Specific losses of duct pressure. Calculation of airway pressure

When the duct parameters (their length, cross-section, friction coefficient of air against the surface) are known, it is possible to calculate pressure losses in the system at the designed air flow.

The total pressure loss (in kg / m 2) is calculated by the formula:

where R is the frictional pressure loss per 1 running meter of duct, l is the length of the duct in meters, and z is the loss of pressure on the local resistance (with variable cross-section).

1. Loss of friction:

In a circular duct, the frictional pressure loss P p is assumed to be:

Ptr = (x * l / d) * (v * v * y) / 2g,

where x is the coefficient of friction resistance, l is the length of the duct in meters, d is the diameter of the duct in meters, v is the air speed in m / s, y is the air density in kg / m 3, g is the gravity acceleration (9 , 8 m / s2).

Note: If the duct has not a round but a rectangular cross-section, the equivalent diameter must be substituted in the formula, which for the duct with sides A and B is equal to: dequ = 2AB / (A + B)

2. Losses on local resistance:

Loss of pressure on local resistance is calculated by the formula:

z = Q * (v * v * y) / 2g,

where Q is the sum of the coefficients of local resistance in the airway section for which the calculation is made, v is the air flow velocity in m / s, y is the air density in kg / m3. g is the gravity acceleration (9.8 m / s2 ). The values of Q are presented in tabular form.

Method of permissible speeds

When calculating the network of air ducts, the optimal air speed is taken as the initial data by the permissible speed method (see table). Then, the desired section of the duct and the pressure loss in it are considered.

Procedure for aerodynamic calculation of air ducts by the method of permissible speeds:

Draw a diagram of the air distribution system. For each section of the duct specify the length and amount of air passing in 1 hour.

Calculation begins with the farthest from the fan and the most loaded areas.

Knowing the optimal air speed for a given room and the volume of air passing through the air duct in 1 hour, determine the appropriate diameter (or cross-section) of the duct.

Calculate the pressure loss for friction P tr.

According to tabular data, we determine the sum of the local resistances Q and calculate the pressure loss for local resistances z.

The available pressure for the following branches of the air distribution network is defined as the sum of the pressure losses in the sections located before this branch.

In the process of calculation, it is necessary to consistently link all the branches of the network, equating the resistance of each branch to the resistance of the most loaded branch. This is done with the help of diaphragms. They are installed on lightly loaded sections of ducts, increasing resistance.

Table of the maximum air speed depending on the duct requirements

Method of constant head loss

This method assumes a constant loss of pressure on 1 running meter of the duct. Based on this, the dimensions of the duct network are determined. The method of constant head loss is quite simple and is applied at the stage of feasibility study of ventilation systems:

Depending on the purpose of the room, according to the table of permissible air velocities, the speed on the main section of the duct is selected.

According to the speed defined in point 1, and on the basis of the design air flow, an initial head loss (per 1 m of duct length) is found. The diagram below is used for this.

The most loaded branch is determined, and its length is taken as the equivalent length of the air distribution system. Most often this distance to the farthest diffuser.

Multiply the equivalent length of the system by the loss of head from paragraph 2. To the obtained value, the loss of pressure on the diffusers is added.

Now, the diagram below determines the diameter of the initial duct coming from the fan, and then the diameters of the remaining sections of the network according to the corresponding airflow. In this case, a constant initial head loss is assumed.

Diagram of the determination of head loss and diameter of ducts

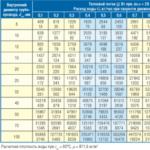

The diameter of the circular ducts is indicated in the pressure loss diagram. If instead of them ducts of rectangular cross-section are used, it is necessary to find their equivalent diameters using the table below.

Notes:

If space allows, it is better to choose round or square ducts;

If space is not enough (for example, during reconstruction), rectangular ducts are chosen. Typically, the width of the duct is 2 times the height).

In the table, the duct height in mm is indicated in horizontal, the width in the vertical direction, and in the cells of the table, there are equivalent duct diameters in mm.

When the duct parameters (their length, cross-section, friction coefficient of air against the surface) are known, it is possible to calculate pressure losses in the system at the designed air flow.

The total pressure loss (in kg / m 2) is calculated by the formula:

P = R * l + z,

where R is the frictional pressure loss per 1 running meter of duct, l is the length of the duct in meters, and z is the loss of pressure on the local resistance (with variable cross-section).

1. Loss of friction:

In a circular duct, the frictional pressure loss P p is assumed to be:

Ptr = (x * l / d) * (v * v * y) / 2g,

where x is the coefficient of friction resistance, l is the length of the duct in meters, d is the diameter of the duct in meters, v is the air speed in m / s, y is the air density in kg / m 3, g is the gravity acceleration (9 , 8 m / s2).

- Note: If the duct has not a round but a rectangular cross-section, the equivalent diameter must be substituted in the formula, which for the duct with sides A and B is equal to: dequ = 2AB / (A + B)

2. Losses on local resistance:

Loss of pressure on local resistance is calculated by the formula:

z = Q * (v * v * y) / 2g,

where Q is the sum of the coefficients of local resistance in the airway section for which the calculation is made, v is the air flow velocity in m / s, y is the air density in kg / m3. g is the gravity acceleration (9.8 m / s2 ). The values of Q are presented in tabular form.

Method of permissible speeds

When calculating the network of air ducts, the optimal air speed is taken as the initial data by the permissible speed method (see table). Then, the desired section of the duct and the pressure loss in it are considered.

Procedure for aerodynamic calculation of air ducts by the method of permissible speeds:

- Draw a diagram of the air distribution system. For each section of the duct specify the length and amount of air passing in 1 hour.

- Calculation begins with the farthest from the fan and the most loaded areas.

- Knowing the optimal air speed for a given room and the volume of air passing through the air duct in 1 hour, determine the appropriate diameter (or cross-section) of the duct.

- Calculate the pressure loss for friction P tr.

- According to tabular data, we determine the sum of the local resistances Q and calculate the pressure loss for local resistances z.

- The available pressure for the following branches of the air distribution network is defined as the sum of the pressure losses in the sections located before this branch.

In the process of calculation, it is necessary to consistently link all the branches of the network, equating the resistance of each branch to the resistance of the most loaded branch. This is done with the help of diaphragms. They are installed on lightly loaded sections of ducts, increasing resistance.

Table of the maximum air speed depending on the duct requirements

|

Appointment |

Basic requirement |

||||

|

Noiselessness |

Min. head loss |

||||

|

Trunk Channels |

Main channels |

Branch |

|||

|

Inflow |

Extractor hood |

Inflow |

Extractor hood |

||

|

Living spaces |

|||||

|

Hotels |

|||||

|

Institutions |

|||||

|

Restaurants |

|||||

|

The shops |

|||||

Note: the airflow rate in the table is given in meters per second

Method of constant head loss

This method assumes a constant loss of pressure on 1 running meter of the duct. Based on this, the dimensions of the duct network are determined. The method of constant head loss is quite simple and is applied at the stage of feasibility study of ventilation systems:

- Depending on the purpose of the room, according to the table of permissible air velocities, the speed on the main section of the duct is selected.

- According to the speed defined in point 1, and on the basis of the design air flow, an initial head loss (per 1 m of duct length) is found. The diagram below is used for this.

- The most loaded branch is determined, and its length is taken as the equivalent length of the air distribution system. Most often this distance to the farthest diffuser.

- Multiply the equivalent length of the system by the loss of head from paragraph 2. To the obtained value, the loss of pressure on the diffusers is added.

Now, the diagram below determines the diameter of the initial duct coming from the fan, and then the diameters of the remaining sections of the network according to the corresponding airflow. In this case, a constant initial head loss is assumed.

Diagram of the determination of head loss and diameter of ducts

Use of rectangular ducts

The diameter of the circular ducts is indicated in the pressure loss diagram. If instead of them ducts of rectangular cross-section are used, it is necessary to find their equivalent diameters using the table below.

Notes:

- If space allows, it is better to choose round or square ducts;

- If space is not enough (for example, during reconstruction), rectangular ducts are chosen. Typically, the width of the duct is 2 times the height).

In the table, the duct height in mm is indicated in horizontal, the width in the vertical direction, and in the cells of the table, there are equivalent duct diameters in mm.

Table of equivalent duct diameters

With this material, the editorial office of the World of Climate magazine continues the publication of chapters from the book "Ventilation and Conditioning Systems. Recommendations for designing for production

water and public buildings ". Author Krasnov Yu.S.

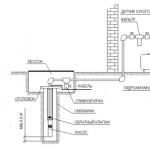

The aerodynamic calculation of the ducts begins with the drawing out of an axonometric scheme (M 1: 100), affixing the number of sections, their loads L (m 3 / h) and lengths I (m). Determine the direction of the aerodynamic calculation - from the most remote and loaded site to the fan. In case of doubt in determining the direction, all possible variants are calculated.

The calculation starts from the remote site: determine the diameter D (m) of the round or the area F (m 2) of the cross-section of the rectangular duct:

The speed increases as you approach the fan.

According to Appendix H, the nearest standard values take the form: D CT or (а х b) ст (м).

Hydraulic radius of rectangular ducts (m):

|

where is the sum of the coefficients of local resistances in the duct section.

Local resistance at the border of two sites (tees, crossings) is referred to a site with a lower flow rate.

Coefficients of local resistances are given in the annexes.

The scheme of the supply ventilation system serving a 3-storey office building

Calculation example

Initial data:

| No. of plots | feed L, m 3 / h | length L, m | υ rivers, m / s | cross-section a × b, m |

υ f, m / s | D l, m | Re | λ | Kmc | losses on the plot Δp, pa |

| the grating pp at the output | 0.2 × 0.4 | 3,1 | — | — | — | 1,8 | 10,4 | |||

| 1 | 720 | 4,2 | 4 | 0.2 × 0.25 | 4,0 | 0,222 | 56900 | 0,0205 | 0,48 | 8,4 |

| 2 | 1030 | 3,0 | 5 | 0.25 × 0.25 | 4,6 | 0,25 | 73700 | 0,0195 | 0,4 | 8,1 |

| 3 | 2130 | 2,7 | 6 | 0.4 × 0.25 | 5,92 | 0,308 | 116900 | 0,0180 | 0,48 | 13,4 |

| 4 | 3480 | 14,8 | 7 | 0.4 × 0.4 | 6,04 | 0,40 | 154900 | 0,0172 | 1,44 | 45,5 |

| 5 | 6830 | 1,2 | 8 | 0.5 × 0.5 | 7,6 | 0,50 | 234000 | 0,0159 | 0,2 | 8,3 |

| 6 | 10420 | 6,4 | 10 | 0.6 × 0.5 | 9,65 | 0,545 | 337000 | 0,0151 | 0,64 | 45,7 |

| 6a | 10420 | 0,8 | Yu. | Ø0.64 | 8,99 | 0,64 | 369000 | 0,0149 | 0 | 0,9 |

| 7 | 10420 | 3,2 | 5 | 0.53 × 1.06 | 5,15 | 0,707 | 234000 | 0.0312 × n | 2,5 | 44,2 |

| Total losses: 185 | ||||||||||

| Table 1. Aerodynamic calculation | ||||||||||

Air ducts are made of galvanized sheet steel, the thickness and size of which correspond to approx. N out. The material of the air intake shaft is brick. As the air distributors are used the grids are adjustable type PP with possible sections: 100 x 200; 200 x 200; 400 x 200 and 600 x 200 mm, a shading factor of 0.8 and a maximum air outlet velocity of up to 3 m / s.

Resistance of the receiving warmed-up valve with fully open blades 10 Pa. The hydraulic resistance of the air heater is 100 Pa (according to a separate calculation). Resistance filter G-4 250 Pa. Hydraulic resistance of silencer 36 Pa (according to acoustic calculation). Based on architectural requirements, ducts of rectangular section are designed.

Sections of brick channels are taken from Table. 22.7.

Coefficients of local resistances

Section 1. Lattice PP at the output section 200 × 400 mm (calculated separately):

| No. of plots | Type of local resistance | Sketch | Angle α, deg. | Attitude | Justification | CCM | ||

| F 0 / F 1 | L 0 / L st | f f / fst | ||||||

| 1 | Diffuser |

|

20 | 0,62 | — | — | Table. 25.1 | 0,09 |

| Retraction |

|

90 | — | — | — | Table. 25.11 | 0,19 | |

| Tee-passage |

|

— | — | 0,3 | 0,8 | Ad. 25.8 | 0,2 | |

| ∑ = | 0,48 | |||||||

| 2 | Tee-passage |

|

— | — | 0,48 | 0,63 | Ad. 25.8 | 0,4 |

| 3 | Tee-branch |

|

— | 0,63 | 0,61 | — | Ad. 25.9 | 0,48 |

| 4 | 2 branches | 250 × 400 | 90 | — | — | — | Ad. 25.11 | |

| Retraction | 400 × 250 | 90 | — | — | — | Ad. 25.11 | 0,22 | |

| Tee-passage |

|

— | — | 0,49 | 0,64 | Table. 25.8 | 0,4 | |

| ∑ = | 1,44 | |||||||

| 5 | Tee-passage |

|

— | — | 0,34 | 0,83 | Ad. 25.8 | 0,2 |

| 6 | Diffuser after fan |

|

h = 0.6 | 1,53 | — | — | Ad. 25.13 | 0,14 |

| Retraction | 600 × 500 | 90 | — | — | — | Ad. 25.11 | 0,5 | |

| ∑= | 0,64 | |||||||

| 6a | Confusor in front of the fan |

|

D r = 0.42 m | Table. 25.12 | 0 | |||

| 7 | Knee | 90 | — | — | — | Table. 25.1 | 1,2 | |

| Lattice grating | Table. 25.1 | 1,3 | ||||||

| ∑ = | 1,44 | |||||||

| Table 2. Determination of local resistances | ||||||||

Krasnov Yu.S.,