The diameter of the pipe for ventilation in a block of flats. Ventilation pipe for extraction: features flat and round

When planning the layout of buildings and various institutions, as well as individual buildings, one of the most important areas of design remains the creation of proper ventilation.

For the installation of the ventilation system, it is necessary that the vent pipe is selected correctly. For this you need to consider the following parameters:

- overall dimensions;

- material of manufacture;

- operating conditions.

The industry produces air ducts of several types:

- round;

- rectangular.

The ventilation pipe is installed in the supply system and with extraction, when a forced and natural form of traction is created.

The ventilation pipe is installed in the supply system and with extraction, when a forced and natural form of traction is created.

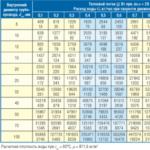

An important point in the purchase of products is the diameter of the ventilation pipe. Today, 22 diameter round products are standardized. Diameters are in the range of 100-2000 mm.

If the outer dimension of the product exceeds 500 mm, it is considered particularly large. The regulations permit the construction of straight lines starting at 2.5 meters. The total length of the straight section should not exceed 6 meters.

The production of ventilation pipes is realized from a whole sheet of metal. The longitudinal seam is formed by a spiral-wound method, when a steel band is wound, so-called strips.

The cost of a circular duct is always less than the cost of rectangular products, since their mass is much less.

The rectangular exhaust pipe is available in several standard sizes:

- 100х150 mm;

- 1600х2000 mm.

All products are incubated with a 50 mm pitch. Trunk sections may be made straight, but not exceeding 2.5 meters. To connect different sections of the duct in places of bends and bends, the industry produces fittings for ventilation systems having certain diameters and various shapes.

Such rectangular ducts are made of sheet steel, and the sheets can be galvanized or rough. For the assembly, metal corners, obtained by stamping, are also used.

Such rectangular ducts are made of sheet steel, and the sheets can be galvanized or rough. For the assembly, metal corners, obtained by stamping, are also used.

A very important advantage of such a rectangular design is the ability to change the configuration of the tubes without violating their throughput. This makes it possible to mount ventilation in buildings where ceilings are very low or in other particularly difficult conditions.

The shape of this product, its cross-section, is directly dependent on the type of room and its dimensions. If the room has a small area and fairly low ceilings, it is more acceptable to consider flat ventilation ducts for drawing rectangular type.

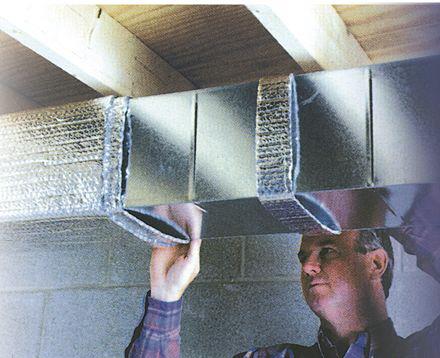

Of course, aerodynamic characteristics of round products are much higher than rectangular. But the available areas dictate their conditions. In rectangular pipes, angles become a source of resistance. They cause a lot of noise, because of them the air speed falls. To extinguish all these negative phenomena, ventilation from rectangular pipes must be isolated.

When industrial ventilation is installed, only round cross-sections are produced, which have a high throughput.

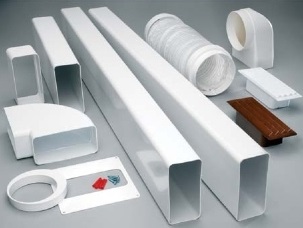

Plastic ventilation pipes

The main material for the manufacture of ventilation pipes is steel and plastic. These materials seem to constitute an unofficial competition to each other.

Which products are more suitable for the ventilation system, steel zinc-plated or conventional plastic? To answer this question it is necessary to take into account the requirements of the project, to consider in detail the nuances of the surrounding atmosphere.

The following materials are used for the manufacture of plastic pipes:

- polypropylene;

- fluoroplastic;

- polyurethane.

In small rooms and individual cottages, ventilation is usually made, made of PVC pipes. They are not expensive, they are easy to install and maintain. For such exhaust pipes for ventilation are not affected by ultraviolet rays, and they are able to withstand a wide spread of temperature. The range is 0-80 degrees.

Advantages of PVC ventilation pipes

- ideal tightness;

- aerodynamic noise meets sanitary standards;

- the cost of such products is much lower than the metal counterparts;

- the appearance is well combined with the interior of the room;

- different sizes and shapes. Easily fit into any system;

- thanks to a large number of additional plastic parts, it is possible to assemble an air duct of any shape;

- completely safe for the human body;

- there is no release of toxic substances.

Polyethylene pipes for the installation of ventilation systems are manufactured with special antistatic protection. They can be operated in a range from 40 to 80 degrees.

PVC pipes, which contain black carbon, are reliably protected from ultraviolet rays. They differ from ordinary products in their black color.

Products made of polypropylene do not react to the influence of an aggressive environment, they are not afraid of high humidity, they are able to work at temperatures from 1 to 98 degrees.

On special areas, special incombustible and antistatic products are used. When the temperature decreases, the material of the article becomes very brittle and brittle. It can only be used in heated rooms.

The most resistant to aggressive media are fluoroplastic tubes. They are installed on any type of ventilation. This material is able to function normally at 40-140 degrees. Such properties made it possible to establish this ventilation for strong air currents, which contain a large number of corrosive substances.

All of the above advantages have made plastic pipes quite popular in individual housing construction. Only low fire resistance does not allow installing PVC pipes in large industrial enterprises.

Steel

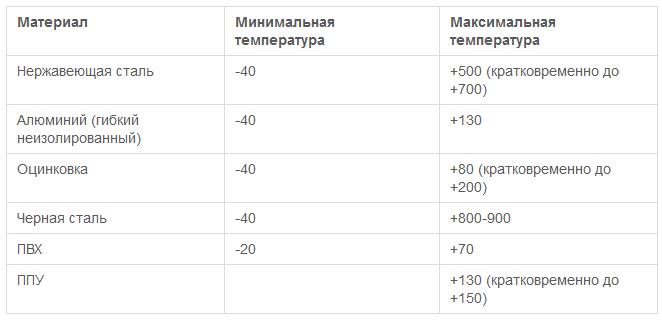

They are made of very different metals and alloys:

They are made of very different metals and alloys:

- sheet galvanizing. Usually the thickness is in the range of 0.5-1.2 mm;

- stainless steel AISI 304, 321, 316, 430. The maximum thickness of 5 millimeters;

- aluminum;

- galvanized steel;

- thin sheet.

For the production of the ventrub pipe, aluminum sheets are rarely used, mainly foil is used. Of the tin, vent pipes are produced, with a diameter of less than 50 cm and a thickness of about 0.55 mm. For large diameters, metal sheets are used, with a thickness of more than 0.7 mm.

Advantages of rigid steel pipes

- Long service life.

- High strength.

- Excellent aerodynamics due to an ideally smooth inner surface.

- Rarely clogged.

- They work at high temperature.

- Withstand a lot of pressure.

- They meet all hygienic requirements, therefore they are installed in areas where high sanitary requirements must be observed.

- Neutral to aggressive substances.

Comparative characteristics of ventilation pipes

Zinc-plated. GOST permits to install galvanized pipes in any climatic conditions. They can be in any ventilation. The only exception is only the transportation systems of aggressive mixtures, for example, gas.

Zinc-plated. GOST permits to install galvanized pipes in any climatic conditions. They can be in any ventilation. The only exception is only the transportation systems of aggressive mixtures, for example, gas.

They are reliably protected from corrosion by a thick layer of zinc. When it comes in contact with oxygen, a protective film forms, which covers the entire surface of the tube.

Stainless steel. Such products are specially manufactured for air ducts, through which aggressive air streams are transported, for example, hot steam or gas.

Stainless models are able to withstand a very high temperature. The life of such structures is measured in tens of years. They are most often installed in large industrial enterprises.

To increase fire safety, products are covered with mineral wool.

Black metal. Such ventilation pipes are installed to ventilate the room and remove flammable gases. They are distinguished from analogues by high fire resistance. Rigidity of pipes is much higher than galvanizing and stainless steel. High sealing is provided by welded seams.

Characteristics:

- Manufactured from steel with low carbon content;

- Wall thickness 1,2-1,5 mm;

- The total length of the pipe varies in the range of 125-250 cm;

- The docking can be done in a flanged way.

Corrugated

Are used to create a flexible duct. The main advantages of such products are:

The corrugated pipe can easily be bent irrespective of its cross-section. Therefore, it is used in rooms of complex configuration, where it is impossible to lay other types of pipes.

It comes in several forms:

- the zinced;

- aluminum.

Distinctive properties give each type of pipe the material of manufacture. A flexible duct has found wide application in industry and individual construction. It is very easy to install by yourself.

Polyester fabric

Advantages of such venttubes include:

Advantages of such venttubes include:

- light weight;

- easy transportation;

- simple installation.

Such ventilation is lightweight, so it is not necessary to install special brackets for wall mounting. Pipes are connected by ordinary lightning, sewn into the end of each section.

Condensation never appears in the garments. Therefore, they do not require warming.

From the above it becomes clear that any kinds of products are very different from each other. Each of them is distinguished by its positive and negative characteristics. But they are united only by a variety of sizes:

- round and plastic - 32-1250 mm;

- metal - 50-1500 mm;

Sewer

If we consider the technical characteristics of sewer and plastic pipes, you can find a lot of similarities. Consumers often ask: Is it possible to independently ventilate using sewer pipes? Will the positive result be achieved?

It is difficult to answer this question unambiguously. This decision can be made only by the owners of the premises.

It is difficult to answer this question unambiguously. This decision can be made only by the owners of the premises.

The most difficult thing when laying such ventilation is the discrepancy between the overall dimensions of all the parts. Typically, the diameters of pipes of different types do not match their dimensions.

When installing natural ventilation from scratch, the use of sewer pipes is quite possible.

But if you need to add sewage pipes to the existing ventilation, it certainly will not work. The dimensions of products and connecting elements will be very different, it will not be possible to assemble such a system.

Many people think that plastic sewer pipes secrete toxic substances. Therefore, for their own soothing, it is better to install such products for exhaust ventilation.

Harmful fumes, if any, will be removed from the premises. It is not necessary to speak about the appearance of sewage products.

PVC pipes for ventilation look more beautiful, they will harmoniously approach any interior.

A large number of housewives seeks to install a hood in their kitchen. The device provides clean air in the room, and the ventilation pipe for the hood harmoniously fits into the interior of the modern kitchen. The kitchen hood protects from the effects of fats and combustion products not only the human body, but also furniture, walls, windows.

Hood classification

Currently, all kitchen hoods can be classified by:

- method of mounting the exhaust structure;

- according to the basic principle of the extraction.

Types of hoods differing in the manner of installation

Depending on the method of installation, the following are distinguished:

- Suspended or ceiling hoods. Such devices are mounted on the ceiling, wall or cabinet. Installing the hood over the stove.

- Built-in hoods. Mounted inside the cabinet or special box. Outside, you can see only the part of the bottom of the device and the console for its control.

- Desktop. Most often used in public catering establishments and are an integral part of the installed kitchen equipment.

Types of hoods differing in principle of operation

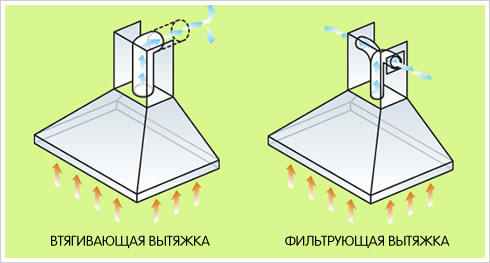

According to the principle of operation, all hoods can be divided into:

- Filtering devices. Purification of air occurs due to its passage through the filter. The most commonly used carbon filters, for the purity of which you have to constantly monitor. Such equipment is suitable for a small kitchen, where most food is not cooked, but simply warmed up.

- Retractors. The exhaust ventilation pipe of such equipment removes harmful substances directly into the ventilation duct provided for by the building structure or specially equipped for installation of the hood.

For home cooking the most popular are pulling hanging or recessed hoods.

Hood and duct selection

When selecting the necessary device, you should pay attention to several factors:

- power output;

- dimensions of the hood;

- selection of necessary air ducts;

- kitchen Design.

The minimum power of the device is calculated as a tenfold volume of the kitchen. For example, if the kitchen settings are 3 * 4 m, and the ceiling height is 2 m, then the room volume will be 24 m³. For such a kitchen, the minimum output is 240 m³ / h.

Specialists in the field of selection and installation of kitchen hoods recommend buying a device with a small margin of performance.

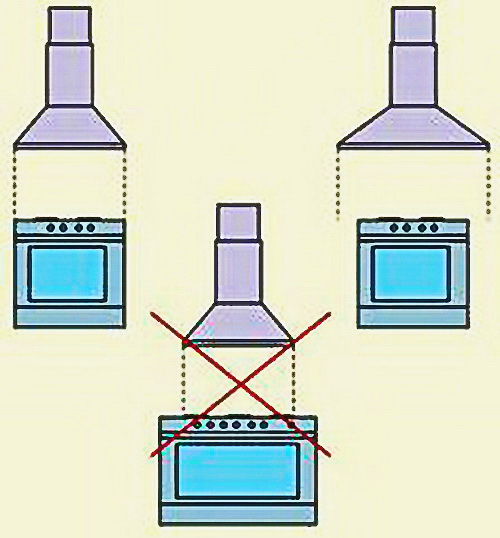

The size of the exhaust device must correspond to the dimensions of the surface of the gas cooker. If you do not comply with this rule, then some of the harmful substances and odors released during cooking will not enter the ventilation system and the extract will be useless.

Ducts for exhaust ventilation can be:

- Made of plastic. Such material is not corroded, easy enough, easy to install, not afraid of large changes in ambient temperature and exposure to harmful chemical compounds. Moreover, they do not have a negative effect on the human body.

- Made of aluminum corrugated pipe. The corrugated pipe for drawing has the main advantage - the complete absence of sound, which appears when powerful air flows through the duct. In addition, the shape of such a pipe can easily be changed by the parameters of the output from the hood extraction. The only significant drawback is that the corrugated ventilation pipe has a non-aesthetic appearance, but it can always be hidden in a box.

The choice of a pipe for extracting completely depends on the desire of the consumer.

Another important factor in choosing kitchen exhaust ventilation is the design of the previously equipped kitchen. Extraction should not stand out from the general picture, but harmoniously fit in and complement the existing appearance of the room. Manufacturers produce a large range of kitchen hoods, so the problem of aesthetics and harmony is completely solved.

Mounting the hood

Before you start the process of installing the hood, you must prepare all the components of the system and the necessary tools. For the ventilation system you will need:

- the exhaust device, selected at will and parameters;

- brackets for fixing the hood;

- pre-selected exhaust pipe for ventilation;

- clamps for fixing the air duct;

- the ventilation grille, which is intended for closing

the ventilation shaft and facilitating the connection of the air duct to it;

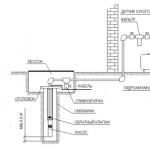

- a check valve mounted in an existing ventilation shaft to ensure the return of polluted air and unpleasant odors.

Instruments may require:

- perforator for attaching the hood to the wall;

- screwdriver for the assembly of the structure;

- roulette for accurate measurements;

- pencil for marking;

- sharp knife;

- hacksaw or electric jig saw;

- level.

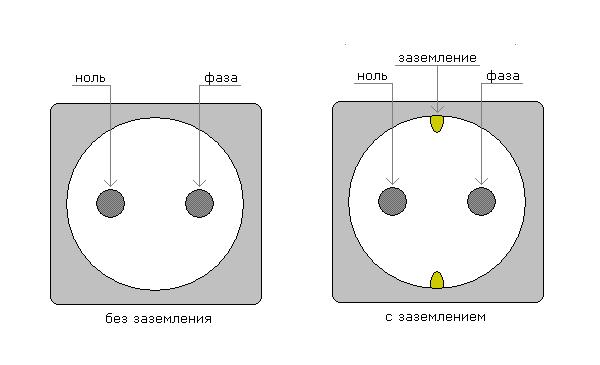

Ensuring the electrical safety of the device

Kitchen exhaust hood refers to appliances with increased danger. First of all, this is due to the location of the device. In the kitchen, water vapor is constantly accumulating, and fats from cooking get on the electrical equipment. These factors can cause an unintentional electric shock.

To prevent this from happening, and human security was at a high level, the kitchen hood is connected using grounding.

In new buildings, the function of grounding electrical equipment is already present. It is sufficient to install a grounded outlet next to the hood.

In older homes, you will have to connect the ground yourself or by using electricians. To connect the device yourself:

- In the electrical shield, located, as a rule, in the stairwell, find a deaf neutral. It is a walled metal pipe or a special tire with a built-in pin attachment.

- Accurately (voltage 220V) connect to the pin an electric wire with a minimum cross-section of 2.5 mm².

- Tighten securely with the control nut.

- Pass the wire through the apartment to the kitchen hood. For aesthetic clarity, you can use channels in the skirting boards or cable channels.

- Connect the hood to the other end of the cable through a 6.3A machine.

If you can not figure out how to connect the device to the ground, you can contact the specialists for assistance. Voltage in 220 V is dangerous for human life!

Installation of built-in hoods

To assemble the built-in hood alone, you must take the following steps:

- At the first stage, prepare the cabinet for fixing the hood. Such an adaptation can be purchased at the store or made independently. The cabinet should consist of the top and side walls. The dimensions of the structure must fully correspond to the dimensions of the hood.

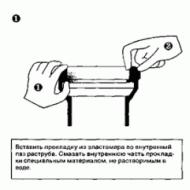

- In the upper panel of the cabinet, using a jig saw or a hacksaw, an opening is made for the duct, in which the adapter ring is fixed.

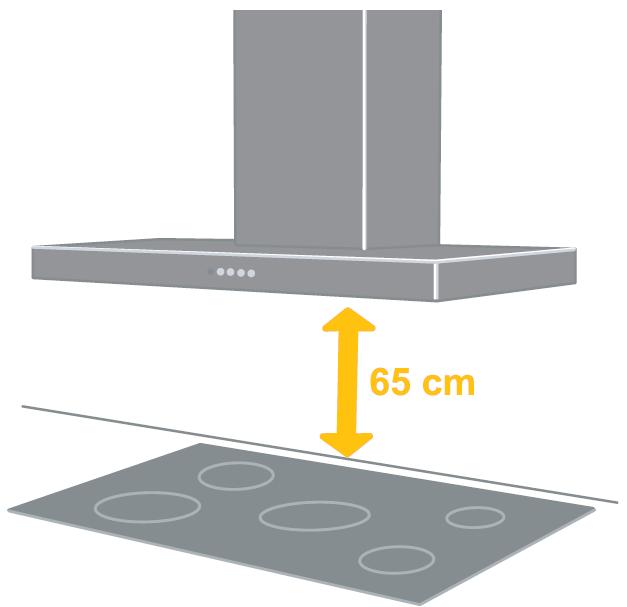

- Using the brackets, the cabinet is attached to the wall in the right place. The height of the hood above the gas stove should be as specified in the instructions. Usually this figure is equal to 65 cm if an extract is installed above the gas stove, and it can be varied if an electric stove is used.

- The hood panel is fixed to the manufactured cabinet. The connection points must be reliable. This will help to get rid of vibration and excessive noise when the device works.

- In the place protected from moisture, a power outlet is installed. This equipment is necessarily grounded. To do this, you can use either a special outlet or an additional wire for autonomous grounding. The power cord of the hood is connected to the outlet.

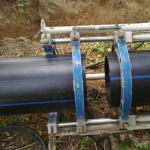

- At the last stage, pipes for the kitchen hood are mounted. One end of the duct connects to the hood and the other to the ventilation system. The connection is equipped with clamps and a ventilation grill.

For the correct operation of the cooker hood, it is necessary to observe the distance between the cooker and the device and securely connect all the elements of the system.

Mounting the hood

Unlike the built-in hood, mounting the attachments is somewhat easier. This design of the hood does not require the manufacture of a special locker. To mount the hinged kitchen hood alone, the following steps must be taken:

- On the wall at the desired level, a marking for mounting the hood anchors is applied.

- A separate socket with grounding is arranged next to the intended fixing point.

- The exhaust device is mounted on the prepared brackets.

- A corrugated pipe for ventilation is screwed to the exhaust outlet of the hood.

- The second end of the pipe is mounted in an existing vent by using a special one and a grille.

- To get a more aesthetic look, the ventilation pipe in the kitchen is fixed with brackets or clamps all the way.

When installing the duct, remember the important rule: every bending of the pipe reduces the productivity of the hood by an average of 10%. This means that if possible, the vent pipe must be straight.

Decorative work

Many people do not like the look of large pipes in the kitchen, and they are wondering how to hide the pipe from the hood. There are several ways to improve the airway:

- Do it. The simplest solution to the problem. The box can be painted in the main color of the kitchen interior. Mount it in various fixtures or LED strips.

- If the extractor is installed before the finishing works in the room, the main part of the ventilation pipes can be hidden under the construction of any type of suspended ceiling.

- The plastic ventilation duct for hood can be retrofitted to an additional shelf or to something else.

Decorative decoration of air pipes depends on the desire and imagination of the consumer.

If you correctly select and mount the hood in the kitchen, you can get rid of excessive accumulation of water vapor and unpleasant odors.