Scheme of high-pressure kercher. Kircher mini-wash: reviews about the car wash and a review of devices.

Today, we no longer need the strength and time to fight with the mud that has stuck and the dust hiding in the nooks, because every year new models appear on the market high pressure washers. These devices are used for washing windows, cars, walls and doors of houses, mangal and other items that are difficult to clean with a rag or brush. Strong pressure of water is much more effective in coping with this task and saves money spent on washing the car in the service, while water consumption is also minimal. Therefore, to have in your arsenal such a sink is useful for everyone.

The companies leading in the production of high pressure washers are the German firms Bosch, Karcher (hence the second name for the kerkher sink) and Elitech. The average price of these washers on the market starts from 10,000 rubles. Inexpensive car washes can not be used for more than one car a day, and the possibilities of the most expensive models are limited to seven cars.

Washing device

The main component of the sink (or kerher) is the engine, which creates the necessary pressure of water. Suitable pump or motor (do not necessarily buy a new one, take it from an old car), the motor is built into the body of the sink and must be connected to the power source. For the body of the sink (body), choose a durable material, thick plastic or metal. Even if you get a wear-resistant body, it's best not to use the sink for more than three hours in a row. This will remove the sink in a short time.

Hose nozzles are produced to facilitate the cleaning process - brushes of different rigidity, soft rollers, standard sprayers. If you buy a pair of baits, you can expand the functions of your washing, using it as an automatic mop or steam cleaner (you need to supply the sink with a heater).

Internal pressure

The higher the pressure inside the housing, the stronger the water jet hitting the hose, which means that the dirt lags behind more easily. Pressure set carefully, because water can simply break the fragile detail of the car or glass, leave dents. Manufacturers set a pressure of 150-170 bar, but to clean the car enough and 100 bars.

If the contamination can not be cleaned with a stream of water, get a special nozzle on the hose, turbo-cutter. It will help to clean tires, disks, remove dirt accumulated in the cracks. Use a mini-sink can be both outside and inside the salon. If you use a turbo mill, you will need a pressure of 160 bar.

Electropump pump

Before you buy and use the pump when designing a sink, read how to properly select this device.

The material of the pump determines wear resistance. An unfortunate option is a plastic pump, this one will soon fail if you use it more than 20 minutes at a time. Expensive, but reliable pumps are made of brass, because it does not lend itself to corrosion. These pumps are rarely found in purchased car washes.

How to use a mini-wash

To wash worked regularly, follow these recommendations.

- Be sure to check the operation of the washing before starting operation, it will save your time and health.

- The filter installed on the car wash is cleaned and replaced after each use.

- If the sink uses electricity in operation, and the source is unstable, provide it with a rechargeable battery.

- Do not let the children use the sink.

- If repair is necessary - do not delay with its carrying out. Replace the failed components of the sink.

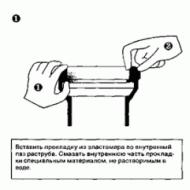

- Update the device gaskets.

- Protect the sink from temperature changes.

How to make a kerkher yourself

Although car washes and achieved widespread use, their price is great. So, if you want to do the washing yourself, you will need:

- canister;

- irrigation hose with gun;

- pump;

- choke;

- a cover for the canister;

- tubeless wheel fungus;

- rubber gasket;

- coupling.

These are the components of the future car wash. Materials that come in handyin the manufacturing process:

- drill;

- sealant.

First step. Choice of components.

The necessary volume of the canister depends on you and the purposes for which you will apply a car wash: for a car there will be enough five-liter canister. Drivers carry a car wash in the luggage, and therefore choose the body both in volume and in dimensions.

The irrigation hose must be strong and flexible, it must not be twisted or cracked. Hoses with a nylon braid are considered to be strong Hose, consisting of several layers, is more reliable. Do not skimp on this component. The only requirement is for the pistol: it must hold tightly to the hose.

The pump can be foot or automatic. The high power of this pump will not come in handy, so do not buy expensive. Use an automatic pump is much more convenient than a foot pump, because you do not have to constantly drag the pump from place to place and do extra work with your foot. However, the decisive role is played by the cost of the pump, the automatic is three times more expensive.

A coupling and a coupling you choose at your discretion, the main thing is that they are in close contact with each other. It is more preferable to purchase both the fitting and the coupling from one material (plastic or metal).

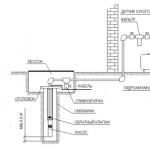

Second phase. Preparation of the canister.

In the canister, drill a hole suitable for the size of your coupling. In this hole, insert the coupling with a screwed fitting. Secure the structure with a sealant so that the coupling does not jump out during operation, and the pressure remains in the canister.

The third stage. Collection of the lid.

The lid needs a solid, hard and suitable to the canister. To prevent air from escaping from the canister, fix the rubber gasket on the bottom of the cover. Then make a hole in it and insert a tubeless tire fungus into it.

The fourth stage. Collect the design. Additional functions.

Cover the canister with a lid tightly, connect the cord from the pump to the fungus, attach the free edge of the hose to the hole in the canister with a fitting. Homemade washing is ready. The principle of operation of such a washing is simple: with the help of a pump, air is pumped into the canister with water (the canister is not filled with water to the edges). Pressure build up to 0.3 bar or higher if your canister stands. Under the influence of pressure water jets from the gun when you press the handle.

If you use the sink and in the cold season, provide your sink with a special torch for heating the water. For these purposes, a larger canister will be required, it will lose mobility, but with the help of hot water the car is cleaned of strongly adhered dirt.

Provide a power source for washing. If the car wash works on fuel (gasoline or diesel fuel), then with the movement there will be no problems. When planning an electric sink, take care of a working and affordable source of electricity. In this case, you are unlikely to be able to freely transport the car wash from place to place, but you do not have to spend money on expensive fuel.

In advance, decide for what purposes you are using the sink. If to clean the windows of the house or the wheels of the car, then you will like a compact, mobile washing on wheels and with a long hose. If you use a sink on a production scale, you will not need its ability to move, so it is better to design a stationary sink. It is connected directly to the water supply. If there is a need, adjust the water supply for saving.

If you can save on water consumption, you can not buy components for washing. To wash the object did not become dirty, get special filters. Do not need an expensive filter that cleans the water to a drinking state. The filter is necessary for water purification at least from litter, which will remove the sink from damage.

On the design of high pressure washers, you can even earn by opening a car wash. The main thing is that the sink you made works. Using a sink, you can clean bicycles, mopeds, cars, freight vehicles and their components.

How to make kerkher, working from the cigarette lighter

This washing design does not require cost. The following is an instruction for creating a more complex model:

Us you will need:

- motor windscreen washer;

- irrigation hose with gun;

- cigarette lighter (power supply motor), plug cigarette lighter;

- two hoses of 3 meters in length, one hose should fit freely into the other;

- corrugated hose with a diameter of 25-30 millimeters;

- switch;

- m8 bolt, washer and nut;

- two plastic cans (10 liters capacity);

- 6 screws;

- a two-wire electric wire 5-7 meters long;

- plastic sleeve;

- power cable;

- a car wash brush.

Additional materials:

- sealant;

- drill.

First step. Creating a hose.

Make a small hole in the bottom of one of the canisters. Inside the thick hose (with a diameter of 10 millimeters or more), place a thinner hose (up to 6 millimeters) and a two-wire wire. Then the hoses we have fastened are inserted a canister hole. A plastic sleeve is inserted into the free end of the hose. Next, a thin hose is attached to the washer motor, the wires are also attached to the motor.

Second phase. Creating a can with a double bottom.

The second canister is cut approximately in the middle to subsequently make the second bottom out of it with the shuttle. The motor is fixed on the second day of the canister, for this purpose a self-made yoke is used, which can be made from the remains of a cut canister. To do this, we need a bolt M8 and a bit of sealant.

Wires are also fixed using self-tapping screws and sealant. Then they combine, again, using self-tapping screws, the body of the structure: the second bottom and the hinged cover.

The third stage. Completion.

Using the power cord, the wires are connected to the cigarette lighter. The hole for the button is made in the brush, the switch is fixed. The brush itself sits on the edge of the hose with a plastic sleeve. Use in your work the attached diagrams to better understand the text.

High pressure self-cleaning41 photo:

The principle of operation of the Karcher Full Control series

Cleaning agent Karcher

A cleaning agent is necessary for easy removal of dirt from any surface.

High pressure outlet

Under high pressure, the flow of water enters from the output hose to the pistol of high pressure, and from the gun to the surface being treated. I would like to remind you that in the new Full Control mini-model series on the pistols there are touch-sensitive operation mode switches, which greatly simplifies the operation of the mini-wash.

Piston (Engineer)

In the injector, pressurized water is mixed with Kercher detergent and enters the outlet hose.

Pistons and valves

The system consists of three pistons each of whichworks translationally,creating pressure in the pump.After that, the outputflow of waterunder high pressure.

Piston

The piston is lowered by translational movement downwards thereby sucking in the liquid and interacts withsuction valve , which creates pressure in the piston chamber, releasing a powerful jet of water under high pressure into the injector.

Pressure Relief Valve

The pressure relief valve is needed to adjust and maintain the system's uniform operation.

Bearings

Bearings translate the energy of engine rotation into translational mechanical operation of pistons and valves.

Water cooling system

The water cooling system used in Kerher devices protects the motor from overheating, which ensures its reliable and durable operation. First of all, Kercher is German quality and reliability.

Flow of water

Input element for supplying water to the mini-wash. Typically, the supply of liquid is done by connecting the garden hose, but if there is no tap or other source of fluid under pressure, in the Kercher mini-masters of the Full Control series there is the possibility of collecting liquid from a canister, bucket, or other container.

Electric motor

An electric motor is an element of a mini-bowl that drives a Kircher mini-wash pump, by converting eleteric energy into a mechanical one.

The principle of the Karcher mini-wash

We tried the water. We tried soap. Tried to rub and scrape off. We tried strong chemicals that do not meet the stated requirements. So when will it be clean?

Discover the Karher high-pressure washers! At present it is difficult to find a person who would not know about Kercher mini-washing. And many of them have already tried this useful invention. Super-powerful hose, powerful jet of water under pressure approximately 100-200 times higher than the air pressure around us. Now everything shines: courtyards, cars, country furniture, barbecue and everything that can be cleaned of pollution. Let's now take a closer look at how they work!

Why does a jet of pressure make things cleaner?

Let's start with the fact that the water itself copes well with pollution, and there is a strong scientific reason for this. Its molecules have a small electrical polarity (one end is positively charged and the other is negative), so they tend to be attracted to things in themselves.

Detergents (soap, chemicals) help water to do its work even better, destroying the molecules of oil and fat. But some types of pollution simply do not budge, no matter how hard you try. Then the high-pressure apparatus will come to the rescue. He uses a narrow jet, under high pressure of hot or cold water, to destroy the structure of the mud. As the water moves quickly, it hits a dirty surface with high kinetic energy, acting on dirt and dust, like thousands of tiny hammer blows.

Water destroys dirt, but this does not damage the hardest surfaces. However, it is usually always recommended to check the jet in a safe area. That's why Karcher has released a new series of Mini Control Full Control with a pressure regulator depending on the surface. On the handle there are touch buttons with a surface designation, so that your surfaces are now safe!

Components of the Kerher high-pressure apparatus.

A high-pressure device is arranged in a simpler way than you imagine when you hear its name. It is a water pump that is powered by an electric motor. The machine takes water from a conventional tap, the pump accelerates the water under high pressure, and then injects it from the hose at a speed, through a manual spray gun. You can adjust various accessories to the end of the hose to clean various things.

Mini-washing machines are high-pressure devices, which ensure high-quality and quick cleaning of certain surfaces. It is worth noting that if you add detergents, the effectiveness of cleansing will be increased.

Mini-washing machines are used not only to wash the car, but also for furniture, the facades of the house. Thanks to the use of the unit, manual labor is automated, and water and cleaning agents are saved.

Small home mini-wash pressures from 12 to 160 bar, connect them to a normal outlet. You can bring water to the device from any accessible place, be it a water pipe or an ordinary tank.

How the device works

Perhaps, it does not happen easier, the heart of the mini-wash is an electric motor, it rotates the eccentric, and the plunger works from it.

Each plunger has two valves - the top and bottom respectively. Through the lower valve water enters the chambers, and through the upper valve, it is fed into the nebulizer.

The body of the device is a durable plastic capable of withstanding any mechanical impact. Nozzles and gun are made folding.

Unlike professional models, the pump unit is made of aluminum or plastic, due to this it is possible to reduce the cost price. But this implies one significant drawback of the mini-wash - a short life. Experts advise not to use the mini-wash more than two hours a day.

Bookmark this site

- Selection

- Installation

- Finish

- Repairs

- Installation

- Device

- Cleaning

How to make a high pressure washer

- Choice of parts for cleaning

- Recommendations for the construction of a high pressure washer

- Washing device

- Additional washing functions

- Step-by-step instruction for creating a sink

Over time, more and more widespread in the domestic markets were high-pressure washers, mainly used for cleaning cars. Using a similar device, it is possible to perform a washing of both the body part, and the bottom and the engine compartment. Undoubted advantage of this device is that to eliminate dirt from the surface of the car using a precisely directed jet without the use of a powerful water pump. A very advantageous idea is to clean the high pressure with your own hands, which allows you to save considerably money spent on the periodic washing of the machine. If you take into account domestic weather conditions, when at any time of the year on the roads there is dirt in any of the aggregate states, then such a washing will pay off very quickly.

The easiest way to do the washing yourself is to use an air compressor.

Basic principles of creating a sink

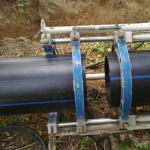

The main functional element of the sink is a pump that meets a number of requirements. So, it should show high functional performance for one unit of time and operate in normal mode at a pressure of about 100-200 bar. Many plunger pumps equipped with an electric drive have such characteristics. Choosing a pump for your future washing, special attention should be paid to the material that became the basis for its working part. The best option, if for the pistons of the pump will be used ceramics or strong metal. The best option for making the cylinder head is brass. Sturdy composite parts guarantee a long service life.

The most profitable is the purchase of a pump with a working capacity of about fifteen liters per minute and a pressure of up to two hundred bar.

It turns out that such a pump in normal operation will operate at 80-90% of its power limit.

Back to contents

Choice of parts for cleaning

When choosing an electric motor, one should pay attention to models that have a power supply of about 220 or 308 volts. In the event that the high-pressure washer is used at home, it is advisable to use a single-phase 220 volt connection, as it does not entail additional costs and meets all safety requirements. To ensure optimum start-up of certain motors it is desirable to use additional condenser units. So, the performance of the pump is directly dependent on the number of engine revolutions: the higher their frequency, the greater the productivity.

But it is worth considering that work in this mode can negatively affect its resources. Do not give preference to too high-speed models. The maximum permissible rotational frequency in this case is up to two thousand revolutions with a power of two or three kilowatts.

A high-pressure sink of a certain design allows to provide the necessary pump capacity when using a single-stage gearbox operating with a V-belt drive. From the parameters of the pulleys (slave and master) their gear ratio depends. No less important role in the activity of gearboxes is played out by the characteristics of the distance between the axes of rotation.

To ensure the fixation of the pump and the engine, a clutch is usually used. The most suitable option is a soft clutch, which can compensate for the minimum axial mismatch of the shafts and act as a safety element in case the gearbox or pump jams.

A very important structural element of any washer is a water storage tank. In order to ensure maximum pump performance, it is necessary to use a certain volume of liquid. To do this, it is possible to use a special tank for a liquid that can make up the water from the water supply system. It is obligatory to perform the installation of the filter element (it can be an ordinary small network) on the outlet from the tank, intended for cleaning the liquid from dirt particles and preventing the blockages from entering the pump. To enhance the detergent effect, a special or usual detergent can be added to the liquid.

Car wash, made by hand, should have a pump capacity control in its design. Usually this device is connected to an automatic unloading valve, able in a critical situation to redirect the liquid back to the tank, so that no harmful load is created on the pump.

In order to fix all the structural elements of the sink, use a special frame. For its construction, hollow bent pipes can be used. To ensure the convenience of its use, it is possible to fix a pair of small support wheels in its lower part and make an emphasis to impart a stability structure during use. One of the ends of the frame can be equipped with a special handle, designed to transport the sink through the yard or garage.

The main constructive element of self-made washers is a water tank. In order to maximize the pump's performance, you need to use a certain amount of fluid.

One of the most important elements, which consists of a sink made by own hands, are high pressure sleeves. The standard not too thick reinforced rubber or plastic hose can act as a sleeve. It should be borne in mind that all constructive hose connections must be made in compliance with the tightness conditions, on the one hand, and not be afraid of corrosion and easy to disassemble, on the other. To attach fasteners, you can use fittings or threaded bushings made of hard aluminum alloys or brass. For this purpose installation of bayonets is possible.

When constructing a sink with your own hands, you must also pick up a gun equipped with an injector. Due to its shape, an imitation of the working jet shape is obtained. Actually, it looks like a pistol used on automobile refuellings. In order to start feeding water from the nozzle, you should press the handle. This is an undoubted plus, since it saves a lot of water: the liquid is supplied only when it is needed, by pressing the handle of the gun. It is quite problematic to run the shut-off valve with your own hands, the simplest and most reliable option is to purchase a finished tip.

Back to contents

The high pressure pump from the car washer is perfect as a car wash compressor.

Performing high pressure, you need to take care of creating a grounding. For this purpose, a three-core flexible wire equipped with double insulation is often used and a plug supplemented with a ground terminal. It should be borne in mind that the power outlet also needs reliable grounding by means of a circuit.

Periodically it is necessary to inspect all connections and fasteners and to tighten them if necessary. Regularly clean the filter element of the tank of accumulated debris.

It is undesirable to too often use a jet of water with a strong head - this causes excessive loading of the discharge pump and causes damage to the paint and varnish coating of the car. It is recommended to use a pressure capable of contactlessly rid the machine of the main layer of dirt on the surface to be treated, and with the help of a brush, manually remove the remaining dirt.

Back to contents

How does high pressure wash work?

Thanks to devices operating at a high pressure within the range of 120-150 bar, it is possible to remove dirt from almost any surface. It should be prepared for the fact that a small layer of plaque will still remain after such treatment.

Any washing must have a device that regulates the nozzle. When adjusting the position of the nozzle, it is possible to change the pressure or shape of the jet. The nozzle can be equipped with foam generators and additional mud mills.

If desired, you can design with your own hands a sink that can be fed not only directly from the water pipe, but also from a special reservoir - for example, a barrel with water. To improve the pressure in the sink, you can put the barrel on a small elevation.

In the event of a power outage or the use of a sink away from the outlets, it is possible to complete the device not only with a water tank, but also with a powerful battery.

The undoubted advantage of sinks of such a plan is a great saving of water, in contrast to manual washing.

Back to contents

Washing device

Inside the high-pressure sink, an engine must be located, provoking the rotation and opening of the remaining parts - valve, washer or spray. The result of his work is the unwinding of the washer and the movement of water through the sprayer according to the forward-return path, resulting in water and enters the valve of the sprayer. The result of the action of many mechanisms is the formation of a powerful head and water supply.

The body for cleaning it is desirable to choose from shockproof plastic. The same requirements apply to the hose that connects to the atomizer, since it will have to interact with a strong water head.

Regardless of how strong the materials from which the sink is made, it is highly discouraged to use it more than two hours in a row. Too long a cycle of work can lead to rapid deterioration of the component parts and several times reduce the life of the device.

If you complete the sink with additional nozzles, it can perform the functions of household appliances. When using additional nozzles, the washing can be used both for washing the car, and for cleaning the roofs, facades and floors.

Back to contents

Basic high pressure washers

A sink made by hand consists of the following elements:

- a durable, wear-resistant housing;

- engine running on gasoline or from electricity;

- a pump operating at high pressure;

- containers for water and detergents;

- additional attachments;

- filters for water;

- hoses.

The principle of homemade washing is extremely simple. From the water pipe or special container after connection, the water enters the washing container and is pumped through the pump. In the maximum load mode, the washing works at a pressure of about 160 bar. For comparison, a water jet from a conventional tap is fed under a pressure of five bars.

The next step is to feed water through a hose to the gun with the nozzle. It is desirable to equip the gun with a special nozzle that allows changing the nature of the water flow - from the concentrated jet to spraying. The nature of the water supply should be determined, based on how the surface will be cleaned. For example, to cover a large area (veranda platform or car body), the best option is a fan jet. In order to remove fragments of stubborn dirt, it is desirable to use a pointwise water supply option.

In the role of additions can make a nozzle with a swivel nozzle, a rotating brush and much more. The main advantage of using attachments is contactless cleaning of the surface, which significantly reduces the risk of damage to the paintwork of the car body or the decorative surface of the facade tile.

When selecting parts for a sink, do not chase the maximum power. Sink used at home can function normally at an operating pressure of 100 bar. Especially for a person who has not faced such a technique before, it will be problematic to manage a car wash that works under high pressure.

The climatic conditions of most of the territory of Russia stipulate the need for frequent car washing, especially in the spring and autumn seasons. In this regard, the actual question of the availability of own washing equipment. In this article, the minicomputers of the producer Karcher are considered.

Features

The presence of washing equipment allows you to wash at any convenient time. The cost of the device will be compensated in case of prolonged use. Since the washing will be done by yourself, this will require some effort from the user, but this process is very simple and quick to implement.

In addition, in this case, there is no need to move until washing and waiting, so that in most cases, wash the car with your own hands even faster than in a car wash.

Main Features and Options

When choosing a mini-wash for the car you need to take into account its technical parameters, which are discussed below.

- Performance. This term is understood as the volume of water pumped by the pump per unit time. This characteristic determines the force of the head.

- Pressure. Quantitative characteristics of the effect of water flow on the surface. A lot of pressure is required to clean heavily soiled surfaces, such as the bottom of the car. To do this, consider devices with a pressure of more than 100 bar, which allow you to wash the body of most types of contaminants.

- The presence of a filter. This device serves to protect the pump from damage by microparticles that are contained in water, especially rigid.

- Water intake. A car wash can consume water from a water pipe or from a tank, which is determined by the ability of the device to create a water head. Mini-moths that do not have it, are able to take water only from the water supply, because only the water can provide water under pressure. As you know, such devices are characterized by low mobility. In the process of working from the water pipe, you can go only at a distance corresponding to the length of the hose mini-wash.

- Presence of water heating. This is important for the use of a mini-wash in the cold period, since washing with cold water under such conditions can lead to damage to the paintwork.

- Total Stop. This system automatically turns off the electric motor of the mini-wash when you release the handle of the gun and serves to save water. The principle of the automatic shutdown system is that after releasing the trigger of the gun, an overpressure is generated. Under its influence, the bypass valve stem presses the switch. This leads to a power failure. After clicking on the lever, events occur in the reverse order.

- Based on the above parameters, the mini-bowls are classified into the following classes: primary, intermediate, higher and higher (or extra). It should be borne in mind that some manufacturers are developing their own, usually broader classifications of mini-washers.

Pump pump materials

Their strength determines the longevity of the device, this is because the head of the pump is considered one of the most vulnerable elements of the mini-wash. This is due to the susceptibility of this part to the operation of the device to the maximum water pressure. Plastic heads have the lowest strength and, therefore, the cost. However, their strength is predictable - the limit is up to an hour of continuous use. Longer use of the device leads to the destruction of plastic heads.

It should be borne in mind that in the event of a breakdown, the cost of repairs will be comparable to the price of a new mini-wash, so saving is therefore inappropriate. Metal heads that are made of brass or silumin are more durable and costly. At the same time, silumin heads are somewhat inferior to brass ones in strength, so the former are used in household mini-washings, and the latter - in professional models.

The design of the mini-wash

The considered models of compact car washes are simple. Their structure is represented by the following elements.

The electric motor creates energy for the functioning of the mini-wash. Most models of these devices are equipped with electric motors from 1.4 to 3 kW. The company Karcher equips its mini-washing machines with water cooling. These systems, providing effective cooling, protect the engine from overheating and increase the time of continuous operation. Due to this, such engines provide high-performance mikro-masks equipped with them and a long service life.

The pump supplies water to the appliance. As it was mentioned, household models of mini-washhouses are equipped with plastic or aluminum pump blocks with valves of the same materials. This causes a relatively low cost of such devices, but imposes some restrictions on their functioning. First of all, they apply to the time of continuous work. For minimoek of this type it is about an hour. For each device, the exact value of this parameter is specified in the instruction. Professional models are equipped with pumping blocks of stainless steel or brass. Such mini-washings are designed for continuous operation on the continuation of several shifts.

A flexible hose connects the device to the nozzle. The smaller its diameter, the higher the water pressure. The nozzle ensures the spraying of water on the surface to be treated.

Additional equipment - this category includes some parts that increase the usability of the mini-wash and expand its functionality. They are represented by:

- nozzles;

- jet tubes;

- a drum for winding a hose;

- foam sprayers;

- brushes;

- regulating the pressure of pistols.

Principle of operation

The principle of functioning of the devices under consideration consists in supplying a jet of water under high pressure to the surface being treated. The pressure creates a synchronous motor. The rotating shaft of the motor drives the inclined washer in the form of an eccentric attached to it. The plungers in contact with the washer are reciprocating. In an electric motor, these parts perform the same function as the pistons in an internal combustion engine.

The principle of functioning is similar, but the difference is that water flows through the intake valve of the electric motor instead of the fuel mixture of the internal combustion engine. This occurs when the plunger moves to the lower point. When it moves upwards, an overpressure is created, and the exhaust valve opens.

Karcher mini-washing machines

In the assortment of the company in question, there are two classes of high-pressure mini-presses for cars: medium and extra. Medium-class devices have a sufficiently high performance to remove many types of contaminants, including medium and strong. The manufacturer specializes in high-end mini-washings as devices for cleaning large areas from particularly persistent contaminants.

In addition, the range of Karcher includes autonomous car washes, equipped with internal combustion engines. These devices are designed for use in the absence of access to the electrical network. Among the mini-classics of the middle class are the instruments of three subclasses: K3, K4, K5. Only the K7 devices belong to the higher class, and the stand-alone mini-mouses are represented by devices G.

Further discussed in more detail mini-washing machines, designed and suitable for cars. In the middle class, these include K3 Car, K4 Car, as well as all other modifications of subclasses K4 and K5. Car wash K3 Car is equipped with a set of devices for car washing. It is suitable for contact and non-contact cleaning. This device is equipped with a water filter.

Kercher K3

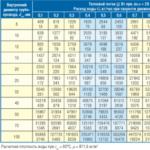

Specifications Karcher K3 Car:

- productivity - up to 380 l / h;

- power consumption - 1.6 kW;

- pressure - 20-120 bar / 2-12 MPa;

- productivity on the area - 25 sq.m / h;

- frequency - 50-60 Hz;

- the voltage is 220-240 V;

- dimensions (length x width x height) - 275 x 279 x 803 mm;

- weight without accessories - 5.8 kg.

The K3 Car includes the following accessories: 6 m high pressure hose, mud milling cutter, Vario Power nozzle, Quick Connect system, car kit (0.3 l foam nozzle, brush, car shampoo), adapter for garden hose A3 / 4 inch , water purification filter.

Customer feedback indicates the high quality of the assembly, the compact size of the device and functional accessories. At the same time, they note the low reliability of the pump and insufficiently high power, especially for cleaning persistent contaminants or heavily soiled areas, for example, the bottom.

Kercher K4

The car wash K4 Car is slightly superior in performance to the Karcher model discussed above.

Specifications Karcher K4 Car:

- productivity - up to 420 l / h;

- pressure - 20-130 bar / 2-13 MPa;

- the voltage is 230 V;

- productivity on the area - 30 sq.m / h;

- power - 1.8 kW;

- frequency - 50 Hz;

- inlet temperature - up to 40 ° C;

- dimensions - 300 x 394 x 876 mm;

- weight without accessories - 11.8 kg.

K4 Car includes, in addition to accessories included in the K3 Car, a system for cleaning products Plug 'n' Clean and a telescopic handle.

Customer feedback indicates an acceptable price and high quality assembly. As shortcomings, note a short high-pressure hose. Also, some users seem uncomfortable with the detergent supply system and insufficient power.

Other devices of the subclass K4 differ from those considered in the main bundle, which causes some subtlety of application. The design of the case from other models of the subclass is characterized by mini-K4 Silent and K4 Compact.

Kercher K5

Devices of the subclass K5 are the most productive in the middle class of Karcher mini-washers.

Specifications Karcher K5:

- productivity - up to 500 l / h;

- frequency - 50 Hz;

- pressure - 20-145 bar / 2-14.5 MPa;

- dimensions - 349 x 427 x 867 mm;

- inlet temperature - up to 40 ° C;

- power consumption - 2,1 kW;

- the voltage is 230 V;

- productivity on the area - 40 sq.m / h;

- weight without accessories - 13.3 kg.

The K5 car wash is equipped with a longer hose (8 m).

Users highly appreciate K5. They especially note the high power, sufficient to remove most of the dirt and clean even the bottom of the car, and versatility.

Kercher K7

K7 mini-washings, included in the upper class, represent the most powerful Karcher devices of this kind with electric motors.

Specifications Karcher K7 Compact:

- productivity - up to 600 l / h;

- frequency - 50 Hz;

- dimensions - 552 x 90 x 333 mm;

- power consumption - 3 kW;

- the voltage is 230 V;

- productivity on the area - 60 sq.m / h;

- weight without accessories - 17.1 kg.

This Kerber mini-washbasin has a 10 m high pressure hose.

Users appreciate the K7 Compact. Their testimonials indicate the quality, high power, pressure and performance, long hose. As a disadvantage, they note only the horizontal position, high water consumption, the lack of some accessories, fragile connections.

Kercher G

Class G mini-mouses equipped with internal combustion engines differ from the above-mentioned devices with self-contained electric motors.

Specifications Karcher G 7.10 M:

- productivity - up to 470 l / h;

- dimensions - 597 x 547 x 620 mm;

- pressure - 20-160 bar / 2-16 MPa;

- power - 5,5 kW;

- weight without accessories - 30.5 kg.