Pvc ball water tap drawing. Ball valves for water supply: device features and operation

Add to bookmarks

Depending on the purpose and diameter of the pipelines, as well as the operating environment, the cranes are made of cast iron, brass, bronze, steel, titanium, polyethylene. Ball valves made of brass are compact, convenient and aesthetic, therefore they have deserved recognition among consumers and are presented in a wide range in the market. They are installed mainly on in-house water supply and heating networks. But not all the products that enter the markets can be considered qualitative.

The best quality shut-off valves for domestic distributors are the products of Italian companies. The quality of Polish, Turkish and Chinese firms is much lower. The valves produced in Italy are usually performed by the hot pressing method, which ensures the homogeneity of the structure of the product, and therefore improves its reliability. Chinese and Turkish products are usually made by casting. The accuracy of the design, as well as the quality of the gaskets ensuring the tightness of the valves, is much higher in the products of Italian firms.

Types of materials for ball valves: (cast iron, brass, bronze, steel, titanium, polyethylene).

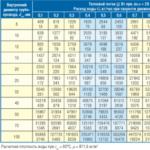

Brass and bronze usually use a shut-off valve with a nominal flow of DN less than 50 mm for pipelines, including low-pressure gas at temperatures below 150 ° C.

But the more expensive and reliable are made of stainless steel. For pipelines operating under impact conditions, standards recommend the use of stop valves made of cast iron.

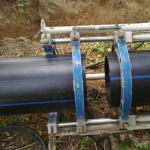

Polyethylene cranes have recently become widespread. The polyethylene gas tap does not have metal parts. It is much lighter than similar metal products, it is simple and reliable in handling, besides, its strength and resistance to mechanical influences can be well characterized. The ball valve is an economical option for most types of pipelines. The use of polyethylene shut-off valves on gas pipelines simplifies network maintenance. Installation of polyethylene cranes is done by the butt welding method or is equipped with couplings with embedded heaters. Thus, fast and reliable welding is carried out.

In accordance with GOST 4666-75, all stop valves must have a distinctive color. The body and covers are painted in a color corresponding to a certain metal. Cast iron products are painted black, from carbon steel to gray, from steel to corrosion-resistant steel to blue; of alloy steel - in blue.

Details of fastening to the pipeline are welded joints, flanges, couplings and heads. For tubes with a conditional pass up to 4 - 45 mm, it is advisable to use a coupler ball valve attachment. Crane ball flanged valves are used for installation in pipes with a diameter of more than 45-50 mm. Flanged joints of the ball valve with the pipe withstand considerable loads. They are highly sealed due to the use of modern sealing gaskets.

According to the requirements of GOST R 52760-2007, the marking of the shut-off and control valves should be made on the body or on the name plate, securely attached to the product.

The marking of the product must contain the following information:

nominal diameter DN (nominal pass), nominal pressure PN, housing material, manufacturer's trademark; an arrow indicating the direction of flow of a liquid or air medium; maximum temperature or range of permissible temperatures, working or design pressure, year of manufacture.

Brief explanation of the meaning of individual terms

In accordance with GOST 28338-89, the nominal diameter DN is a parameter used for piping systems for the characteristics of the elements to be connected. Indicated without designation units and is approximately equal to the inner diameter of the pipes to be connected, measured in millimeters. The exception is plastic pipes, in which the nominal diameter is taken as the outer diameter. According to GOST 26349-84, the nominal pressure PN is a constant internal overpressure of the medium, which pipes and fittings can withstand for the entire service life (50 years) at a water temperature of 20 ° C.

The main advantages of modern ball valves are: high tightness, small dimensions, high wear resistance of the ball, simplicity of design, rate of change in operating mode (overlapping of gas and water flows), low operating costs, low accident rate, easy control - 90 ° turn.

The design of the housing provides this element of reinforcement ease of use, even when it is installed in a virtually inaccessible place. A wide range of ball valves, presented in the modern market, allows you to choose those that are best suited for solving the tasks.

The efficiency of pipelines for various purposes depends not only on the condition of the pipes, the connecting elements, but also on the quality of the locking system. If previously used conventional valves for closing and flow direction, now everywhere there is installation of ball valves.

These products have good quality and high reliability in modern piping systems with various working flows: from household use to pumping gas and petroleum products.

Due to its high quality, the scope of ball valves is quite wide:

The principle of the ball valve

Ball valves are designed to completely cover the working flow in the pipeline. They are not used to adjust it.

In the basis of the operation of such a crane is a metal ball with a through hole.

When the hole is turned towards the pipe, the tap is open. If the ball is turned perpendicular to the tube, it is closed.

The shape of the hole in the balloon can be in the form of a circle, a rectangle, a trapezoid or an oval. And its size depends on the type of pipes and the purpose of the crane.

The locking element of the ball valve can be placed, depending on the size and purpose of the stop valve, in two ways:

- installation of the ball on special supports is used in large cranes;

- for small devices a floating ball is used.

More rarely, the locking element (ball) is installed with additional seals. The operation of the ball valve is fairly simple and is made by turning it 90 degrees.

Types of ball valves

Depending on the installation method, the ball valves are of the following types.

Ball coupling crane it is mainly used in gas pipeline, heating and water supply systems in residential and public buildings. Such devices are small in size, reliable and convenient to operate. Ball type ball valves are used for installation in pipes up to a diameter of 45 millimeters.

For large pipelines, ball valves of flange type.

Flanged ball valves are installed on pipes with a diameter greater than 45 millimeters. When installed in a similar faucet, sealing gaskets are installed, by means of which a high level of strength, reliability and tightness is achieved at the junction of the pipe with the crane.

Ball valves of flanged type are resistant to high loads, high pressure of the working medium and are very strong. Such devices are widely used in gas pipelines and for petroleum product transfer systems. They can be demountable and with a monolithic body.

Spherical crane It is used in pipelines of food and chemical industry and other industrial branches. The crane has great dignity - a wide possibility of repeated dismantling.

Ball valve welded differs from other similar elements in that it is installed in places where subsequent dismantling is not provided. Such a ball valve is mounted using the welding method by highly qualified specialists. Typically, a welded ball valve is used for construction work.

The ball valve combined is different from other devices in that it can be connected to pipes using various methods.

In terms of the number of connecting pipes, ball valves are manufactured in the following types:

- passing devices, that is, one input and one outlet pipe are connected;

- devices of angular type are installed if a bend or turn of the pipeline is necessary on the crane;

- device with a number of tapping more than three. The installation of such elements occurs in order to redirect or shift the flow of the working medium of the pipeline.

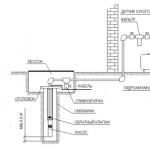

There is also a ball valve for mounting under the ground. It has a high valve axis, which allows it to be used in underground pipelines. The axis with the handle of the ball valve is above the surface of the ground, that is, it can be turned on and off remotely.

Advantages of ball valves

Advantages of such devices are high reliability, practicality in use and compact dimensions. Such devices are broken very rarely. Ease of use is that to turn on you do not need to turn the valve long, but only by turning it 90 degrees you can easily and quickly open or close the movement of the working flow moving through the pipeline. Especially it is convenient in the event of emergency situations.

Ball valve compared to other locking devices has a high strength and corrosion resistance. It is widely used in pipelines for the delivery of chemically aggressive substances.

Thanks to its excellent characteristics, repair and replacement of the ball valve is simple and convenient.

Installation of ball valve

Before installing the ball valve, it is necessary to select the correct location so that installation problems do not arise, and the movement of the pivoting arm does not interfere with other devices. The diameter of the pipe must correspond to the size of the crane.

The ball valve is available with two types of flanges: with external and internal thread or a combined type.

Installation of ball valves in heating batteries or other household devices is performed using various types of flanges.

In doing so, the direction of installation of the crane should be observed, on the body of which there is a special arrow indicating the direction of the water flow.

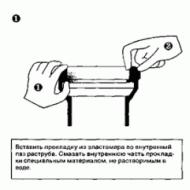

It is necessary to connect the tap when using a special tape or tow, so that no water leakage occurs during operation. The tape needs to be wound in the direction of twisting the crane, otherwise a reliable connection may not work.

The construction of a water supply or heating system in both a private house and an apartment is impossible without using a stop valve. One of the most widely used elements of water supply systems is a brass ball valve. It can be used in various sections of pipelines.

General principles of construction of water supply system

Of course, the construction of water supply systems is a business for which it is better to take professionals. Not without reason in any building university there is a faculty, which is called "Water supply and sewerage". But at the same time, if you have the minimum necessary knowledge, you can create an internal sewer system and supply it with all the necessary devices yourself. In addition, knowledge in the design and construction of water pipes will help you not make mistakes when controlling works produced by outside organizations or masters.

So, in order to build a water pipe with your own hands, you need to work on the following stages.

We draw up a scheme and plan for the future water supply

The initial stage of any construction work is the drawing up of a plan.

The best option would be to draw up a plan for engineering communications, either in a specialized computer program or on a regular sheet of millimeter paper. Typically, water supply communications pass through the walls of the premises, and in some cases are built in stitches - hollowed out in the wall niches.

At this stage, you can calculate the required number of water supply pipes and associated fittings.

An important role in the planning of the water supply system is the calculation of the necessary number of stop valves. As a rule, modern water pipes are constructed of metal-plastic pipes. They are small in weight and easy to install. It is recommended to install classical shut-off ball valves made of brass or their alloys on such pipes. Such material of manufacture is absolutely neutral and does not enter into chemical reactions with flowing water. Because of this, water does not receive additional impurities, and brass ball valves do not oxidize when passing through the liquid.

The device of the ball valve

Locking and distributing water supply on the basis of balls invented about a century ago and during this time was very widespread. Such devices can now be used both in industrial enterprises and in private households.

The main sphere of application of cranes with spherical mechanisms is a complete closure of the water supply pipeline. Therefore, they are installed on the outlets from the main water supply channels or in places where temporary disassembly of hydraulic engineering devices is possible.

The most obvious places for installing a ball valve are:

- the place of connection of a flexible toilet bowl in a bathroom;

- the place where the tap is connected to a dishwasher or a washing machine;

- the connection point of the heating boiler;

- also, shut-off valves with ball valves can be installed on the heating system at the "bypass" connection - the bypass that is installed next to the water pump;

- in addition, the ball valve is installed in the conventional water taps, which are placed on the sinks and bathtubs.

A water distribution valve with a ball valve for pumping has a housing and a rotatable distributor element in its design. The design of the spout of a crane (its body) usually differs significantly depending on the manufacturer's preferences, but the ball element for all modifications is the same.

In such cranes, the distributing element has a cavity inside, at the opposite ends of the hollow ball there are holes: two on one side and one on the other. Through two holes hot and cold water enters, in the cavity of the ball the flows are mixed and the water of the desired temperature is fed into the spout.

In the valve, a hollow ball is also used, only on each side it has one hole. The cross-section of the holes in the ball is usually equal to the internal section of the pipeline, therefore such cranes are called full-bore. In the normal, open position of the tap, the hole in the ball leaves the water passage completely open, and when the ball is rotated 90 degrees, the flow of water completely overlaps.

Why are ball valves widely used?

Locking and draw-off valves with ball mechanisms have gained great popularity due to a combination of several factors:

- long term of trouble-free operation;

- excellent tightness - the outer part of the valve body is a single unit;

- attractive appearance;

- it is enough to fix only the inlet and outlet pipes to the threads.

Attention! Despite all the obvious advantages of ball valves, they are not recommended for installation on piping systems, in the flow of which there is a large amount of debris or foreign impurities. The ball device fits snugly against the fluoroplastic liners inside the casing and damage to their articulation can cause inadequate operation of the device.

What are ball valves manufactured from?

All ball valves manufactured by modern industry can be divided into three large groups according to the materials of their manufacture:

- steel - most often used carbon steel with alloying additives, resistant to corrosion;

- alloys based on copper, in particular brass. The use of such alloys on copper pipelines prevents the appearance of electrochemical corrosion;

- plastic materials - the wide development of polymers has led to the fact that by their qualities they began to come close to metals.

Stop valves made of plastic

Polyethylene or polypropylene is used for the manufacture of stop valves made from polymeric materials. Such a material is absolutely insensitive to corrosion, both chemical and electrochemical. Such cranes are usually installed on systems designed to move corrosive liquids.

A significant disadvantage of plastic as a material for manufacturing stop valves is its inability to use in hot water and heating systems - hot water has a destructive effect on plastic.

Shut-off valves made of steel

Shut-off valves with ball valves are used in industrial pipelines. They are widely used in the transport of liquids heated to high temperatures and even steam. Also, the use of steel ball valves is allowed in pipelines where the liquid moves under pressure.

Brass Ball Valves

The most common for household use ball valves, made of brass - an alloy based on copper. There are two main ways of manufacturing brass ball valves: they are cast into molds or forged using mechanical presses. Forged and more reliable cranes are considered to be more reliable and reliable. The reason for this: with this technology, no air cavities are formed in the mass of the alloy.

The composition of the brass alloy includes substances with different electrochemical potentials. Therefore, in order to avoid chemical corrosion, the products are galvanized, applying a thin protective layer on them.

Attention! The use of ball valves with a working mechanism based on brass is not allowed in pipelines where the temperature of the working medium should not exceed 150 degrees. Too hot liquid forms the smallest cavities in brass, which leads to a significant increase in its brittleness.

Useful tips for the purchase of a quality crane with a ball mechanism

When choosing valves with ball mechanisms, regardless of the materials from which they are made, we recommend using the following algorithm:

Installation of ball valves

The technology of installation of ball valves will differ depending on the material of the manufacture of pipelines. Thus, polypropylene pipes are connected with each other using a special heating device. Copper pipelines are connected by soldering, and steel pipelines are mounted either by welding, or by means of connecting elements on the thread.

Be sure to seal the connections when installing the crane. For this, you can use both traditional linen tow, and more modern elements - fum-tape or sealant.

After the installation of the crane, a water tightness test is performed in the water supply or heating system. Start up the water in the system and place a piece of toilet paper or a paper towel under the mounted faucet. If the connection has the slightest leak, you will immediately see a drop of moisture on the paper.

![]()

As you can see, the choice and installation of a ball valve in a tap can be completely done independently. When selecting a ball valve, pay special attention to its characteristics and appearance, and during installation ensure complete tightness of the connection, then the valve will serve you for many years.

In more detail with ball brass taps, features of their selection and installation you can find in the training video.

Video - Crane ball brass

![]()