Repair chimney brick and steel. Repair of chimneys

Chimney is one of the main elements of the heating system of a country house. Chimney is necessary for the construction of a stove, installation of a fireplace and so on. In order for the chimney to last for a long period of time, it is required to regularly inspect it and eliminate the identified problems in a timely manner. Chimney repair can be done independently or with the help of specialists.

Preparation for repair

Repair of chimneys should be carried out as soon as possible after the malfunction is identified.

To determine the cause of the inoperability of the chimney, it is necessary:

- inspect the outside of the structure for cracks and damage;

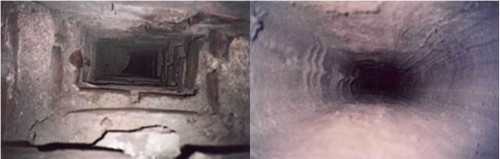

- to inspect the inside of the smoke channel. To do this, you can use a regular flashlight or a portable camera connected to a computer.

In most cases, the repair of the chimneys of the stoves is carried out on the roof of the house, so you should not forget about the safety rules.

The basic malfunctions of brick chimneys and ways of their elimination

Repair of a brick chimney should be carried out in several cases:

- clogged with soot or foreign objects;

- condensate is formed;

- cracks formed on the surface of the pipe;

- blowing occurs.

Clogging

The causes of clogging of the chimney can be:

- accumulation of soot;

- loss of bricks;

- collapse of the plaster;

- bird nests or other foreign objects.

Litter can lead to a reduction in thrust in the channel. To eliminate it, it is necessary:

- prepare a long rope, to the end of which to tie the weight;

- lower the device from the top of the chimney.

A heavy weight will help "break through" the chimney and the objects that caused the malfunction, fall to the heater.

If it is not possible to remove the blockage in this way, then it is necessary to disassemble part of the masonry, then remove the obstructed objects and restore the chimney channel again.

For elimination, you can use:

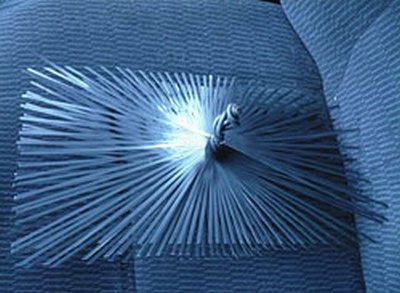

- ruff, tied to a long stick or rope;

- chemical preparations of the "Trumpet" log type;

- "Grandfather's" methods. For example, burning potato purification in a furnace.

More information about mechanical cleaning of the chimney can be found by watching the video.

It is recommended to check the chimney for blockages before each heating season begins.

If the examination of the chimney reveals the emergence of resinous spots or the impregnation of the channel with moisture, the reason lies in the formation of excessive condensate, which prevents the normal operation of the equipment.

Condensation may occur due to:

- insufficient insulation of the smoke channel;

- the formation of cracks.

In order to require mineral or basalt wool, which is attached to the chimney. Warming is carried out in rooms where there is insufficient heating of the room: in the attic, when passing through the roof and so on.

A large amount of condensate can lead to deterioration of the draft and the appearance of the smell of burning in the heated room.

The repair of a chimney from a brick often implies the closure of the formed cracks that may appear:

- because of the large temperature difference. For example, in the cold time, the furnace was not heated for a long time. The first flood results in a rapid increase in the temperature inside the furnace, while the outer part does not have time to warm up evenly;

- over time.

Cracks can lead to fogging of the room and the occurrence of a fire. Therefore, such a malfunction of the chimney must be eliminated immediately.

To eliminate small cracks, you can use:

- clay;

- sealant that can withstand high temperatures.

Troubleshooting is performed in several stages:

- the place where the crack formed was slightly widened. To do this, you can use a spatula, drill and other suitable tools;

- a hard brush removes the remains of mortar, bricks and other foreign objects;

- crack is filled with the selected material;

- the place of repair is processed by the material with which the whole furnace is covered (whitewash, paint, tile and so on).

To eliminate large damages, it is necessary to replace the chimney section. All work is done according to a scheme similar to the above instructions. Instead of clay or sealant used new bricks.

Blowout

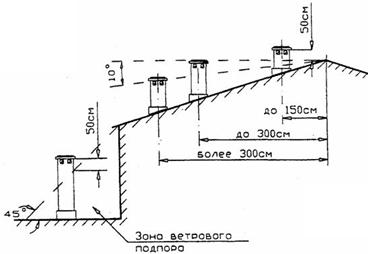

Blowing the furnace or the emergence of reverse traction can be caused by two most common causes:

- outage of the head. Chimney pipe repair in this situation is made by the simplest replacement of equipment;

- insufficient on the roof. In this situation, it is necessary to increase the length of the chimney by adding several rows of bricks.

Basic malfunctions of metal chimneys and ways of their repair

Repair of gas chimneys, as well as metal chimneys, is carried out if:

- the metal was rusted and its thickness decreased. Replacement of the damaged chimney section is required;

- out of order, preventing the formation of return draft in the chimney. The head is the part of the chimney most susceptible to the influence of atmospheric precipitation. Timely replacement of the head can prevent further destruction of the chimney;

- weakened the fastening of pipes to the wall. Replacing the fixing clamps and secure fixation of the pipe will avoid its deformation. If the pipe is already deformed, then a complete replacement of the damaged area is required.

Do not forget that a metal chimney, as well as a brick chimney, requires constant cleaning.

In the article the most common causes of failure of chimneys are given. However, periodically there is a need for additional works, such as:

- chimney painting. In most cases, whitewash is used to treat the smoke channel, but water-based paint may be used;

- anticorrosive treatment of metal surfaces;

- replacement of doors, fire bars and so on;

- repair of the furnace base.

Chimney is a structure that requires constant supervision of its condition. The simplest maintenance of the chimney is recommended to be done annually. Identified malfunctions, such as breaking brickwork or deforming a metal pipe, must be eliminated before the start of the heating season, as they can lead to a fire.

The range of works on the repair of chimneys is very wide - from complete dismantling, followed by the restoration of the chimney to small maintenance. The need for repair is caused by two main reasons: natural and artificial.

Natural causes are aging chimneys from time and aging moral, the destruction of chimneys under the influence of natural forces of nature. And, perhaps, there are no other natural causes.

Artificial causes are their overwhelming majority. They are based on the human factor, or simply sloppiness, illiteracy, greed and Russian pofigism. These reasons are valid regardless of the material from which the chimneys are made, or chimneys.

Here are the main ones:

● Substandard materials

● Wrong construction

●

● Unprofessional masons and fitters

● Non-compliance with standards

● Incorrect operation

Remaking improperly made chimneys requires more than proper construction based on the right design. If you still have to resort to repair, do not step on the rake again: call a professional chimney sweep. Our specialists carry out all types of works to bring chimneys, fireplaces, stoves, gas ducts, ventilation ducts into a workable state that meets all requirements and standards. We are responsible for our work, we give a guarantee, we carry out maintenance of chimneys, fireplaces, stoves.

All these designs, as well as your favorite car, require proper attitude and regular maintenance.

Expenditure on literate chimney installation will ensure your peace of mind when you use it and save you from the costs of rework.

Types of repair of chimneys

- Insertion of sleeves from certain

- Restoration of the destroyed masonry of the brick chimney. materials in the channel.

- Channeling the channels from the inside.

- Measures against icing of chimneys.

Restoration of the destroyed masonry of a brick chimney

The causes of the destruction of the brickwork of the chimneys are mainly related to the violation of the rules for the construction of chimneys:

- the use of bricks, not suitable for laying pipes,

- poor-quality masonry,

- exposure to condensate,

- absence or incorrect design of the protective umbrella.

If possible, a partial disassembly is carried out, followed by restoration of the masonry. Otherwise, the pipe must be completely disassembled, and the pipe laying is carried out again.

If it is not possible to disassemble the pipe or pass through the channels inside the walls, the root pipe is laid or the steel chimney is installed along the house.

Zagolzovka

Many of the problems that arise with chimneys can be solved with the help of zagilizovki - A new stainless steel pipe is inserted into the old brick chimney.

Confinement

Confinement - plastering channels from the inside using a Finnish fireproof Mordax mixture, which has an exceptional penetrating power:

- ● The channel fills all the slots,

- ● the surface is leveled,

- ● accordingly, the thrust is improved,

- ● the cross-section of the channel practically does not decrease.

This method is suitable for chimneys from fireplaces, stoves, solid fuel heating units, and also for ventilation ducts. You can mull the vertical channels of a sufficiently long length. Channels that have a small slope are also easily fused.

|

Repair of the chimney from the barbecue in the restaurant.Installation of this chimney was originally performed incorrectly. |

|

Repair of the head of the pipe from the furnace in the temple near Moscow.This is a single example of the natural destruction of pipes under the influence of time |

|

These pipes are found in elite cottages on Rublyovka. |

|

This cottage was made chimney repair, the insulation of the head and the lining of the headings of all pipes by the profiled sheet |

|

Repair of the head of a pipe, replacement of a flyvark on the roof of a house in Moscow |

|

Cottage near Zvenigorod. The crumbling pipes were treated with a protective solution, insulated and lined with a profiled sheet in the color of the roof. |

Our practice shows that in most cases it is caused by incorrect installation of chimneys or poor-quality brickwork of chimneys. The most interesting thing is that many owners of such incorrect chimneys like to step on the rake: they want to repair chimneys as cheaply as possible and trust these works to the same "experts" that this chimney was building.

However qualitatively nor was work has been done on the laying of the chimney, time does its work, and even the most reliable buildings can not withstand its influence. If the first pathological signs of deformation, shedding, cracking appeared, it is best to immediately take measures to eliminate them, otherwise the fatal destruction of the pipe will occur, and then it will be necessary to build it again. In other words, repair of a brick chimney becomes acutely relevant task.

Works on the repair of chimneys can be varied - from sealing small cracks and to dismantling the entire structure and erecting a new one.

The causes and consequences of destruction

To artificial destruction can be attributed: poor-quality illiterate masonry; low-grade materials used at work; improper exploitation; low qualification of the master-stove; non-observance of rules and schemes of erection of a structure.

In case of incorrect work in chimney a condensate can form in the pipe, and in the event of temperature changes and freezing of water, ice will rupture the solution in the masonry and destroy the bricks. After such processes, the thrust violation is not ruled out, and it means that it will be impossible to heat the fireplace or stove, since the smoke will not leave the pipe, but will go to the room.

When using poor-quality or non-hardened bricks, it can be spoiled by sparks or ignition of gases emanating from the furnace. In the future, these disruptions can lead to damage to the whole stove heating system or even to a fire.

Repair of the chimney from brick is made in and cases of its spoilage for other reasons - for example, due to the effects of spontaneous manifestations or mechanical influences, leading to a violation of the integrity and solidity of the masonry.

To natural causes of destruction include the aforementioned long-term use, and, as a consequence, the general aging of the structure.

Types of repair work

Works on the repair of chimneys are rather laborious, considering that part of the processes must be carried out at a sufficiently high altitude, in rather difficult conditions.

The technology of repair can be different:

- Dismantling, and then - the restoration of the masonry that fell into disrepair.

- Installation of shells made of special materials into the duct of the chimney.

- Internal lining of existing channels;

Each of these processes has its own peculiarities and complexities.

Masonry restoration

If the masonry is partially destroyed, then it is possible to replace the damaged bricks. They are carefully released from the solution and pulled out of the row. Next, clean the place and lay on a fresh solution of a new high-quality brick.

If the chimney bricks are destroyed more than 15-20%, it must be dismantled completely and start building a new one. Dismantling is carried out to a full range, and a new masonry is made from it.

In case of large destruction and impossibility to repair, the chimney is dismantled to the base and rises again from the new brick. If this is not possible, the chimney is arranged from a steel pipe.

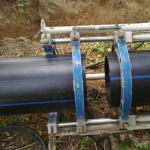

Installing the cartridge case

Another possible option for repairing the chimney is its voting, i.e. installation in the channel of a sleeve made of metal or ceramics.

Sometimes this process is performed immediately during the erection of the furnace, and in other cases - in the reconstruction purposes.

Positive sides of the installation of the sleeve:

- Chimney liners are made in round shape or square with rounded internal corners. Such forms favorably affect the efficient removal of combustion products, and do not allow condensate to be collected. Unlike round pipes, brick very often collect sediments and condensate in their corners.

- In addition, as another layer of the chimney, the sleeve reduces the heat loss of the furnace, as it increases the tightness of the chimney.

Preparation for work

Before starting the installation, it is necessary to audit the chimney:

- Check the condition of the masonry.

- Verify the reliability of the construction and the absence of obstructions in the channel where the sleeve will be installed.

- Next, determine the size of the pipe section to calculate the diameter of the sleeve for it.

- If there are obstructions in the channel, it is necessary to disassemble the part of the pipe in height so that it is easy to install the sleeve;

- Make room for work.

Installation

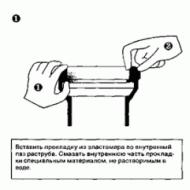

When everything is ready, you can proceed with the installation process.

- The first thing to do is to disassemble the masonry by releasing the channel for installing the cartridge case.

- The installed element must have dimensional parameters corresponding not only to the section of the pipe, but also to its height. In addition, you need to provide a door that will allow you to easily clean the chimney section.

- If the sleeve is installed through the top, it is pushed down in parts. First, the lower part of it is fixed to ropes and lowered to the desired level. Further into the lowered part of the sleeve, it is necessary to insert the next section of the sleeve. The masonry should be disassembled in the place of their connection, for their better binding. Thus, the entire structure is collected, passing through the entire duct of the chimney.

- Between the walls of the chimney and the installed sleeve, a small space should be formed, which is filled with non-flammable thermal insulation materials.

- After the work is completed, a metal umbrella protecting the chimney from dirt and moisture is placed on the top of the pipe.

- The last stage is the embedding of the brickwork in those places where it was dismantled to connect parts of the sleeve.

Channel lining

Masonry - is the treatment of the internal channel of the chimney with special mixtures, if you say easier - plastering the inner walls. With the help of this process, it is possible to bring the destroyed walls in order, making them sufficiently smooth, and to restore the chimney's operability.

Masonry is carried out with mixtures of "Masan" and "Mordax", which can very quickly, without time-consuming dismantling of brickwork, bring the channel into a functional form. The advantage of this technology can be considered that the section of the chimney does not become smaller, and all the work is done in a few hours. The non-combustible composition of the mixtures has good adhesion to any surfaces and can withstand temperatures reaching up to 900 and above degrees.

- "Masan" is a Russian development, it is made on the basis of perlite. Behind the whole period of its application (starting from 2005), it showed itself only on the best side.

- The mixture of "Mordax", manufactured by Finland, is made on the basis of granite chips. It is refractory and well lays on the surface. The solution is prepared by dilution with water to the required consistency of a dry composite "Mordax", mixed with lime and cement.

The works are carried out in the following way:

- First it is necessary to close the surface around the chimney so that the fumigating mixtures do not splash the roof.

- Next, the chimney channel is cleaned with an iron brush, from the broken parts of the brick and soot.

- Clearing the channel, it must be moistened.

- Further, using a special brush and a winch, perform lining.

- As the brush moves along the walls of the channel, a firing mixture is distributed.

- The brushing process is repeated three times, and after each coating, it is necessary to allow the applied layer to dry.

It should be clarified that, perhaps, not one but two brushes will be needed, since the chimney can have a different cross-section throughout its entire length, and the brush should have a size that corresponds to the size of the channel.

Video about modern technologies of chimney repair

All these methods of repair are good, if there is an opportunity to implement them. But if the amount of repair work is too large or the chimney has irreparable damage, the best option is to completely replace the chimney. And the most correct decision will be to invite an experienced, skilled craftsman to perform this work.

In a house where a fireplace is built or any heat generator is installed, it is impossible to do without a chimney. It is considered not just a working element, but an indispensable complex construction that is responsible for the microclimate in the room and the full work of the home. It is very important that the chimney is properly designed and always cleaned. It is also important to carry out its repair in a timely manner, otherwise problems with ventilation can not be avoided. How to understand that it's time to repair chimneys? What are the main reasons for it? How to correct the faults correctly? In this article, we will try to answer all the questions of interest. But first of all it is necessary to understand how important the chimney is, so first of all we will consider its functions.

The chimney is a vertical channel with a section of rectangular or round shape, built of bricks or made of special metal structural elements. It should have good thermal insulation, meet the requirements of fire safety, be distinguished by ease of installation, endurance, durability, aesthetics. Its main tasks are the removal of generating gases and smoke from the fireplace, stove, boiler or any other heat generator into the atmosphere, providing a full thrust, giving the design a special decorating look.

Any malfunctions in the chimney operation can lead to accumulation of combustion products in the room, cause problems in the operation of the heating system or fireplace, and lead to a disruption of the normal air circulation. In view of this, it is very important to constantly check the chimney and promptly eliminate possible causes that could cause it to malfunction. About them - in more detail.

Important functions are assigned to chimneys, therefore they must be repaired in a timely manner

In what cases can not do without repair

Possible causes that necessitate the repair of chimneys can be:

- destruction of their outer part as a result of the negative impact of atmospheric precipitation or other impacts, both natural and non-natural;

- cracks on the brickwork inside the room;

- poor draft caused by improper laying, clogging with soot, blockage of fallen solution or brick;

- gaps in the foundation of the furnace, formed during operation, as a result of not heating the walls of the fireplace or stove, even after a long fire;

- cracks or poor-quality sealing with a solution of the chimney seams.

It is important to remember that it is desirable to eliminate these reasons in a timely manner, choosing the best way to repair it. Its choice depends on the material from which the chimney is made.

The reasons for repairing chimney channels are many, the main ones being formed are cracks and collapses

We repair the steel modular chimney

Steel chimneys are distinguished by their reliability and endurance, long operating life and availability. They are modular systems, consisting of individual metal elements, connected together by clamps. Their repair is quite simple and fast: after cleaning and inspection of the entire structure, the main cause is identified, which has caused problems with draft or smoke removal.

Most often, the faulty work is explained by the cracks formed on the individual segments of the chimney. To normalize it and resume the full functioning of the entire modular system, it is necessary to replace damaged elements in its design. This work will not take much time, as it does not require dismantling the entire chimney. It will be enough to remove several of its sections (maximum three to four).

It is important to remember that during replacement of damaged metal segments of the chimney, it is necessary to be extremely careful not to damage the clamps and not to break the integrity of the entire modular design. Each constituent element must reliably be fixed to the other, otherwise smoke and gases will pass through the connections, which is highly undesirable.

Steel chimneys consist of several elements, therefore they are repaired very simply: by replacing them

We fix malfunctions of a chimney from a brick

If the repair of steel chimneys is done quickly and simply, then the repair of chimneys made of bricks requires a more serious approach. It can be performed in several ways and largely depends on the cause that caused the problems. When the working element of the heat generator is covered with cracks or collapsed, the brickwork is repaired.

The main task of the master in this case is to restore the damaged area as high as possible. To do this, it is necessary to disassemble the chimney to the site of its damage and re-execute the masonry using a new brick. If the chimney design is made correctly, during the repair it will not be necessary to disassemble the entire clutch. If mistakes were made during the installation of smoke and smoke systems, it is easier to completely redo it.

It is very important: during the repair of a brick chimney, only chamotte clay used for laying fireplaces and stoves, and fireproof bricks can be used.

Repair of brick chimneys can be carried out in several ways, the choice of the concrete largely depends on the reasons that caused the problems

When the alteration of a brick mine is required, the chimney is made into the chimney. This method of repair will help to avoid laborious and dirty work, which subsequently leads to the need to repair the roof and the entire room, is used only when problems arise with straight, without bends and displacements, a chimney, involves the installation of a ceramic or steel tube of a certain diameter, corresponding to the needs of the heat generator. The result of the chimney liner is an improvement in thrust, an increase in the tightness of joints and joints, and the prevention of formation of soot on a smooth surface.

Important point: it is better to use stainless steel pipes for the chimney liner. They react steadily to temperature fluctuations and condensate effects, so they will last much longer.

If it is necessary to repair the chimney quickly and efficiently, it is best to resort to its lining. This method does not involve masonry analysis. It is based on finishing the chimney with special refractory compounds made of granite chips, cement and lime or rocks of perlite, characterized by high adhesion to brick and concrete surfaces.

Clamping of chimneys with the help of Mordax mass

The main features of chimney lining are:

- versatility: this method can be used both for repair of chimneys and ventilation ducts;

- improved traction and simplified cleaning of the channel due to the formation of a smooth surface inside the chimney;

- resistance to temperature and weather conditions;

- minimum labor costs for repair work;

- increased fire safety and a minimal risk of leakage of combustion products due to the monolithic nature of the internal surface of the chimney;

- the speed of the process (this will take a maximum of five hours to repair the chimney);

Important: after the chimney is chimneyed, the area of its chimney is practically unchanged.

The process of chimney channel lining begins with preparatory work. First of all, it is cleaned of soot, separating pieces and debris, then moistened with a special aqueous solution and with a blowing brush wrapped in a cloth, which is flushed down the chimney, a special composition is put in three layers. It is important not to forget that each successive layer should be applied after the previous one has completely dried.

Flue liner with polymer liners

Another effective way of repairing brick chimneys is the lining of polymer liners. Despite the fact that he has not yet gained a special popularity, experienced masters recommend to resort to it in the course of the work. Lining of polymer liners involves the installation in the chimney channel of special polymer liners, developed by the new technology. They not only allow to quickly restore the chimney, but also minimize the risk of its further destruction.

Repair of the chimney channel in this way is performed in this way:

- the polymer liner is pumped with compressed air, then with steam and mounted in the internal channel of the chimney;

- under the influence of pressure, the liner takes the form of a chimney channel, tightly adheres to the walls and freezes, as a result - a smooth and durable polymer layer without seams and cracks is formed inside the chimney, resistant to atmospheric precipitation and high temperatures, it does not accumulate soot and condensate.

The maintenance of the chimney, repaired in this way, is quite simple and is done quickly.

Polymer sleeve will save a brick chimney from destruction

No matter how quickly and easily the chimney is not repaired, it is advisable to place it on the shoulders of experienced professionals. They will cope with the task qualitatively and as correctly as possible.

In the country houses, in cottages the main source of heat is the stove. Therefore, it is important that it is always in good order. Quite often, malfunctions in the operation of the furnace are due to a disturbance in the thrust. In this case, the repair of the chimneys, which is ready to carry out the company "Black Cat 03", is needed.

Responsible and professional repair of chimneys

deterioration of traction can cause pieces of brick, mortar, falling into the chimney passage. Also, a thick layer of coal can cause a thick layer of soot on the inner surface of the chimney. Our specialists will clean such ordinary soot with the help of a special panicle. If the soot is resinous, it must be burned with fire, diluted in the cleaning hole. In the fuel when burning soot, add substances that carry out the combustion of a large amount of soot.

One of the vulnerable parts of the furnace tube, which often requires repair, is a headpiece. It can collapse under the influence of wind, precipitation, with changing temperatures. A head that has become unusable can become a prerequisite for the occurrence of a fire. Therefore, it is so important to repair the chimneys in time. Masters of the company "Black Cat 03" are ready to repair the head. For this purpose, the destroyed part of the pipe is preliminary disassembled, the clay solution is removed. The rest of the pipe is impregnated with water, and then the masonry is laid on the cement mortar of the baked brick. Also, our specialists, if necessary, fill up cracks, empty stitches of the chimney. "Black Cat 03" will be happy to cooperate with everyone!