Fastening the chimney to the wall with your own hands. Chimney from a sandwich pipe to a bath

The nuances of creating a chimney with their own hands

One of the important elements of the heating system is the chimney. Now many owners of a country house dream of an attractive appearance of their home. This directly applies to the chimney. But not only beauty is a fundamental factor in the design of the chimney.

First of all, the chimney must ensure an efficient removal of combustion products and proper air purification.

How to make a good chimney with your own hands?

Scheme of the device of the internal chimney and the external structure.

Basic requirements for the performance of work

It is necessary to do the right choice of one of the furnaces before installing the chimney with your own hands. This is an extremely responsible job. Even the cheapest Swedish oven has a cost of at least 70 thousand rubles. If there is a need to heat multi-storey buildings and fireplaces, then not cheap Russian furnaces should be purchased. Their price is from 100 and more thousand rubles.

To build a functional and qualitative chimney, you need to correctly draw up a plan for the removal of combustion products. When planning, one should take into account the fact that the height and diameter of the chimney depends directly on the furnace, fireplace and boiler.

Mandatory conditions for the design of the chimney:

Installation of the boiler to the chimney.

- A pipe to be laid in a heated room is not necessary to isolate. The device of isolation is necessary for 60 cm before overlapping (it is called "sandwich").

- It is strictly forbidden to apply the gasket through the floors if the pipes are not insulated.

- Channels that pass through unheated attics need to be insulated.

- The chimney must be at least 5 m high.

- When determining the parameters of the height of the pipe, the ventilation ducts of the house, the roof ridge and other elements, one should be guided by the preservation of their geometric proportions.

- Compliance with fire safety rules during installation works. In the presence of a wooden surface, they should be treated with materials that do not allow the combustion process.

When working on the design of a chimney, it is thus necessary to distribute the main characteristics so that the draft of the pipe increases with its height. This is the only way to achieve efficient functioning of the chimney. Otherwise, the system simply "chokes" the smoke, which must properly leave the chimney pipe.

The structure of a typical chimney pipe made of bricks.

Mounting the pipe to the wall with your own hands is done every 2 m with clamps. The same work needs to be done in the corner sections of the pipe. The protruding part of the pipe is attached with separate stretches.

A thermally insulated pipe, called a "sandwich", is most suitable for making a chimney. The fact is that when this structure is functioning, the process of removing combustion products occurs. During this process, no condensation is formed and a large amount of soot is deposited. This type of chimney has a number of advantages, the main of which are its durability and easy maintenance (more precisely, almost its absence).

Chimneys should have the maximum permissible height. The external part of the structures must meet the following building codes:

- in the case where a flat roof is installed, the distance must be at least 50 cm;

- at least 50 cm apart, a pipe should be located in relation to the ridge;

- if the height from the ridge is from 1.5 to 3 m, then the pipe should be set so high that it will not yield to the height of the ridge;

- if the outlet from the chimney exceeds 3 m from the roofing ridge, then it must be straight (in the extreme case not exceed 10 °).

Installation of the structure

To create a chimney with your own hands for stoves, you will need:

Scheme assembly diagram.

- trumpet;

- a set of metalwork tools;

- bulgarian;

- scissors for metal;

- level;

- roulette;

- clamps;

- sealant;

- brackets;

- self-tapping screws;

- galvanized sheet;

- heater.

The two-circuit design by its own hands is installed according to the principle "from the bottom up". That is, first they mount heating objects, and then proceed to install the chimney. The main rule, which should be taken into account in the installation - it is absolutely complete protection of the structure from moisture on the insulation. To provide such protection, you should use a special sealant, which is resistant to an operating temperature of about 1000 º.

It is necessary to join all the working joints with special clamps. The pipes are fixed by the brackets along the entire line of their laying. The slope of the horizontal sections of the entire structure should be less than 1 m. Sites should not come into contact with electrical wiring and gas pipes.

The working channels of the future chimney should be placed by their own hands along the walls or internal partitions of the building. Particular attention should be paid to the fact that the walls were not built of combustible materials. But next to the insulated building chimneys can be placed. Only first it is necessary to fully insulate these structures (in this case pipes).

Care for chimneys is quite simple. This requires only the first and last day of the heating season. It is only necessary to check with your own hands the tightness of joints and seams, as well as the quality of the draft in the chimney. If there is free time, you can also clean the soot from the inside of the chimney.

The outer part of the pipe is usually covered with galvanized iron, as well as decorating with your own hands any colors preferred by property owners.

Assembling and editing the sandwich-pipes themselves with a video lesson

Owners of country houses and villas have to take care of heating the room yourself. Any generator of thermal energy, in addition to an electric boiler, must be equipped with a system for venting the combustion products into the atmosphere. Therefore, when organizing heating, a lot of attention will have to be given to the chimney.

Owners of country houses and villas have to take care of heating the room yourself. Any generator of thermal energy, in addition to an electric boiler, must be equipped with a system for venting the combustion products into the atmosphere. Therefore, when organizing heating, a lot of attention will have to be given to the chimney.

Today, the most popular is the practical, functional and aesthetic chimney in the form of a sandwich tube. Its installation by oneself is a fairly simple and completely safe undertaking. Only in advance it is necessary to take care of the purchase of high-quality materials, and see the video instruction on installation of the sandwich-chimney.

Features of the design of sandwich tubes

Chimneys in the form of sandwich pipes are manufactured using a new technology. Layer construction assembled from various materials. and resembles an ordinary sandwich. Its base is two different in diameter pipes, which are embedded in each other. Between them is placed a heat-insulating gasket made of basalt fiber or mineral wool. Such materials are resistant to high temperatures and are not susceptible to active chemicals. They perfectly hold heat and extinguish sound waves.

Unite double-circuit pipes can be in several ways: flanged, bayonet or "cold bridge". Chimneys can have a different diameter and thickness of the thermal insulation layer. The type of construction depends on the temperature conditions of the environment, where it will be operated and from its designation.

Sandwich-tubes have not only a straight form. Because the the chimney must pass through floors and roofing. and on its way can meet various elements of the building, the design contains the sectional fragments and additional elements for their connection.

The complete set with a sandwich-tube includes:

- tee;

- weather vane - protects the structure from wind and prevents back draft;

- the knee with an angle of 45 and 90 degrees;

- cone for free flow around;

- audit to check the condition of the chimney;

- protective fungus.

If the heating furnace operates on gas. then the weathercock and fungus are not used.

Advantages and disadvantages of chimneys made of sandwich tube

The positive aspects of the design include:

In addition to all of the above, sandwich tubes have an attractive appearance. which will persist for many years.

To drawbacks of the design can be attributed only its rather high cost and not very simple installation. But all other advantages of such disadvantages of sandwich pipes pay off.

Materials for making sandwich tubes

Virtually all the sandwich-chimneys offered in construction stores look the same. But since their manufacturing is a profitable business. in the market there is a low-quality production. Therefore, when acquiring a structure, it is necessary to pay attention to the quality of the steel, especially the one used to make the inner tube.

Quality products must have technical documentation. in which must necessarily be prescribed used for its manufacture of steel.

Check stainless steel for quality you can use the national way with a magnet. If it slips over its surface and does not rest on it, then the material contains alloying additives. Stainless steel, on the surface of which the magnet is fixed, it is not worth buying.

Installation of sandwich pipes by own hands

Installation the chimney must pass by all the rules. only then its operation will be durable and safe.

Basic rules for installing sandwich tubes

To heating was effective. most of the chimney must be inside the room. This will reduce the temperature difference.

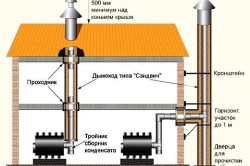

Assembly and installation of a chimney from a sandwich tube inside the house

Install the design with their own hands is fairly straightforward. The main thing is to connect each section consistently and correctly.

Installation chimney from a sandwich-pipe with my own hands is finished. Now you can begin to disguise the remaining unsightly form of the system. For example, plaster and paint over the ceiling.

How to install a sandwich tube outside the house?

The assembly and chimney installation through the wall with their own hands is made in the event that, due to the structural features of the roof, it is impossible to make holes in it. In addition, such an installation will save the interior space of the room.

During installation and during operation of the sandwich-pipe it is forbidden:

- mount the chimney to units operating on coal;

- install a galvanized structure in rooms with a high level of humidity;

- use as a fuel items with paint and lacquer and construction waste;

- place chimney sections near flammable materials;

- use a design for drying shoes, clothes and various household items.

Correctly mount chimney from a sandwich-pipe quite easily with your own hands. You may need only additional tools, if necessary, make technical holes, and a ladder or a cock for work on the roof. To speed up the installation process at different levels, you can find an assistant.

Sandwich-pipes as the most acceptable version of the chimney

The most common option for installing a chimney for fireplaces and heating ovens is a stainless sandwich tube, which is characterized by high performance, as well as ease of installation and safe use.

What is a sandwich tube?

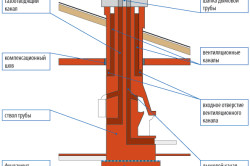

Sandwich Pipe Assembly

The most common variant of stainless steel pipes is a sandwich construction. This option is an improved type of traditional sheet metal pipes. The name of the product was obtained thanks to a three-layer construction:

- the inner tube is made of stainless steel, as a rule, AISI 316 brand, thickness up to 0.7 mm, is used for it;

- layer of thermal insulation - basalt wool, thickness up to 30 mm and density up to 125 kg / m3;

- outer layer - stainless steel, up to 0,4 mm thick, most often use AISI 304, which is characterized by high resistance to acidic environment.

The purpose of the inner tube in carrying out fumes and gases, which is why it is made of heat-resistant steel, provides tightness and integrity under the influence of high temperature, can withstand heating up to 900 ° C.

The inner layer provides heat insulation, thanks to which the chimney practically does not form a condensate due to the difference in temperature inside the pipe and outside. The emergence of condensate and served as an impetus for the development of sandwich technology, because previously it was necessary to insulate the chimneys, mounted from thin-walled pipes.

Composite elements of pipe sandwich

Chimney

The outer layer is necessary to ensure the protection of the entire structure from the effects of various weather factors, therefore it is made of heavy-duty stainless steel with a high resistance to aggressive media.

- installation of such a design for the chimney ensures the absence of condensation;

- less soot accumulation, which means simplicity of operation;

- beautiful, aesthetic appearance of the chimney;

- fire safety;

- ease of installation, with their own hands, without the involvement of specialists;

- long service life.

Elements of a sandwich-pipe

The chimney unit is a simple, but multi-element process, especially when it comes to connecting a fireplace or a stove with a rear or side nozzle. Only the assembly of fireplaces with an upper chimney connection will have a simpler design.

Elements of a chimney sandwich:

Elements of a chimney sandwich

The start-sandwich is necessary for joining a single-walled pipe with a heat-insulated one. The fireplace, stove or other heating system is connected to the main chimney by a single-walled or corrugated pipe with a slide gate valve.

Further, depending on the location of the fireplace in the room and the intended location of the chimney, various elements can be used: the knee, the bracket, the adapters, the horizontal pipes, the vertical ones. All elements are joined together by clamps.

Crimping clamp is a metal ring that is tightened at the junction, it is wide enough and ensures reliable fixation of the elements, preventing depressurization during operation.

Adjustable wall bracket for fixing the chimney pipe

In order for the sandwich pipe for the flue to fit against the wall and be fixed, use a bracket. Thus, fixation is carried out, at the same time it must be remembered that the bracket should not be installed at the junction of the two pipes, it is best to mount it in the middle. The bracket with one side is fixed to the wall, and the other with the clamp to the pipe.

If the height of the chimney is more than two floors, it is advisable to install a discharge station. It is a square of stainless steel with pipe elements on both sides, installed after the overlap. It is important to remember that passing a pipe through a wall or an overlap should not coincide with the place of docking.

Before the passage through the roof, it is necessary to install a rosette, on top of it a conical croat, then a octopus or apron, and on it a vertical pipe, preferably one meter in height. The final element is the head, it is also called the cone, fungus. If the roof is made using combustible materials, it is necessary to additionally install a spark arrestor on the pipe, it will prevent undesirable ignition.

Mounting the sandwich-chimney with your own hands

Variants of the location of sandwich chimneys

Despite the large number of elements, it is quite easy to assemble a sandwich with a chimney without the involvement of specialists. Before starting work, it is necessary to measure, determine the location of future joints, turns, which will affect the number of additional elements.

The next stage is the preparation of technological holes in the wall, ceilings, roof, in the course of placing the chimney. When passing through the wall, it is necessary to take into account that in the horizontal position it is not recommended to lay a chimney with a length of more than one meter. And if such a necessity has arisen, then it is necessary to place the pipe at an angle, the optimum will be 45 °. When passing through the wall, the chimney should not be located near unprotected structures, the minimum distance is 380 mm, otherwise the pipe must be further insulated.

To install the chimney with your own hands went easily and in the future there were no deformations, you should start mounting below the fireplace or another heating device. Do not conduct a chimney near a variety of utilities (electrical wiring, gas pipeline).

There are two types of installation of stainless steel sandwich pipes:

Chimney assembly by smoke and condensate

If you assemble the design with your own hands it is supposed "by smoke", then this will ensure unhindered weathering of gases and prevention of their infiltration into the room. To perform such an assembly, every subsequent structural element must be worn on the previous ones.

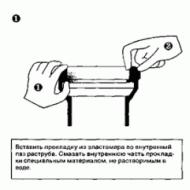

In order to collect the chimney from the sandwich-pipes "by condensate" by their own hands, each next element should be inserted into the pipe of the previous one. This option will prevent the penetration of moisture into the heater, and protect the pipe from corrosion, but if the joints are loose - the smoke can penetrate into the room.

Experts advise necessarily all horizontal parts of the chimney to do "by smoke," and vertical, which pass through unheated rooms on the roof to collect "on the condensate."

By self-assembly of a chimney from a sandwich tube, one can use one of the external output options

Installation of sandwich pipe

The first option is less preferred, especially for solid fuel-fired heaters, since a large amount of smoke will form and the thrust in the horizontal position will be minimal.

Video: Installation of chimneys through the finished roof

Installing and securing the chimney

No heating device can operate without a good gas exhaust system. Often when building a holiday home, they forget to include a chimney in the project. In this case, it is necessary to lay it directly through the wall. Many decide to make a chimney with their own hands.  This problem is solved in several ways. Starting from the classic standard brick masonry and building in the main frame of the house, and including complex constructions of steel pipes or other modern materials. All options differ in complexity, materials, labor and time costs, efficiency and heat capacity, the ability to increase the efficiency of the heating system.

This problem is solved in several ways. Starting from the classic standard brick masonry and building in the main frame of the house, and including complex constructions of steel pipes or other modern materials. All options differ in complexity, materials, labor and time costs, efficiency and heat capacity, the ability to increase the efficiency of the heating system.

The most suitable option is the construction of steel pipes - a chimney-sandwich. Self-assembly, as a rule, does not cause difficulties, if you understand the structure of the chimney-sandwich.

The main advantages of chimneys sandwiches

- Metal pipes are a long-established and widespread element of the chimneys. This is due to a number of reasons.

- Pipes have round section, on which gas exchange between the furnace and the environment is easier. This is important for the organization of flow of air flows inside the chimney.

- Only pipes allow to arrange smooth and flat surface, on which the combustion products do not settle, and even if they settle down, it occurs evenly, and is easily eliminated by cleaning.

- Installation of a chimney with your own hands is many times simpler than comparable chimneys made of bricks.

The gases passing through the smoke channels are saturated chemically aggressive impurities, therefore cause corrosion of the metal, which occurs against the background of temperature fluctuations, changes in humidity and other conditions. In this case, the service life of the chimney is reduced by a factor of ten, so more resistant substances, for example stainless steels, are added to the pipe material. Besides corrosive phenomena. there are still some other complications.

- High conductivity of metal in a short time reduces the temperature of the gases passing through the pipes, as a result, it turns out that the chimney-sandwich, from the place where the bracket is fixed, cools down, most of the heat is stored inside the room.

- As a consequence, a significant contrast of temperatures at different ends of the pipe provokes simultaneous linear expansion of the bodies under the influence of the combustion energy of the fuel, condensate forms on the surfaces.

- The outer wall of the pipe is heated to a temperature dangerous for environmental objects, so an additional heat-insulating layer is required that does not let out excess heat.

To solve these problems it was possible to the creators of chimney-sandwiches.

The device of a chimney of a sandwich

Thanks to the English, who like to call everything that consists of two layers and fillings, a sandwich, the chimney has acquired such a name. The sandwich consists of two pipes different diameters (inner and outer metal contours). Inside between them have a powerful insulating material, which is customarily made from basalt rocks.

The chimney consists of many details. Firstly, naturally pipes. Secondly, bracket. thirdly, other details: clamps, adapters, tees, pipes with revision, ensuring the correct operation of the structure and the effective use of structural materials. The bracket allows you to comfortably attach the chimney to the wall with your own hands.

The meaning of such a device in effective work, in particular, the removal of products from the furnace. External circuit is reliably protected from overheating, and internal - from contrast of temperatures. The interlayer between them reliably protects against the appearance of moisture, condensation and efflorescence on the surface of the pipes; The thrust, which should appear in the air streams, works correctly.

The meaning of such a device in effective work, in particular, the removal of products from the furnace. External circuit is reliably protected from overheating, and internal - from contrast of temperatures. The interlayer between them reliably protects against the appearance of moisture, condensation and efflorescence on the surface of the pipes; The thrust, which should appear in the air streams, works correctly.

Internal tube always thicker and covered with a thick layer of stainless steel, which has enhanced properties against corrosion and burn-out. Outer circuit. as a rule, make it more economical, with less cost, from conventional galvanized iron. The installer must choose between price and quality, since the difference between stainless steel and galvanized iron is very high. Internal loop material should be chosen, guided by knowledge of its resistance to thermal contrast and high humidity, corrosion properties. The outer pipes must be rigid, because they are the skeleton of the structure.

Preparing for installation

When installing smoke ducts from sandwich pipes, you do not need to build an additional cement foundation yourself, as required by a chimney made of bricks or ceramic masonry, because small weight the design acquires the next advantage of the metal installation in front of the ceramics and bricks. But do not underestimate the task facing you, because you do not just need to fix the bracket, although it's really easy to make by yourself.

Do not forget about the existence of a number of rules and recommendations that need to be understood and thought through at the stage of choosing tools and materials. Note that it will play into the hands of the ability to draw a diagram of the projected installation, determining on it all the dimensions. Experts with experience, who probably know how to install a sandwich chimney, are often advised to pay attention to such moments as the intersection of the chimney and the roof surface. overlapping, etc.

Sometimes a boiler or furnace furnace is mounted on a rough floor. With such calculations, it is necessary to calculate thickness of all layers of the floor. not forgetting the installation of the floor surfaces, and install the heating devices on the stands so that the unit fits perfectly to the outlet for the combustion products.

Sometimes a boiler or furnace furnace is mounted on a rough floor. With such calculations, it is necessary to calculate thickness of all layers of the floor. not forgetting the installation of the floor surfaces, and install the heating devices on the stands so that the unit fits perfectly to the outlet for the combustion products.

Chimney installation

Installation of a sandwich-chimney start from the outgoing end of the heating equipment pipe. The first part of the chimney looks like a piece of pipe that is not covered with warming layers. First fix the bracket, and already on it a branch pipe. If you start mounting the structure from a single sandwich tube, the warming material will melt, a stone formation is formed that will destroy the chimney. For this the bracket must be installed at a height, protecting from overheating. The result of improper installation is most often the defect of heat generating equipment, and even the ignition of fire-hazardous materials.

The detail is pounded into the socket, fixed, installing the bracket, and closed with a plug. Then the details of the smoke outlet structure are connected in order, by fastening the joints of the pipes with the clamping clamps.

If there is a possibility of a significant increase in pressure in the channel, the junction points, just in case, special couplings. Often when installing steel pipes, heat-resistant sealants are used, which cover the joints. The more insulated the chimney, the more accurate the pull.

Despite the excellent insulating properties of "sandwiches," in the pipes when overlapping occurs some probability of overheating and ignition adjacent to the pipe materials. To guarantee a certain level of fire safety, it is advised to increase the thickness of the thermal insulation layer at the joints.

Despite the excellent insulating properties of "sandwiches," in the pipes when overlapping occurs some probability of overheating and ignition adjacent to the pipe materials. To guarantee a certain level of fire safety, it is advised to increase the thickness of the thermal insulation layer at the joints.

To fix the chimney with your own hands is quite easy, for this it is enough to understand the device and know the basic safety regulations. After installation, it is necessary to properly maintain the chimney and clean it to reduce the risk of accidents in the operation of the stoves.

There are effective folk remedies for chimney cleaning. So, recently it is often advised to occasionally heat the stove with aspen wood: as a result, a powerful flame is produced, which burns down the sediments on the surface of the pipe walls. Do not do this often, you should be careful, because it often provokes fires.

About, how to properly install a chimney from a sandwich tube, as well as how to properly install a sandwich pipe in the bath will be described in this article. And the attached video explains in detail how to install a sandwich tube.

Installation of a sandwich pipe for a chimney

One of the points on which preference is given to chimneys made from sandwich pipes is the ease of their installation. Given that the installation of a sandwich pipe for the chimney is easy to do on their own, the price of work is zero. First you need to decide which type of chimney to be mounted. There are two main options:

- . the inset chimney - the pipe outlet is vertically upward from the ceiling and roof. Through a single-loop adapter from the furnace, pipe modules are mounted, and further, through the tunnel, the pipe is taken out to the attic. Then, through the master flash, the pipe is removed to the roof and is crowned with a metal cap, designed to protect the pipe from getting rainwater in it - the head;

- . drawn through the wall - the meaning is the same, only here the pipe will go to the outer wall of the building.

It is necessary to first make a square hole in the wall under the tunnel. After inserting the tunnel, for fire safety, asbestos and galvanized iron are laid around the hole. Through the tunnel the pipe is led out.

How to assemble a chimney from a sandwich tube

As you know, it is quite easy to assemble a chimney from sandwich pipes. The choice of the method of installation depends on various factors, both practical and aesthetic. In practice, the chimney drawn through the wall is less flammable and more convenient. At the same time, the exhauster is more durable and less susceptible to external factors, such as, for example, rainwater or dew. The external chimney, in turn, can become a pleasant "highlight" of the building - the brilliant pipe will perfectly match with the decorative stone or similar to it wall panels.

Installation includes the following:

- . joining pipes;

- . Sealing of joints;

- . holding pipes through the ceiling, roof or wall;

- . pipe fastening.

At first we attach to or the most common iron pipe of a suitable diameter, because The sandwich tube is not designed to fully adhere to the heating element, due to its high temperature. After that, you can begin to install the two-circuit modules on the initial single-circuit pipe. It is necessary to use a heat-resistant sealant when sandwich pipes are joined - this will minimize the risk of depressurization and its negative consequences.

Do not confuse heat-resistant (black) sealant with automobile (red) - the first withstands much higher temperatures. The composition is applied to the narrow end of the tube, then worn wide. Some masters recommend using a sealant to coat the seam and the outside, others - strongly against this approach. The difference is that if the seam is not sealed from the outside, then the design is more repairable. In order to install a chimney from the sandwich pipes through the wall, you must first prepare a seat for the passage in the wall.

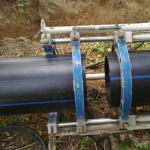

To do this, we make a square hole of the right size, along the edges of which we sew an asbestos sheet, which, in turn, is covered with galvanized iron. We insert the tunnel and, through it, we deduce the first module on the outer wall of the building. On this very module it is strongly recommended to install a special tee to collect the condensed moisture and then drain it. On the tee, the remaining two-circuit pipes are mounted until the required height of the structure is reached.

The assembled pipe is fixed to the wall using brackets - clamps of the required diameter with fasteners. Finish the pipe with a metal cap, protecting the pipe from falling into it of atmospheric precipitation. The procedure for removing the pipe upward through the ceiling is the same as above, only the tunnel will be inserted into the ceiling. To conduct the pipe through the roof, it is convenient to use a flash master - rubber or silicone sealant, which securely secures the module and seals the joints.

Despite the fact that the silicone "master" is much more heat-resistant, a similar product made of rubber will last much longer. The height of the pipe above the roof level is determined as follows:

- . the pipe must be higher than any extensions adjacent to the building or superstructures above it;

- . if the pipe is located less than 1.5 meters from the ridge, then it should be made above it by 5 centimeters, from 1.5 meters to 3 - on one level with the ridge, more than three meters - a little lower;

- . For a flat roof, a length of about one meter is recommended.

Be sure to remember that:

- . The chimney is collected from the stove, i.e. down up;

- . the length of the entire structure should not be less than five meters.

Detailed installation of the sandwich tube for the chimney is shown in the following photos and videos.

Mounting a sandwich pipe to the wall

Mounting of the sandwich tube to the wall is carried out using special brackets, which are a clamp for the diameter of the pipe, attached to the desired surface. Usually, first the bracket is attached, and then a pipe is inserted into it, but you can also do the installation in the reverse order. Fasteners must be installed at least every two meters of the pipe.

Brackets can be made on their own, but it's better to buy ready ones. this installation is more convenient and correct from a technical point of view. Buy fasteners for chimneys from sandwich pipes better directly from the manufacturer. In Moscow and throughout Russia, this can be done in, engaged in the production of everything necessary for assembly, assembly, installation and fastening of sandwich pipes.

A chimney is one of the main elements of heating a country house. Depending on the location, the internal and external chimneys are distinguished. Installation of the chimney can be done by yourself. To carry out this work, no special knowledge is required. Our article will tell you how it is performed.

General rules for installing a chimney

Installation of the chimney with its own forces, although quite simple, but with its implementation you need to know certain rules. Consider these:

- The length of the chimney from the place of its connection with the heating equipment to the final element should be more than 5 meters. Otherwise, the pipe will not generate the thrust necessary to remove smoke and other elements that are harmful to humans, burning elements.

- Transitions of pipes through walls and other ceilings, as well as the flue pipe, located in the attic of the building, must be reliably protected from overheating, which can provoke a fire. For special materials, resistant to high temperatures, for example, basalt mats are used.

Insulator for chimney - mat from basalt

- The design of the chimney must be clearly designed and designed. The main indicators are: the cross-section of the pipe and the height of the chimney.

- For reliability, the chimney is fixed to the wall with clamps, the distance between which depends on the material used. Chimneys of their stainless steel or sandwich-pipes should be fastened every 1.5 m, and a cast-iron smoke channel is attached 0.8-1 m.

- All connections of chimneys in a single system must be located in the human visibility zone. This is required to check the tightness.

All construction work on the arrangement of chimneys should be made, relying on fire safety standards.

Self-assembly of the chimney

Installation of the chimney depends on the material from which it is made. Currently, there are:

- brick chimneys. To install the structure you need a reliable foundation of the chimney. It is not recommended to build a brick chimney on its own;

- metal chimneys;

- smoke extraction channels assembled from sandwich pipes;

- ceramic chimneys - are mounted, relying on the scheme of a chimney, assembled from sandwich pipes;

- polymer chimneys, are mounted in the same way as smoke channels made of sandwich pipes.

Tools required to install a chimney

The chimney device assumes grooves for connecting all the elements in a single system. However, the chimney assembly will require:

- for smooth pipe cutting, a Bulgarian is used;

- drill holes in the joints of pipes more convenient drill;

- screwdriver or a set of screwdrivers;

- for cutting holes in the passage of pipes through the floors, a jig saw is used;

- for subsequent sealing of holes, a trowel and spatula are used;

- for personal protection of the person collecting the chimney, glasses and gloves are used.

A set of necessary construction tools: 1- Bulgarian; 2- the drill; 3- screwdriver; 4 jigsaw; 5- trowel; 6-spatula; 7- construction glasses; 8- construction gloves

Doing any work without personal protection is not recommended.

Installation of metal chimneys

To mount a metal chimney, it is necessary:

- to fit all the constituent elements to the required dimensions;

- in the right places (walls, roof and so on) to make holes. If the chimney is made of stainless steel, the diameter of the holes should be 1.5 times the diameter of the pipe used. For cast-iron chimneys it is recommended to make holes 2 times the diameter of the pipe;

- a chimney is installed;

- in the necessary places the chimney is fixed to a wall or other hard surface;

- the installed chimney is connected to the heating device;

- all necessary sections of the chimney;

- in the upper part of the chimney, a head is installed, which protects the whole chimney from getting rain and foreign objects.

The chimney head protects the pipe from precipitation

Metal chimney, installed in compliance with all rules and regulations will serve for a long time.

In order to improve the aesthetic appearance of the chimney can be decorated with non-combustible materials, for example, ceramic tiles or decorative stones.

Installation of a chimney of sandwich pipes

When building a chimney from a sandwich pipe, all the steps described above must be done. The nuances of assembling this kind of chimney canal are:

- no need to make large diameter holes in the slabs. Sandwich pipes are made in such a way that the necessary insulation is already provided for by the design and it remains only to protect the surface of the overlappings from the effects of high temperatures;

- when sandwich pipes are joined together, the construction adhesive is additionally applied, giving the joint additional strength and tightness.

Sandwich pipes are the most modern building material. By their qualities chimneys collected from sandwich pipes are not inferior to metal ones.

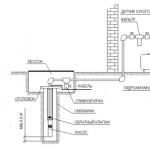

Installation of an external chimney

The installation scheme for the external chimney is somewhat different from the chimney construction scheme located inside the house. To build an external chimney, you will need:

- a hole is made in the wall at a distance of at least 50 cm from the heater outlet;

- fixing elements are installed along the entire length of the chimney along the outer wall, the distance between which must not be less than 1 m;

- according to fire safety rules, a knee is installed between the inner and outer part of the wall. Adherence to walls is reliably isolated from overheating. The lower part of the chimney rests on the installed bracket;

- inside the house, the chimney is connected to the heating equipment;

- the outer part of the chimney is assembled, and is attached to the wall and to the transitional knee;

- the upper part of the chimney is protected by the head.

For an external chimney it is more appropriate to use metal pipes.

Before proceeding with the installation of the chimney, it is necessary to prepare all the necessary components of the system and tools. Installation of the chimney runs according to the above schemes. The main thing - compliance with fire safety standards.

At present, a chimney from a sandwich pipe is considered one of the most popular and practical. Its functionality allows you to apply it in a variety of conditions.

In principle, if you could get high-quality materials from reliable suppliers, then it is very easy to build such a chimney, and absolutely safe. This design has many advantages:

- there is no condensation;

- minimum soot;

- fire safety;

- low weight;

- beautiful appearance;

- easy maintenance.

One of the most important advantages can be called the possibility of laying such a chimney in wooden buildings, especially in the home bath.

Before we tell you how to make a pipe in a bath, it should be noted that when building a chimney in a bath it is necessary to take into account certain requirements that are imposed on the dimensions of the structure and its construction:

How to choose a pipe

Before selecting a sandwich tube, it is necessary to know several characteristic parameters that depend on the heating system used.

One of the main design parameters is the diameter of the pipe. It is designated by two digits - 120/180, where the numerator is the internal diameter, and the denominator is the outer size of the pipe.

The internal diameter is selected in accordance with the working diameter of the branch pipe, the exhaust smoke installed on the heat unit. According to the internal dimension, the opening for the pipe is determined, which will pass through the roof.

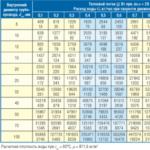

The thickness of the thermal insulation regulates the selection of pipe diameters. And their sizes are selected on the basis of the aggregate of the thermal system:

- woodburning stoves or gas-turbine systems - 50-600 mm;

- solid fuel boilers -50-700 mm;

- diesel generators or gas piston aggregates - 50-500 mm;

- microturbine devices - 50-300 mm;

- gas boilers - 200 mm;

- diesel systems - 200 mm.

It is very important to choose the correct length of the chimney. It should have a vertical part longer than 5 m. Its horizontal component is much smaller: only one meter.

It is very important to choose the correct length of the chimney. It should have a vertical part longer than 5 m. Its horizontal component is much smaller: only one meter.

The chimney should be above the roof ridge by 500 mm, when the distance to it is 1.5 meters. With a length of 3 meters, a sandwich tube can be made at the level of the top point.

If the roof is flat, then the minimum distance between the roof heights and the chimney is taken, is maintained 0.5 meters.

Additional characteristics when selecting a sandwich-chimney are:

- cost of the product. Of course, much depends on the solvency of the buyer, but still you should not buy the cheapest products;

- material of sandwich-tubes;

- thickness of metal.

Nuances that require special attention

Of course, the manufacturer of the product is of great importance. Unfortunately, a lot of fakes have appeared on the market. An ordinary person is difficult to catch all the subtleties, so to avoid making mistakes, it is worth listening to the advice of professionals:

Installation of a chimney for a sauna oven

If the chimney is laid through a heat unit, it can be connected directly to the system or a heat exchanger. The chimney can be laid through the wall, you can mount the outlet through the ceiling. In the figures below you can get acquainted with the layout of the chimneys.

To get the maximum effect from the combustion of fuel, an ordinary metal pipe is diverted from the furnace. From above it is mounted the sandwich-tube itself.

As a result, the maximum temperature is maintained due to the powerful thermal radiation emanating from the pipe. The heating temperature is almost the same as in the furnace. To soften radiation without losing heat on the chimney, a mesh filled with stones is put on. Heated stones will dry the steam room after the furnace has completely decayed.

In some cases, the chimney can be used as a water heater. For this, a heat exchanger is installed in place of the metal pipe leaving the furnace.

Mounting technology

Install a sandwich tube is not very difficult. This design has the maximum fire safety, therefore its connection and fastening can make the person who never was engaged in building.

Installation must start from the bottom, gradually reaching the top. It all starts with a stove.

Step one

When mounting a sandwich chimney, always remember that one end of the pipe is made with a narrowed radius. It is inserted into the next section of the pipe. Due to this connection, soot accumulation does not take place, condensate is easily removed from the chimney pipe. To facilitate this work, you can install special tees.

Step Two

To pass the chimney through the wall, it is dismantled and reinforced, where the pipe bracket will be inserted. Then the outer bracket with two corners is assembled. They play the role of runners for the movement of the tee when mounting the sandwich tube.

To close the wall thick thick 1 cm plywood. It is covered from above with an asbestos sheet and fixed with usual screws.

Then the entire structure is closed with a galvanized sheet, with dimensions of 2x1.20 cm. To free the road, a square hole is made in the sheet.

The bracket is covered with a metal varnish to create a surface protected from corrosion. Especially for the chimney in the adapter, a hole is drilled.

When building a chimney, it is necessary to make a concession, which is a gap between the wall and the channel, which removes flammable gases.

Installation of a chimney passing through the roof

How to properly install the pipe through the roof of the roof? Before installing such a chimney, a galvanized metal sheet is taken. It is applied from the inside to the hole, after which a pipe is removed. Then the sheet is fixed on the roof. If necessary, its edges can be fixed under the edge of the roof.

With a flat roof, a sandwich-pipe for a bath should rise above it to a height of more than one meter. When the height of the deflector exceeds 1.2 meters to the roof, additional extensions are installed, fastened by crimping clamps.

The roof made of fire-hazardous materials must be protected from fire. The chimney is equipped with a deflector having a mesh spark arrestor. The size of the cell is taken as low as possible.

Fixing a sandwich-chimney

Fixing of all parts of the chimney is carried out by clamps. The mounting of the tee is made by a support bracket. The remaining loose flue top requires the creation of a safety net. For example, stretch marks with an angle equal to 120 degrees.

Fixing of all parts of the chimney is carried out by clamps. The mounting of the tee is made by a support bracket. The remaining loose flue top requires the creation of a safety net. For example, stretch marks with an angle equal to 120 degrees.

Docking of sandwich pipes is done with the help of crimp clamps. Docking with additional elements, adapters or tees is carried out by the same clamps, however, the fastening is carried out on each side.

Note that the support bracket does not have to be bought in the store. You can make it yourself. Take two metal corners, with a side of 30 and 50 mm. The desired length is cut and appropriate bolt holes are made.

Final installation

When the assembly is finished, you need to remove the protective film. The overall dimensions of the chimney sandwich must be approximately 5-6 meters from the head to the grate. Seams and available gaps are closed with a sealant.

When the assembly is finished, you need to remove the protective film. The overall dimensions of the chimney sandwich must be approximately 5-6 meters from the head to the grate. Seams and available gaps are closed with a sealant.

It is best to use a heat-resistant sealant. It is specially designed for chimneys, withstand temperatures of 1000 C. It is applied using the following technology:

- Internal pipes - the outer part is covered;

- External pipes - the whole outer surface is sealed;

- When there is a transition from single-walled pipe to double-walled, the whole outer surface is sealed;

- Single-walled pipe and the corresponding module are connected in the same way as the last version.

After carrying out the sealing, it is necessary to carefully check the most fire-hazardous areas, where the heating will have the maximum temperature.

To subsequently make it easier to clean the chimney, an audit is established. It can be removable or have an opening door.

Compliance with fire safety

Even with good thermal insulation, the outer surface of the chimney can be heated strongly. The heating temperature sometimes exceeds 300 degrees. This temperature can easily ignite a dry tree.

Therefore, the construction and installation of chimneys from sandwich pipes requires strict adherence to fire safety techniques:

Therefore, the construction and installation of chimneys from sandwich pipes requires strict adherence to fire safety techniques:

- Do not install a sandwich near combustible materials.

- Sandwich should be at a distance of 25 cm from any combustible surface. If the heating temperature is lower, this distance can be reduced, but remain within 10 cm.

- The best insulation is air. It is not required to fill the box through which the chimney passes, additional claydite or plug it with mineral wool.

- When installing a chimney on the roof, in addition to heating the pipe, it is necessary to take into account the direction of the flow of hot air and flying sparks.

- The elevation of the pipe above the ridge, if the roof is made of fire-hazardous material, should be more than one meter. Pay attention, above the ridge, but not above the roof itself.

Positive and negative qualities of chimneys

About the flaws of the chimney to talk a lot will not have to. Since there are very few of them:

- stainless steel parts are always very expensive;

- the service life does not exceed 15 years. The brick chimney can work much longer;

- due to a temperature jump, a change in the cross section of the pipe is possible. This can cause the entire structure to be depressurized.

The positive qualities of such chimneys are much greater:

Summing up

In principle, the installation of the chimney can be called a simple job. For an experienced person such work will not be very difficult. But if there is even the slightest doubt about the success of the whole event, it is better to turn to professionals and you will have a quality-assembled element. After all, a mistake can be very expensive, the house can just burn.