene pipes, then between them there is a significant deviation in diameter. However, the latter are more preferable.

Although the diameter of plastic products is not so great, yet they are noticeably superior to durability in steel analogs. In addition, polymer designs look more attractive and less susceptible to corrosion processes.

When determining the diameter of polypropylene products are guided by the results of calculations of the carrying capacity of the highway. Regardless of the material of the product, a lot of attention should be given to marking. There are separate designs, where there is a designation of the internal diameter, while in others, the manufacturer can specify only the external. If we talk about polymer pipes, then only the outer diameter is given here.

Rules for the selection of the size of the highway

In order to determine the optimum value of the inner diameter of polypropylene pipes, calculations are performed using the initial data as the base:

- The speed at which the medium moves through the pipes;

- The rate of water consumption.

If the object is a private house or mansion, then to determine the diameter of polypropylene products, based on which the water supply system will be arranged, you should use the formula:

D = √ ((4) -Q- (1000 / π ∙ v))

where v is the speed of the passing stream, m / s (it is assumed from 0.7 ... 2 m / s);

π is the Pi number of 3.14.

Directly at the stage of choosing pipes for water supply, they are most often guided by a diameter index of 20 mm.

Directly at the stage of choosing pipes for water supply, they are most often guided by a diameter index of 20 mm.

Its peculiarities of calculating the diameter for polypropylene pipes are available, if it is a multi-storey house. Here, at each stage of construction, the parameter value is adjusted. The reason for this is with differences when putting water in a separate apartment, entrance, house, quarter, microdistrict. The main rule that is observed here: with an increase in the rate of flow of water, the diameter of the main line also grows.

When installing water supply systems for apartment buildings, polypropylene pipes are most often used, with the following dimensions:

- when building risers in five-story buildings - 25 mm;

- when creating wiring inside living quarters - 20 mm;

- when building risers in buildings, providing 9 and more floors - 32 mm.

Polypropylene pipes - dimensions

The largest distribution of large diameter polypropylene structures was obtained with water supply devices, heating systems, and sewage systems designed to solve the problem of water supply for houses, residential microdistricts, public buildings, hotels and other facilities.

Thus, the choice of water supply pipes having a diameter of 500 mm is stopped when must be provided with cold drinking water, supplied from the accumulation basins, the areas of a large city. At the same time, with large polypropylene structures, as a rule, they do not solve the problem of coolant transportation, which is associated with a significant heat load, against which the polymer lines become more elastic.

If there is a problem on the installation of ventilation systems and gutters of industrial structures, then the main element is polypropylene products with a minimum diameter of 400 mm.

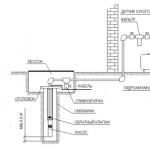

If the owner of a private house or apartment has decided to perform the installation of heating, water supply and sewer systems himself, then he must solve two problems:

- correctly determine the size of the mains;

- correctly implement their connection.

Perform such work is possible only with the availability of special welding equipment, as well as minimum skills for using them. For this reason, it is advisable to assign work related to the development of the communication project and their installation to qualified specialists.

Conclusion

The dimensions of polypropylene pipes are one of the determining factors that can affect the efficiency of the water supply and heating system. For this reason, the choice of these designs should be approached as responsibly as possible. Any error can negate all the installation effort, which in addition may result in an emergency situation.

The dimensions of polypropylene pipes are one of the determining factors that can affect the efficiency of the water supply and heating system. For this reason, the choice of these designs should be approached as responsibly as possible. Any error can negate all the installation effort, which in addition may result in an emergency situation.

The assortment of polypropylene pipes on the market today is huge, because they are very in demand in laying heating systems, as well as water supply and sewerage systems. The most significant parameter of these pipes is their diameter.

Classification of polypropylene pipes

The most common types of polypropylene pipes are divided into three types:

- PPB are pipes with increased impact strength and are used in the arrangement of floor heating systems and cold water supply systems.

- PPH is, as a rule, polypropylene pipes of large diameters, intended for ventilation and cold water supply systems.

- PPR is the most common and popular type of pipe. They are universal, excellent for hot and cold water supply, as well as for heating systems, well tolerating high temperatures.

All classes of the above pipes are made of various types of plastic, minor additives in which can convert polypropylene into a more heat-resistant or more elastic material.

Dimensions and properties of pipes

The length of polypropylene pipes is equal to four meters, but their diameter can be completely different. Polypropylene pipes whose sizes are distinguished by the diameter, are produced with a diameter starting from 20 mm and above.

Pipes, 110 mm in diameter, are needed in various industries, and if they are 200 mm in size, they are used to create structures that require significant flows of people, for example, hotel or entertainment complexes, large shopping centers, hospitals.

The choice of the required pipe is made by its internal size, by calculating the allowable pressure and temperature. There are special tables for selecting the required pipe.

Aggressive chemicals are transported by pipes, 63 mm in diameter. This kind of pipe is indispensable for systems using compressed air. The size of pipes 63 and 25 mm is used for connection with boiler systems, divorce on floors, and also for connection of radiators to the heating system. It does not dispense with such pipes and the installation of warm floors.

In individual construction, polypropylene pipes of dimensions 20-32 mm are ideal. They have a large capacity and can easily take the required shape.

Pipes made of polypropylene can be single-layer and multi-layer. To strengthen them, reinforcement is used - creating a special structure of several layers. Such layers, as a rule, five - between two layers of polypropylene there is a layer of aluminum, connected with plastic by means of 2 glutinous layers. The aluminum layer is made to a thickness in the range of 0.1 to 0.5 mm.

Polypropylene is a durable, reliable, but inexpensive material, whose popularity is growing year by year.

Mounting Features

Pipes made of polypropylene do not bend during installation. They are interconnected by special coupler welding using fittings that have a metal thread for fixing with various devices. Such pipes are successfully used in compressed air systems due to the quality of the welded joint. Before welding polypropylene parts, it must be checked that they are not damaged and do not have any contaminants.

Polypropylene pipes are elastic, having the ability to significantly change their length under the influence of temperatures. Due to this quality, even with freezing of water in such water pipes, they will only slightly change their diameter. And after the melting of the frozen water in such a pipe, it again returns to its former dimensions. With a long product (more than 10 meters), special flexible temperature compensators are used.

Mounting these pipes, it is necessary to take into account, also, changes due to the heat of their linear dimensions. Fixing such a system should not be rigid, it is required to provide for mandatory thermal clearances.

Pipes and parts of polypropylene must be protected from excessive mechanical stress and shock, promptly culling the damaged parts, as well as from exposure to ultraviolet rays. It is for this reason that all components of the polypropylene pipeline must be stored away from sunlight: in enclosed spaces or under a canopy.

To bend the pipe, it is heated with hot air, the temperature of which is about 140 degrees. Over the open fire heating pipes can not be produced.

For heating systems and hot water supply systems, the optimum option will be reinforced pipes, less changing their size under the influence of heat.

The buyer, who visited the supermarket of sanitary ware, literally runs out of sight at the sight of racks with polypropylene pipes.

The size of polypropylene pipes, their color, the armature or its absence, the operating temperature - how in all this not to get confused? Let's try to clarify the situation with the types of pipes.

Application

To begin with it is necessary to be defined by that for pipes we are necessary.

Polypropylene pipes are made for:

- Ventilation;

- Sewerage;

- Water supply and heating.

Of course, the scope of application dictates both the dimensions of polypropylene pipes, and the wall thickness, their resistance to pressure and temperature.

Ventilation

All that is required of these pipes is to ensure the inflow or outflow of air. If so, they do not need much strength, but light weight is welcomed - because ventilation often has to be mounted not on the walls of the capital, but on decorative partitions, and even lay over suspended ceilings.

The dimensions of the ventilation pipes vary depending on the type of premises where they are to be used. The most common pipes are standard five-meter length - longer pipes are simply inconvenient to transport and lay. "Pipe" in this case - the name is very conditional; The ventilation can be in the cross-section of an oval, a square, a rectangle or even more complex figures.

In residential premises, ventilating pipes with a diameter of 100-125 mm are usually used; they are connected, as a rule, without. The pipe is simply inserted into the socket of the previous one.

Sewerage

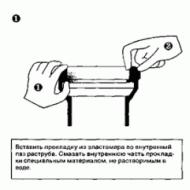

The principle of docking pipes here is often the same as in ventilation; but the joint already needs tightness. It provides a rubber seal ring.

Pipes for internal sewerage are produced in length 0,3 - 2 meters; the most popular diameters are 40, 50 and 110 mm. The sizes of polypropylene pipes for external sewerage are quite different: pipes with a diameter of 150 mm or more are more often used there. Typical length of such pipes is 5 meters.

Pipes for gravity drainage are often produced corrugated and with a small diameter are stored in bays. Corrugation makes the pipe less sensitive to soil subsidence; However, the drawdown, in addition to the probability of damaging the pipe, can also lead to the formation of areas with a negative bias. Of course, this should be avoided: the countercrack is always the place of accumulation of fat and suspensions, which carry sewage.

Tip: gravity sewage is always laid with a slope of 1-2 centimeters per meter of length. Deviations in the smaller and larger sides are equally undesirable.

The maximum diameter of serially produced polypropylene sewer pipes is 600 millimeters. Such pipes are made for inter-house sewers, they are often laid using heavy equipment and have a length of a separate pipe up to ten meters.

Plumbing and heating

Polypropylene pipes have much more modest dimensions: diameter from 16 to 110 millimeters, the length can be very different; most often five-meter.

What other characteristics of pipes for water supply or heating, other than size, should you pay attention to?

- Working temperature. The most common pipes type PPR, which are assured by manufacturers can withstand temperatures of 95 C, in fact, a little more. However, it is possible to meet PPH pipes, designed exclusively for ventilation and cold water.

- Operating pressure. Most likely in the store you will see pipes PN20 or PN25. The number in their marking corresponds to the maximum pressure that they are guaranteed to withstand at normal temperature. If you see PN6 - do not stay at the stand, this pipe is definitely not for you.

- Reinforcement. Pipes of polypropylene dimensions of 16 mm or more can have an additional layer of aluminum foil or a layer of polypropylene in a mixture with glass fiber; thanks to the reinforcement, the pipe is made stronger and less stretched when heated. This is especially important if pipes are heated in screed or plaster.

Special cases

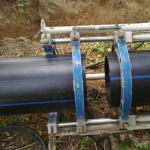

Stand out are the pipes that are used to create external cold water mains. The dimensions of polypropylene pipes here can be huge: the diameter of a pipe of 60 centimeters is not something uncommon. The thickness of the walls is tens of millimeters; such pipes are most often produced by ten-meter lashes.

From the point of view of installers, the features of the polypropylene lines are as follows:

- In places of brisk movement, the pipes lie in a reinforced concrete box. This is done to avoid deformation with inevitable shifts and subsidence of the soil.

- Polypropylene pipe dimensions of 300 mm and more are usually laid down already with the use of heavy equipment. Polypropylene is an easy material; in fact, it is the easiest of technical plastics. At a density of 0.91 t / m3, it is lighter than water. But after all, the volume at a fair thickness of the walls is rather big!

- Forget about the fittings. Large pipes are cooked butt. Strength from this does not suffer again due to the thick walls of the pipes.

Conclusion

Summarizing, let's once again list the characteristics of a polypropylene pipe: dimensions; the thickness of the walls and the associated ability to withstand mechanical influences; presence or absence of reinforcing layer; resistance to high temperatures; a method of joining pipes.

As usual - good luck in repair!

At the design stages of cold and hot water supply points, internal and external sewerage, a properly selected polypropylene pipe is required - diameters, table, price and the required amount of material depend on the destination of the main (domestic or industrial).

Selecting sizes based on pressure

The importance of the choice of PP pipes has a water head. With insufficient pressure, the lines with a smaller cross-section are selected. With an increase in the amount of fluid transported, a larger diameter is required. When studying the marking of PP, special attention is paid to the value of N25, N10, etc. It allows to evaluate the stability of the material, relative to the water pressure in the pipeline. Quality PP pipes serve up to 20 years or more.

Types of PP pipes:

- РN10 - pipes are designed for working pressure of 13 atm. and the thickness of the material is 1.9 to 10 mm. They are well maintained when laying the system "warm floor" and the supply of cold water. The limiting temperature of heating is +45 g. Cross-section of PP pipes: external 2 ... 11 cm, internally 1.6 ... 9 cm.

- PN16 - rarely used version of the structure, providing pressure on the wall 16 atm. It is used for cold and hot water supply with a maximum heating temperature of up to +60 g.

- N20 (РN20) - products with a thickness of 16 ... 18,4 mm are the optimal solution for the arrangement of the heating system and water supply with a permissible water temperature limit of 80 g. Polypropylene water pipe with a pressure level on the walls of 2.0 MPa, characterized by an external diameter of 1.6 ... 11 cm, internal - 1.06 ... 7.32 cm.

- N25 (РN25) - water main with a pressure level on the wall of 25 atm. Due to the inclusion of aluminum in the structure, these products have ideal characteristics in the arrangement of heating systems, where the water temperature reaches up to +95 deg. The multi-layer structure of the structure determines the high resistance to mechanical and thermal stress. Pipes are produced with an internal section of PN25 - 1,32 ... 5 cm, external - 2,12 ... 7,79 cm.

Attention! Marking 10, 20, 25 determines the level of the limiting pressure (kg / cm2) on polypropylene pipes. Dimensions, table, price and duration of operation depend on the material structure and its reinforcement.

The introduction of new technologies made it possible to obtain a new type of reinforcement of polypropylene pipes - glass fiber. It prevents the separation of the water conduit when used, and when laying - the time required to clean the sections after welding. Armored products using a fiberglass mesh are most in demand, thanks to the rapid installation of deformation resistance and a long operational life without repair.

Basic types of section of PP pipes

When performing calculations, the internal and external cross-sections are taken into account. Internal parameters allow you to know the volume of fluid that passes through a certain time interval. External dimensions allow for construction calculations, namely the size of the niche or channel required for the main line. External section parameters are taken into account for the correct selection of fittings in accordance with the internal diameter. All pipe sizes are classified according to the following parameters:

- Small section - 0,5 ... 7,5 cm. Optimum solution for heating, cold water supply and drainage drainage in out-of-town buildings. Pipes with small diameter are placed in the kitchen, in bathrooms and on common risers. The internal section of 3, 2 cm is more common in multi-apartment buildings.

- The average cross section is 8; 9; 10; eleven; 12.5; 16; 20; 25; 31.5 cm. It is used for water supply and sewerage. The internal section of 8, 9 and 10 cm, serves for the movement of chemical products.

- Large cross-section - 40 cm and more. It is used for water supply and ventilation.

The marking of the pipes is in inches and in mm. For convenience, you can use the conversion table:

How to determine the diameters of the PP line, based on the thickness of the wall?

At the design stages of the pipeline, it is necessary to determine the diameter of the structures in certain sections. For this, a special hydraulic calculation is used, which helps to save on buying. As a result of the calculations, the pressure and the configuration of the trunk are taken into account. Increased parameters do not harm, but will affect the increase in costs. Too small a diameter will provide a weak head.

The diameter of the PP pipes varies from 1.6 to 120 cm:

- For the construction of water pipes and heating of living quarters, constructions with a parameter from 1.6 to 3.2 cm are used.

- For laying the internal sewerage system - 4 and 5 cm or 11 cm.

- The maximum dimensions of PP pipes are relevant when placing an external sewage line of multi-storey buildings.

- When developing an internal water main, the length of the main and the number of points for water supply are taken into account. The feed pipe has a diameter of 3.2 cm, for wiring in buildings the outer section of the PP pipes is 1.6 - 2 cm.

Separately, the thickness of the walls influencing the inner diameter of polypropylene pipes for heating is taken into account. Table with markings of household products (cross-section from 16 to 110 mm) will determine the dependence of the parameters:

How to determine the patency?

To properly calculate the cross-country capacity, the outer section is not taken into account. When calculating the internal section, you need to know how much fluid is transported over a certain period of time.

Factors affecting the patency:

- Inner diameter (small cross section affects the resistance of the walls and the slowing of the flow).

- Pressure on the walls.

- The length of the main (with increasing length increases friction, reducing the flow rate).

- Material (smooth inner coating affects the speed of transportation).

- Duration of operation, which allows you to determine the amount of deposits.

- The number of transitions from one section to another and turns.

For the domestic highway, a simple formula is used to calculate the permeability of the pipeline:

Where Q is the calculated level of load on the section of the highway,

V - speed of water transportation in the pipeline.

Δt is the difference between the heating of water in the feed and return.

There is one more formula:

The calculation is based on the total amount of fluid Q being transported and its speed V. To determine the last parameter, the values 1.5-2 m / s are used for pipes with thick walls and 0.7-1.2 m / sec for thin walled pipes . Since the PP has a smooth inner coating, the calculations use the highest rates of fluid transport. This minimizes frictional losses. More accurate calculations are made in multi-storey buildings. When settling down the risers, the inner section is more often selected within 3.2 cm.

Correspondence of section:

- For an outer section of 1.6 cm, an inner diameter of 1 cm corresponds to the inner diameter.

- For an external section of 2 cm, the optimal solution will be a pipeline with an internal diameter of 1.5 cm.

- For outdoor parameters of 6.3 cm, pipes of 5 cm (inside the structure) are suitable.

- With external dimensions of 12.5 cm, the inner dimension is 10 cm.

Large pipes are used for cold water supply and external drainage system (their padding is not allowed for hot water supply). To supply water to the entire microdistrict, pipes made of PP with a section of 50 cm and more are used.

For small houses and apartments, a minimum number of parsing points is required, which eliminates the need to calculate the exact dimensions of polypropylene pipes in mm.

The contour section table is used taking into account the diameter of the pipes, relative to the mixer:

- With the arrangement of household communications, it is sufficient to purchase PP pipes for heating with a cross section of 2 cm.

- For the supply of cold water, lines with a diameter of 1.6 cm are used.

- Large diameter (from 50 cm) is not required at all.

Dependence of pipe size on material

Based on the technical characteristics of the material, the following types of pipelines are distinguished:

- PPR (PPRS, PPR) - for the production of pipes a static copolymer of foam (or random copolymer) with a crystallized molecular composition is used. They can withstand a wide range of heating / subcooling from -165 to +1410 C and shock loads. This determines their wide application for drainage or heating systems in the domestic sphere. Their parameters vary in the range of 1.6 ... 11 cm and are selected taking into account the pressure to which they are calculated.

- PPH. Polypropylene pipes are created using modified components: antistatic agents, flame retardants and nucleators, which impart a high level of impact strength to the polymer. The structures serve for external water supply, ventilation and sewage systems. They exclude the possibility of laying the heating main, which is explained by the low melting point. A large cross-section of PPH pipes ensures their use in an industrial drainage system.

- PPB (linear copolymer). By its structural properties, this raw material is characterized by the presence of microscopic molecules of a homopolymer (blocks) having a different structure, composition alternating in a given order. Due to the peculiarities of the molecular structure, these pipes have high impact resistance and are well used for laying the "warm floor" system or the supply of cold water to the house.

- PPs (semicrystalline structural polymer) - a material with a special molecular composition. Has a high resistance to mechanical and thermal stress, wear. The cross-section of pipes varies from 2 to 120 cm. Their installation is recommended for ventilation and heating systems, as well as for water supply.

Welding of pipes

The heating of the welding machine for PP pipes is 250-260 C. After reaching the set temperature (for 10-15 minutes), two elements are prepared for the connection and simultaneously attach the contours to the welding nozzles. Gradually, without turning, they are pressed into the nozzles of the soldering iron to mark the specified depth of welding. From this point, you can start counting the warm-up time. At the end of the process, remove the products from the heating parts immediately, without any twists and turn the connection to the previously marked depth.

It is not recommended to push the contour into the shaped part very deeply, which will affect the overlapping of the water current. When fusing parts, a rigid fixation or adjustment of the connection is required. At the end of the melting of the elements it is necessary to allow the joint to cool, which forms a monolithic construction of a water or heating system. The welding time, based on the cross-section and the depth of the thermal impact, is indicated in the tabular data:

How much do household pipes cost?

Cost of pipes with a large cross-section

According to GOST 18599-2001, the use of highways is permitted when installing or changing the water supply, setting up a water drain, a swimming pool or lifting water from an artesian spring. HDPE pipes are used for laying on straight sections of 120 cm and coils of 1000, 2000 cm. They are characterized by a smooth inner and outer covering. The rules of SNiP allow the presence of defects within the limits of permissible deviations, the possibility of the formation of bubbles or cracks, external inclusions is excluded.

Pipes with a large diameter are classified on the basis of the regulated parameters that determine their purpose.

Labeling of polyethylene pipes: PE80 and PE100. The first variant is characterized by excellent consumer properties for a small-size main (up to 90 mm). The marking PE100 determines significant savings on the material when laying a pipeline with a large cross-section. The indicator of the resistance of the HDPE highway to the wall pressure (SDR) is separately taken into account, it is calculated by simply relating the cross-section of PE pipes to the thickness of the panels. Together with the decrease in the value obtained, the index of strength increases.

Video

Polypropylene pipes in construction today are just as common as a mobile phone in society, although polypropylene on a large scale began to be produced in Russia only about 30 years ago. Today this material is the second most consumable among polymers in the world, and polypropylene pipes, the sizes of which will satisfy any requirements, persistently replace the metal analogues.

1 Polypropylene pipes - specifications

In almost all cases, the characteristics of polypropylene pipes are better than those of steel or cast iron analogs, especially this applies to the installation of water pipes in both residential and industrial buildings. Undoubtedly their advantage is a long service life, which nominally exceeds 50 years for cold water and is not less than 25 years for hot water. Of course, these figures take into account only the correct operation. Low thermal conductivity of polypropylene is the second factor, because of which the material has become so popular. Pipes from it practically do not lose heat and, moreover, do not conduct electricity.

In comparison with the same metal analogs, polypropylene creates acoustic insulation, drowning out the noise of the liquid flow and not resonating with hydraulic shocks. The material itself is completely ecological and safe for humans and animals, the inner surface of the pipes much better inhibits the development of bacterial colonies, as well as the deposition of organic and inorganic substances. Simply put, thanks to a smooth surface, such pipes are less likely to clog, and the water in them is cleaner. Polypropylene is resistant to corrosion and resistant to aggressive chemical environments.

In addition, pipes from this very light material are extremely economical, as well as the tools needed to work with them. You will not even need it - it will be replaced by a regular hacksaw. Installation of polypropylene products is carried out up to 7 times faster than is possible with metal mounting! To weld it, no dangerous equipment is required that can cause a fire or explosion, and welded joints are completely leakproof. Despite the fact that welding requires a high temperature, causing the melting of polypropylene, during installation there are no harmful substances that can affect the human body.

Polypropylene, moreover, is still very plastic material, however, the lower the temperature, the lower this characteristic.Therefore, when installing in a room should be at least +5 ° C, otherwise the pipes will simply be unbreakable, and the quality of the connections will not be at an altitude. For convenience of work with such pipes without additional heating in the room should be a temperature of not below +15 ° C. When working, it is necessary to remember the maximum bending radius set by the manufacturer - for a pipe of 16-32 mm it will be equal to its 8 diameters.

Basically, the whole minus of polypropylene pipes is reduced to limiting the temperature regime and, together with it, the maximum pressure. Long-term operation of a water pipe made of polypropylene is possible at a water temperature of not more than 95 ° C.

So, using such pipes for heating in a multi-storey building, specify the maximum temperature it reaches and under what pressure is applied to you.

Disregarding this question, be prepared not only for the appearance of so-called "hernias" on the tubes themselves, but also for emergency disconnection of heating in your apartment if such a hernia also breaks through. Especially often this happens in houses close to the boiler room. By the way, the nominal minus temperature, which polypropylene products can withstand -10 ° С. At the same time, for the pipes themselves, there are no threats of rupture from the internal pressure created, since the expansion coefficient of polypropylene pipes is 0.15 mm / m ° C.

2 Polypropylene pipes, sizes, categories and methods of reinforcement

The internal diameter of polypropylene pipes, as well as the thickness of the walls and methods of strengthening are key values for dividing them into categories. The most common in construction work are three categories:

- PN10 is a category used for installing a cold water pipe, as well as for installing warm floors. Nominally withstands a temperature of up to +45 ° C and a working pressure of 1 MPa. In this group, the thickness of the walls is from 2 millimeters to 1 centimeter. Outside diameters of pipes - from 20 to 110 mm, internal - from 16 to 90 mm;

- The PN20 is a station wagon that can be used in both water supply and heating and heating, provided that the water temperature does not exceed +80 ° C and the pressure is 2 MPa. The internal diameters of the PN20 range from 10.6 to 73.2 mm with the outer 16-110 mm. Consequently, the thickness of the walls is within the range of 16-18.4 mm;

- PN25 - this category of pipes is also called reinforced. Closer to the outside, the PN25 has an interlayer of sheet metal, fiberglass or composite. This method is used to enhance their stability at high temperatures (+95 ° C) and pressure (nominal pressure - 2.5 MPa). This category is designed specifically for heating systems.

In total, there are five types of reinforcement (reinforcement) of polypropylene products. The first method involves reinforcement with a single sheet of aluminum foil, which is applied to the outside of the pipe. The second method also consists in reinforcement with aluminum, but unlike the first variant, the metal sheet is perforated. The third way of aluminum reinforcement is to place aluminum closer to the inside.

The fourth type of reinforcement is reinforcement of the product with glass fiber located in the middle between the outer and inner layers. And the most effective way to strengthen a polypropylene pipe is reinforcement with a composite. A composite is a mixture of polypropylene and fiberglass, which is laid between the inner and outer surfaces.

The maximum service life of polypropylene pipes rarely depends on the manufacturers, but depends more on factors such as temperature and pressure inside them. It is permissible to exceed one of the parameters, but exceeding both is fraught with consequences. For example, at low pressure, polypropylene will be able to withstand a temperature much higher than the nominal, and serve a considerable period. Similarly, in a situation where the pressure exceeds the nominal, but the temperature remains low.

3 Choosing a pipe - what to look at?

In the market you can find polypropylene pipes of various colors - from green to white. By and large, it does not matter what color they are, except that black color is more resistant to ultraviolet radiation. In the rest, the conditions of installation, operation and cost are no different.

When choosing polypropylene products for heating, one should take into account not so much their quality as operating conditions: water temperature, working pressure in the pipeline. That the heating system has served you all 50 years, the maximum pressure in the system should not exceed 6 atmospheres, and the temperature should not rise above 80 ° C.

The mounting of the pipe is of great importance during installation. It means that with temperature changes polypropylene products can change their length, hence the internal pressure can be greater than the working pressure of water. When designing and installing this factor is often not taken into account by inexperienced builders, which can lead to a significant reduction in the life of the products.