Ventilation in a private house from sewer pipes - justified saving on repairs. Exhaust pipe for ventilation in a private house: device and installation

Following the right decision, to arrange a ventilation system at home, the question arises of choosing the right material.

From what pipes for ventilation in a private house are made, what are the best to choose and what do you need to know about them.

There are only two main options. Channels for air are made of either metal or plastic. Consider their pros and cons.

The options are:

- Of black steel.

- Of galvanized steel.

- Stainless steel.

Looking ahead, you can immediately say that for small private buildings, metal ducts are not used often.

We perform a comparative analysis of metal and plastic pipes for ventilation.

Metal pipes are heavy, which means they are more difficult to mount. They are more difficult to connect.

The service life of steel is small (on the scale of building structures, which are theoretically erected for centuries). Steel is susceptible to corrosion. The zinc layer slows down this process, but does not completely cancel it. Weak points of galvanizing are joints. And even when rusting is just beginning, the pipes emit a characteristic smell, which is unpleasant in an apartment building.

Noticeably stands out against the background of previous versions of stainless steel. The service life is much higher, but the price is incommensurably higher than that of a plastic analog.

In addition, any metal pipes create an airflow resistance. This means that the owner will have to buy a ventilation system more powerful than for a plastic version.

Metal can not be called noise insulation material. Any sounds, fans, vibrations, etc., will echo throughout the ventilation shaft.

Metal pipes are resistant to high temperatures, corrosive environments and most importantly - of any shape and size (this explains their use in ventilation systems of large plants and enterprises).

But if you have a private house, and not a hot shop, then you are lucky that plastic was invented!

Plastic ducts

These ducts will serve for a long time. A very long time. They do not rot and do not rust at all. And if in other cases there is a risk of damaging brittle plastic during operation, then in ventilation structures, the pipes are hidden in the ceiling space, brick mines or in the walls of frame houses. That is, the opportunity to harm them is minimal.

In addition, plastic pipes are light, which is important when the construction hangs over people, and it is easier to transport and install.

In addition, plastic pipes are light, which is important when the construction hangs over people, and it is easier to transport and install.

Easily cut, which is also convenient when installing complex branches.

The technology of assembly and connection is the simplest.

Smooth surface inside - perfectly conducts the air, not inhibiting the flow.

Very slow clogging, cleaning is rarely required.

Sagging - no more than 4%.

The dimensions of the straight sections that are produced along the length range from 3 to 12 m. The cross section ranges from 16 to 1600 mm. Also available are all kinds of fittings, turns and adapters.

If we add the lowest cost here, it becomes clear why plastic pipes are the leaders of ventilation systems.

Dry air in the apartment does not contribute to the health of residents, and in winter this problem is relevant for many. In this article, we will look at the types of air humidifiers and try to understand which device is best for choosing at home.

Alternative pipes for ventilation installation

Ventilation in a private house from sewer pipes

Sewage is also made of plastic, but these pipes are several times cheaper than ventilation.

A reasonable question arises: can air ducts be made from them?

Opponents of the method usually give two arguments:

- Diameters do not match.

- This is a technical plastic, it emits harmful substances that will fall into the air of the room.

If to speak about the sizes, craftsmen find ways to adjust the various sizes by means of adapters or an insulating tape. This, of course, violates the flow aerodynamics. But if you still decide to do this, firstly, it is necessary to make the entire air duct from the sewer pipes from beginning to end, so that there are no steps. And, secondly, the transition from size to size must be carried out smoothly (use a tapering element).

The argument about harmful evaporation makes the sewage pipes suitable only for the exhaust ventilation branch. It is better not to install doubtful plastic on the inflow.

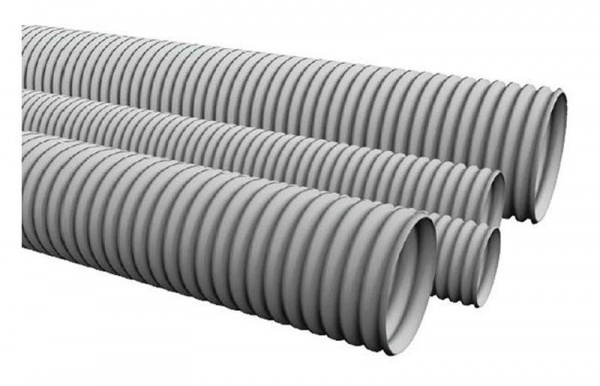

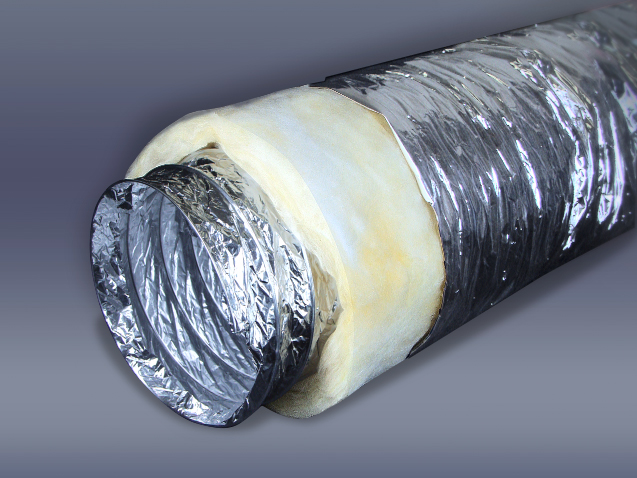

Flexible corrugation

For example:

For example:

- The ribbed surface brakes the flow much more than metal or, especially, plastic pipes. On a long stretch this is very noticeable.

- There are difficulties with fastening.

- When the flow is stably strong, vibration occurs in the corrugation, and this is detrimental to the joints and causes noise.

By the way, on the market it is practically impossible to find connecting elements for corrugated pipes. This is because manufacturers also understand that their products are not designed for use in long pipelines.

The corrugation can be aluminum and plastic. The aluminum version is prone to condensation and heavier. But they are used wherever there are high temperatures.

Aluminum corrugated air ducts can curl as you like, but you need to remember that too strong bends violate the movement of air.

Use corrugation is possible only in short complicated areas of ventilation, where the laying of a rigid duct would require the creation of a multitude of knees. Turnings in the system are extremely undesirable and, if you choose from two evils, then soft corrugation will make a smooth bend.

Advantages and disadvantages of using

So, if we sum up briefly, we get the following picture.

Metal ducts - more minuses:

- heavy;

- rough;

- more difficult to connect;

- noisy;

- accumulate static electricity;

- steel is susceptible to corrosion;

- stainless steel is very expensive.

- fireproof;

- are produced in large diameters and in any shape.

PVC air duct is an excellent option for the private sector:

- lungs;

- simply connect, mount and transport;

- good sound insulation;

- smooth surface;

- do not rust, long service life;

- inexpensive.

- when burning produce corrosive substances.

Corrugated segments are advisable to use in small areas where a smooth turn is required. Use the sewer pipes for the hood - it's up to everyone to decide on their own, but it's definitely not worth it on the supply branch.

Instead of concluding a few more points.

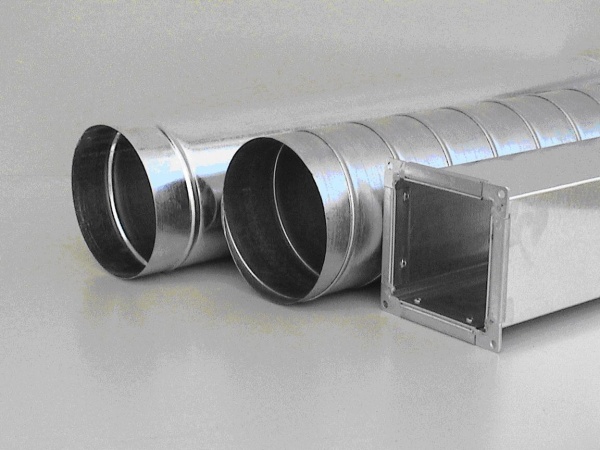

The shape of the air ducts can be oval, round or rectangular. Round and oval products can be spiral or straight.

The shape of the air ducts can be oval, round or rectangular. Round and oval products can be spiral or straight.

Spiral is more rigid, but the price is higher. They can be purchased if you need a long straight line.

Rectangular are easier to mount, they use the space more rationally, but they have less aerodynamics.

They are only stitches. Sites between the fastening elements can be 1-2 meters, if done more, the probability of sagging is high.

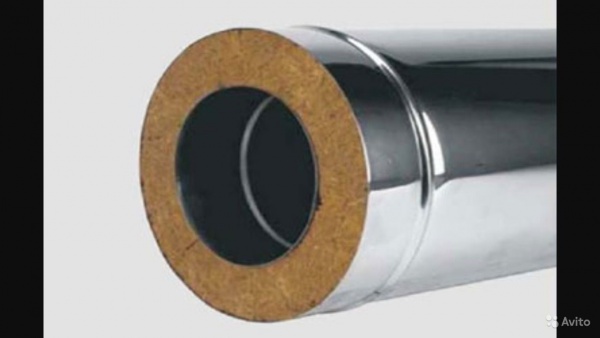

When passing through the air ducts of a cold stream, condensation forms on its outer surface. For this and other reasons, a mandatory condition is the insulation of the ventilation duct. There is an option to buy a heater separately and do additional work independently, and you can purchase a pre-insulated version of the pipes. This will save you from unnecessary trouble, although you will have to pay for it.

Ventilation in the bathroom should receive close attention, because too moist air leads to dampening of walls and ceiling, which further leads to the growth of mold. : advice on selection and installation read on our website.

On the criteria for selecting the hood in the kitchen read the link. Variants of designs, material of the device and cost.

Video on the topic

Ventilation from sewer pipes is a popular solution for a private home. What are its advantages over traditional ventilation from metal pipes, and what is it inferior to it? How to make it yourself?

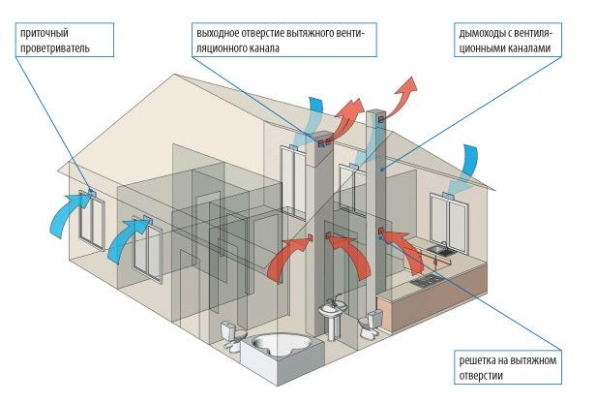

Principles of air circulation in living areas

The ventilation system is a complex of air ducts and channels through which contaminated air is removed from residential premises. In order for such a network to function normally, it must be properly designed and installed in accordance with modern standards, taking into account the individual characteristics of the internal premises and the rules for their operation.

The principle of natural ventilation is extremely simple - in rooms during their use, stagnant air is formed, the presence of which leads to the appearance of low pressure zones. From these zones oxygen tends to zones with high pressure, leaves the house through special ventilation channels and is replaced by fresh air. Circulation of air masses is continuous and for natural reasons, therefore, with proper design in homes, it is not necessary to install expensive artificial ventilation systems.

The efficiency of natural ventilation is affected by the number of air ducts, the total length of the ventilation ducts, the area of the pipe sections and other factors. But in general, the natural system is fairly simple. For its construction, it is enough to assemble the air duct, place its elements in all rooms and bring the ventilation ducts to the central riser. By its design, such a system is not much different from sewerage.

Why do you use sewer pipes for the communication device?

Of plastic pipes is created quite often. The popularity of such systems is explained by their simplicity and functionality - any owner, if desired, can plan and create a ventilation system for his home independently, without seeking help from professionals.

Before the advent of plastic pipes on the market, the natural exhaust ventilation system was built on the use of metal pipelines. The tin ventilation system was assembled by welding and sealed by fittings. In the process of operation, considerable investment was required to make changes to the design of such a system.

When the plastic pipe appeared on the market, the shortcomings of the tin ducts faced the owners especially sharply. Of course, plastic can not compete with metal products for resistance to temperature effects, reliability and durability, but PVC has its unique characteristics and advantages that made plastic pipes for ventilation in a private house the most popular technical solution.

PVC pipe for ventilation systems - the most important advantages and disadvantages

There are no legislative norms prohibiting the use in a ventilation pipeline of plastic products intended for the construction of sewerage systems. But before you start planning the installation of a new system of PVC, you need to understand the characteristics of such products, in their advantages over tin pipes and disadvantages.

To positive qualities of ventilation from plastic sewer pipes can be attributed:

- 1. Low cost. At the price of PVC pipes are much more profitable than tinning analogs.

- 2. Practicality. From plastic products, it is possible to assemble various ventilation systems according to functionality.

- 3. Easy installation. All the works on the installation of communication the owner can perform independently.

- 4. Anti-static. Plastic does not pass an electric current.

- 5. Antibacterial characteristics.

- 6. Plasticity. The plastic pipe can be bent as desired, in any direction.

But if you compare plastic products with specialized for the construction of ventilation systems metal, the sewage pipe will have the following drawbacks:

- 1. Strength. Plastic is much less reliable, durable and resistant to negative external influences than metal.

- 2. Low resistance to high temperatures. Sewer pipe is not intended for use in environments with an air temperature above +50 degrees.

- 3. Limited available mounting options. Pipes made of plastic are not recommended to be installed under the ceiling of a private house.

As a result, it is possible to build ventilation systems from sewer pipes that are less stable and durable than metal ones, and also not adapted for the transport of hot air. Because of this PVC products can not be used to build fire ventilation systems, as well as to create hoods in the kitchen above the work surfaces. Sometimes, the drawbacks of products include the fact that they are not designed for installation under ceilings and walls, because of this, the owners sometimes have difficulties with the acquisition of suitable fixtures.

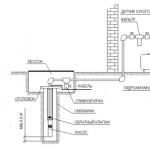

Stages of the construction of an accessible and functional air circulation system

For the device of ventilation in the house a scheme is needed. The drawing of the system can be ordered from specialists or made by hand. Designing of engineering systems is a complex and responsible task, on the quality of implementation of which will depend on the functionality, reliability and durability of ventilation. Doing this yourself is worth it only if you have the appropriate experience or a lot of free time, which can be spent on studying the norms of building ventilation systems, design rules and other important information.

In order for the new communication to meet the needs of future users at home, the owner should prepare a technical specification for the designers, specifying in it the requirements for the future network, its location in the house, the device of forced hoods in certain areas (bathroom, kitchen, bathroom).

When the communication project is ready, you can proceed to purchase the equipment and materials necessary for installation work. The device of the system requires: plastic pipes, fittings, special fasteners, etc. An exact list of required materials and consumables for performing assembly work can be found in the developed project. Experts deduce this information in a separate item of the project and often prescribe for each necessary product its approximate cost in the market.

When all the necessary materials are acquired, the owner will finally be able to start the construction of a new engineering system in the following stages:

- 1. Layout. On the walls and other surfaces, on which the pipes will be laid, mark the places of communication and the point of installation of the fasteners.

- 2. Mounting of fasteners. To the marked wall fixes the previously acquired fasteners, on which the ventilation pipes will be kept.

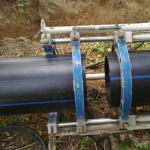

- 3. Collect the riser. A large ventilation pipe is assembled from large pipes, through which contaminated air will be removed from all rooms in the house.

- 4. Collection of air ducts. Of the smaller parts, pipelines are collected, through which the polluted air from the interior will be removed into the riser.

- 5. Installation of the riser and ducts. Mounted assembled pipelines are quite simple. To the installed fasteners fasten the products in such a way that their location exactly corresponds to the conditions of the project.

- 6. Connection of ventilation branches. All elements of the mounted system are connected to each other, creating a common engineering system.

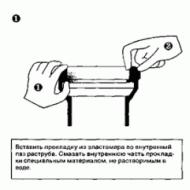

- 7. Sealing of joints. For ventilation, it is not necessary to seal individual pipes, if properly designed, the system will function properly without it. But the superfluous work on the sealing will not.

- 8. Installation of mechanical devices. Modern systems usually include not only pipes, but also mechanical products, for example, fans and valves. They provide the best inflow / exhaust of air from the premises, because they are very popular.

- 9. Installation of air dampers.

To ensure that ventilation not only provides a good microclimate in the interior, but also does not harm the attractiveness of the rooms, its planning and installation must be dealt with before the final finishing of the apartment house. Effectively hide the sewer pipes in the walls can be using plasterboard, which covers the surface with pipes, and then lined with suitable materials.

In all large buildings, it is necessary to ensure quality ventilation. To do this with the help of passive air circulation is almost impossible because of the large volume of rooms. Therefore, there is a need for a system of forced ventilation, an important component of which are the pipes. It is through them that air is circulated.

Ducts for the ventilation system must be light, as they are mounted under the ceiling. For heavy construction, powerful fasteners are required, which is not always possible. The pressure in the system is small, so the ventilation pipes do not need thick walls, which makes them easier.

The ventilation ducts are in direct contact with the air we breathe, and must consist of environmentally friendly material. It is also important to ensure the aseptic system to prevent the appearance of pathogenic bacteria in it.

Additional requirements are an aesthetic appearance (ideally the designs should not be visible under the ceiling and wall panels) and stability to the accumulation of static charge.

Types of pipes for ventilation systems

Over the years, metal pipes have been used in residential and industrial buildings. They are made of aluminum and steel alloys. Their advantages are:

- strength;

- durability;

- ecological compatibility;

- resistance to fire.

The disadvantage of metal is its propensity to corrosion. This problem is solved by galvanizing and using stainless alloys.

Another disadvantage is the large weight of the structure. It is eliminated by reducing the thickness of the walls of the ducts. As mentioned above, the ventilation system is not particularly demanding on strength. Another drawback - such pipes are able to accumulate static electricity. In the manufacture of metal ducts on the inner surface there is always a slight roughness, which increases the resistance to air flow and requires additional injection power.

The metal structures are noisy. Any alloy conducts sound well. The noise of a fan, an electric motor or air flow is often heard throughout the building. Sound is transmitted through ventilation ducts.

More recently, PVC pipes have appeared on the market. Their advantages are:

- ease;

- strength;

- low sound conductivity;

- absence of static electricity;

- resistance to corrosion.

Theoretically, plastic must serve forever. But compared to metal, it is distinguished by a higher fire hazard. Polyvinyl chloride does not burn, but at high temperatures it can release toxic substances that will immediately get into the air.

The PVC structures have an ideally smooth internal surface, which reduces the resistance to air flow and increases the throughput. Plastic pipes are better suited for installation in industrial plants where there is an aggressive environment, for example, air contains acid or alkali vapor. Metal under such conditions is susceptible to chemical corrosion, and polyvinyl chloride is an inert material. Also, plastic channels are easy and quick to install, do not require welding.

Below is a video instruction for the installation of plastic ducts

They are made of rigid or medium-grade polyvinyl chloride or polyurethane. It is possible to use multi-layer pressed paper impregnated with synthetic resin, but this material is afraid of water. It can not be used in rooms with high humidity.

Today almost all ventilation systems are assembled from PVC pipes. An exception is only some industrial enterprises, for example, metallurgical plants, where ventilation operates at high temperature. On such objects steel or aluminum air ducts are installed.

Important ! Plastic structures are prohibited for use if the temperature of the passing or surrounding air can exceed 80 degrees.

Also used are pipes made of magnetic inorganic compositions with the addition of glass fibers. They combine the advantages of plastic and metal structures - they are resistant to all types of corrosion, light, durable, do not burn and are not afraid of moisture.

Features of the form and installation of ventilation pipes

Ducts can have a round, rectangular or oval cross section. The form is selected based on the specific ventilation system.

Pipes of rectangular cross-section in comparison with round are more convenient in installation and are more compact, but air is worse. They will require more effective forced ventilation.

The designs of the round and oval section can be straight and spiral.

The latter are more durable due to the ribs of rigidity, located along the entire length, but also cost significantly more because of the increased consumption of material during manufacture. Spiral channels are advisable to use on long straight sections of air ducts. Structures with low rigidity in such cases can sag under their own weight.

Pipes of rectangular cross-section are only stitches. When using them, the length of straight sections of the main line should not exceed several meters to avoid sagging and deformation. Rectangular ducts are available as separate sections, connected by welding or flange locks. It is possible to dock with metal rails.

Pipes of rectangular cross-section are only stitches. When using them, the length of straight sections of the main line should not exceed several meters to avoid sagging and deformation. Rectangular ducts are available as separate sections, connected by welding or flange locks. It is possible to dock with metal rails.

For some sections of the ventilation system, corrugated, semi-rigid pipes with a variable shape are required. They are made of aluminum tape, stretched on a steel wire frame with ribs of large cross-section. Such channels can be bent at almost any angle, which is convenient for mounting the swivel sections of the vent line. High flexibility allows the use of semi-rigid structures only in short sections.

Important ! A significant drawback of the aluminum pipe is the increased formation of water condensate on the outer and inner walls as a result of air cooling. The accumulated moisture accelerates corrosion and significantly reduces the life of the aluminum duct compared with plastic.

A cheaper version of the corrugated structure is its plastic counterpart, without a wire frame. The PVC corrugation is lighter and not corroded, but it is fire hazardous, therefore it should not be installed in rooms with high temperatures. Usually, plastic is not as strong as steel, but for complex operating conditions it is possible to use corrugated polyvinylchloride of superheavy type. It has a significant mechanical strength, at least 1100 N by 5 centimeters long.

When a ventilation device is installed within a building, it is common to use manifolds of different shapes and designs to achieve optimum air extraction efficiency.

When installing air ducts in a residential area, you need to take into account a number of important points. The ventilation ducts should have an aesthetic appearance, and ideally and completely hide under the ceiling or wall panels. If you can not hide the channel, you should use a rectangular plastic pipe. It is more compact and fits better in the interior. It is advisable to choose an air duct of the same color as the surrounding wall. In residential areas it is difficult to install a large and noisy fan for forced air injection, but small sizes of private houses allow you to restrict passive ventilation without the use of superchargers.

In addition to the constructions described above, air ducts made of thick-walled cast iron ducts, which are usually used in the sewerage system, can be installed in residential premises. Their main advantage is a price much lower than that of aluminum and plastic counterparts.

In its simplest form, cast-iron ventilation is a tube with a protective cap, protruding from a roof or from a cellar.

This design has many drawbacks - a large mass, the complexity of installation (it can not do without gas welding) and an ugly appearance. Cast iron is prone to severe corrosion, therefore, over time, the channel may become clogged with rust. These days, such highways are almost never used.

You can make an air duct from a plastic canal.

It is also much cheaper than vent pipes, but compared to cast iron it is easier, easier to install and more durable.

Add to bookmarks

Formation of ventilation system in a private house

Excursus in history: the causes of the problem

Owners of old houses, where there was no major repair for a long time, practically do not know the problems with ventilating the living quarters, while the owners of new buildings have this issue particularly acute. The question arises, what is the reason for this trend, because new houses seem to be built in accordance with all existing requirements, but the ventilation system in them is often not ideal. As a rule, in private houses of old construction, where windows have not yet been changed for plastic ones, there are really no ventilation problems. Small the ventilation pipe in the kitchen for the output of carbon dioxide is enough to keep the air in the house always fresh. This is possible thanks to the building materials that were used before, and wooden windows that still allow enough air to flow, ensuring its natural current throughout the room.

The houses of the new construction use modern "non-breathing" materials and plastic windows, which, although they are more durable, but completely block the air current. After a major overhaul of an old building, ventilation problems are not uncommon. Poor ventilation in the house provokes health problems for owners, leads to the accumulation of carbon dioxide. Such phenomena as high humidity in a dwelling, mold on the walls, are the main phenomena that can be observed with poor ventilation. Many experts in the field of construction come to the conclusion that it was the era of plastic windows that gave rise to a lack of fresh air in residential private houses.

Ventilation and exhaust pipe in the house

Most of the ventilation system in modern homes is designed at the construction stage, but if this system was not provided, it is possible to fill this omission. It is quite possible to make a ventilation system with the necessary ventilation outlets in an old building, which will help to avoid the negative consequences of lack of adequate ventilation. In construction, as a rule, three types of air exchange systems are used: natural, supply and extract and supply. Natural ventilation in a conventional house with more or less modern repair is not very effective, since if the rooms have plastic windows, they completely block the natural air circulation. What makes it impossible to use all the known natural ventilation system, which is so common and effective in multi-apartment buildings.

In addition, the natural ventilation system operates at the expense of air temperature differences in the room and on the street, which leads to the fact that such a system completely ceases to function in a private house during the summer period.

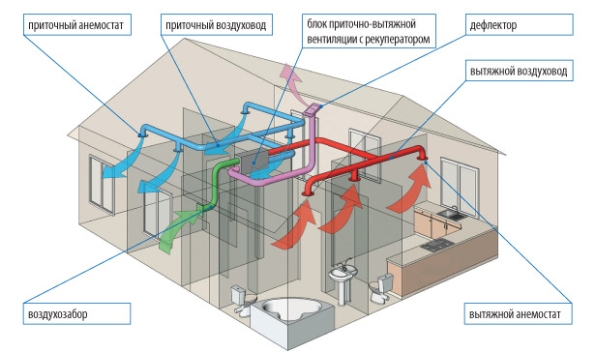

For a private home, a more suitable option is a ventilation system capable of injecting and venting air, so it is better to take into account the supply or supply and exhaust system.

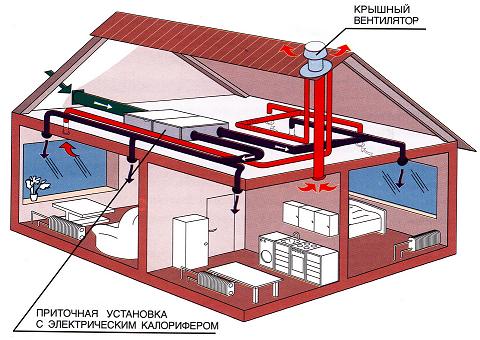

The supply system is ideal for houses whose area does not exceed 300 square meters. m. If the area of the house is much larger, it makes sense to use a supply and exhaust system.

The supply ventilation system in a private house

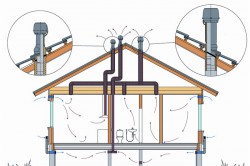

The principle of the supply ventilation system is quite simple. On the roof of a private house, usually above the kitchen, two are installed - this is the basis for future ventilation. One tube serves to inject air into the room, the other - to output. The exhaust pipe, which is intended for putting fresh air into the room from the street, is equipped with a special fan, often with an automatic system of switching on and off and an additional power controller, which allows to regulate the intensity of air intake to the ventilation passages.

Ventilation passages are formed in such a way that fresh air enters the bedrooms and other living quarters, and then, passing through the room, naturally gets carried away into the corridor, the kitchen and the bathroom where the outlets are located. The second exhaust pipe is used just for air extraction and should have a built-in hood, although in some cases you can do without it. So, the second exhaust pipe is connected to the ventilation ducts, which must be laid in the bathroom and the kitchen.

Thus, the injected air will enter the bedrooms and then be pushed into the kitchen and the bathroom, which will prevent the accumulation of moisture in the room and unpleasant smells from the kitchen. This way of organizing ventilation in a private home is extremely effective. It is worthwhile to consider in more detail how to properly install such exhaust systems in a private home, and in addition, what tools and materials will be needed for this.

Home Air Intake System

In the already constructed house it is extremely problematic to arrange ventilation ducts, since in this case it is necessary either to make holes in the wall, which is not always realistic, or to be located indoors, which is not very convenient, since this kind of communication seriously spoil the interior design. If it is a private house, the best option is to place the ventilation ducts in the attic, making holes in the ceiling under the ventilation outlets. To form a ventilation duct for air intake, it is necessary to use special ventilation ducts, which, as a rule, are made of non-flammable plastic and metal-plastic, similar to that of which glass units are made.

There are two types of air channels: round and flat. It is better to take a flat, as it is much easier to mount. The market offers a wide range of nets, valves, connectors and grilles, which will also be useful for the formation of a ventilation system. It is best to make two vent outputs in one room, so ventilation will be much better. The amount of material is taken from the calculation of the area of the room. The air duct is formed exclusively for residential premises, so that air is pushed towards the bathroom and kitchen. The formed airway ducts are attached to the pipe through which air enters the room.

The system of air outlet from the house

The exhaust pipe in the house also plays the role of a chimney. As mentioned earlier, for convenience, it is best to have a hood in the kitchen area. This arrangement is not accidental, since if the duct for the duct can be as long as desired, the air outlet should be as short as possible. This reduces the likelihood of condensation and other related problems. In addition, in any kitchen there is a gas stove, which is a powerful source of children, carbon dioxide emissions and so on. When forming the outgoing channels, it must be remembered that the air that will be discharged through them will in any case be warmer than the surrounding environment, therefore it is necessary to take care of the insulation of these channels in order to prevent the formation of condensation on the walls.

Air ducts are also laid in the attic above the kitchen and bathroom. In the exhaust pipe, it is necessary to arrange a fan, which will discharge air from the room. In addition, it is possible to connect an electric hood to the exhaust pipe, which is located above the gas stove, but in this case it is necessary to connect the electric hood outlet slightly above the exhaust fan's wall by means of a lateral tie and fastening with a flexible duct. In the event that the heating boiler is located in the kitchen, its hood is attached in the same way to the exhaust pipe by means of a tie-in.

Ventilation in a specially equipped boiler room

Often in private houses a small room is allocated for the boiler room. In this room it is rational to make a separate ventilation system to ensure a stable output of the decomposition products during the heating season. To form quality ventilation on the roof above the boiler room, two exhaust pipes are installed. There is no need to do ventilation with a forced-delivery system, since the fan will be superfluous when extracting the decomposition products of the boiler. Firstly, it will be constantly clogged with fire, and secondly, it will only hinder the withdrawal of vapors and gases.

In addition, the gas mixture escaping from the boiler is hot enough, but, as you know, hot air always rises. To ensure that no condensate forms on the pipe that emits hot air, it must be insulated with non-flammable materials. The second exhaust pipe, which can be located on the roof of the boiler room, serves both for withdrawal and for introducing air. In this duct it is advisable to install a fan capable of operating in two directions. In this case, the ventilation system will function as a quality chimney.

Roof and ventilation system

Many people wishing to carry out the ventilation system face some problems related to the correct location of the exhaust pipes on the roof. It must be remembered that, before you begin to chop the roof slate, you need to make a clear plan for the entire house ventilation, based on the layout and the area of the house. It should be noted for yourself, how many inputs should be in the chimneys on the roof. To form the hood on the roof you need a special pipe. The best pipes are suitable for ventilation or, in extreme cases, stainless steel pipes. Before installing a vertical pipe on the roof of the house, it is necessary to make all necessary holes in order to further simplify the process of connecting the ventilation ducts.

All the places of abutment of the exhaust pipe to other surfaces must be sealed, and for this you can use any sealant and even cement mortar. Continue the installation of the ventilation system only after the sealant has solidified and the pipe is completely fixed in one position. The exhaust pipes should stand straight, without heeling, since otherwise the possibility of a large amount of condensate forming when the water vapor settles on the inside of the pipe is high.

A few words "about the main thing" in conclusion

The formation of a ventilation system in a private house is quite a simple task, if you first think over the plan of this structure. It is worth remembering that ventilation will be used in the future for more than one year, so it is worthwhile to make sure that all work is done correctly. In addition, it is worth remembering that low-quality materials that are not suitable for the formation of ventilation ducts, should not be used.

It is highly advisable to use materials that are prone to corrosion, since a large amount of water vapor is extracted through the ventilation system, which will eventually lead to corrosion, especially if a large number of metal elements were used.

Separately, it should be said about fans and air heaters intended for installation in exhaust pipes. These units, as a rule, come with an automatic system of switching on and off, and in addition, with the possibility of switching on by a person. When considering these units in detail, we must admit that in houses with a relatively small area it is better to use those that are turned on by a person, since an excess of incoming air from the street in the winter season will inevitably lead to a loss of heat in the room.

The efficiency of engineering systems is determined by the characteristics of individual elements and compliance with the installation technology. In order for the ventilation pipe in a private house to perform its functions, it is necessary to select and install the air duct correctly. It should take into account the type of ventilation, area of premises and the planned amount of costs.

Private house ventilation system

Principles of choosing a vent pipe

Ducts for ventilation installation must ensure the passage of air flow according to the indices specified in the design documents. In addition, they need to differ:

- tightness;

- resistance to fire;

- minimum dimensions;

- compliance with sanitary and hygienic standards, including the level of noise produced.

Types of ducting and use

Depending on the different characteristics of the pipe, ventilation is classified according to the following characteristics:

- form of section;

- used materials.

The most popular are ducts with a round or square section. Round tubes are easier to manufacture, require less material and have good aerodynamic performance. Air ducts of square and rectangular cross-section are more difficult to manufacture, they weigh more and differ with increased noise level. But they take up less space and easily fit into the room with false ceilings. Usually a rectangular ventilation pipe is used for installation in administrative buildings, apartments of multi-storey houses and country cottages. Round air ducts are more in demand in production rooms, where functionality, rather than aesthetic characteristics, is more important.

Round ducts

As a raw material for the manufacture of ventilation pipes use:

- The zinced steel.It is resistant to corrosion, maintains its characteristics in a temperate climate and can be used in rooms with high humidity.

- Stainless steel.It is used for the manufacture of air ducts, which ensure the transfer of air flows at temperatures up to + 500 ° C. Ventilation pipes made of heat-resistant steel are used in conditions of exposure to aggressive environments - in factories of heavy industry.

Rectangular vent pipes made of stainless steel

In addition, the ducts can differ in their design and rigidity. Depending on the method of production, they can be straight, spiral-wound and spiral-welded, and for stiffness - flexible and rigid.

The most demanded are ventilation tubes of hard type, round or square section. They are used to build systems with high demands on strength and are characterized by ease of operation and installation, but require reliable attachment, since they have a significant weight.

Flexible air ducts

Flexible ducts are a corrugated hose, which is based on steel reinforcement made of wire, and metalized polyester is used to make the walls. They are small in weight, easy to install and maintain. The shortcomings of the corrugated air ducts include low sound insulation and a corrugated surface, which reduces the speed of air flow as it moves. Which pipes for ventilation should be selected, determined, taking into account these characteristics.

For fixing air ducts, when installing a ventilation system in a private house, use a flanged or flanged connection. In the second case, a band of thin sheet steel and metal slats serve as a fixing element. With flange connections, the ducts are fastened together by flanges, and seals are used for sealing.

Features of ventilation installation

The technology of laying ducts is a sequence of certain operations and depends on the type of ventilation system. However, the installation of the engineering network is preceded by it, the selection of pipes and the marking of their location.

Installation of natural ventilation

The system is laid even during the construction of the house or installed in specially designed for this channel. Installation of natural ventilation consists of the following stages:

- fixing the air ducts;

- installation of grilles and deflectors;

- provision of air inflow due to supply valves;

- installation of hoods in the kitchen;

- installation of fans in the bathrooms in the grilles of ventilation ducts working on blowing.

It should be borne in mind that a ventilating circular tube will better provide traction, and a change of air will be more effective.

The scheme of natural ventilation of a private house

If, with natural ventilation in the premises, the air is dry and there is a musty smell, it is necessary to ensure the air supply through an additional valve or a slightly opened window. The reason for high humidity and the appearance of mold is insufficient outflow. Eliminate this defect after the completion of construction is quite difficult, and the easiest way - ventilation forced type.

Installation of forced ventilation

This type is indispensable in a country house with a large number of isolated rooms and rooms with high humidity. Installation of forced ventilation is performed as follows:

- establish a block of supply and exhaust ventilation, placing it on a warmed attic;

- connect air ducts to it;

- mount the air intake on the outer wall so that the distance to the sewer risers and the chimneys is at least 10 m;

- if the air ducts are not installed during the construction of the house, then during the installation of the system they are fixed according to the layout, while the supply ventilation pipe should be closer to the windows or on the opposite side of the door;

- connect the air ducts with the unit by means of corrugated pipes;

- conduct insulation of ventilation pipes;

- install on the ends of the air ducts of the grate, and on the intake - sockets-anemostats.

The scheme of forced ventilation of a private house

The optimal choice of ventilation pipes, compliance with the technology of their installation and regular maintenance of the system will ensure the supply of fresh air to the premises of the private house and will create a comfortable microclimate for its inhabitants.