Make a swing with your own hands from the profile pipe. What swing functions can perform. Selection of materials for the manufacture of swings

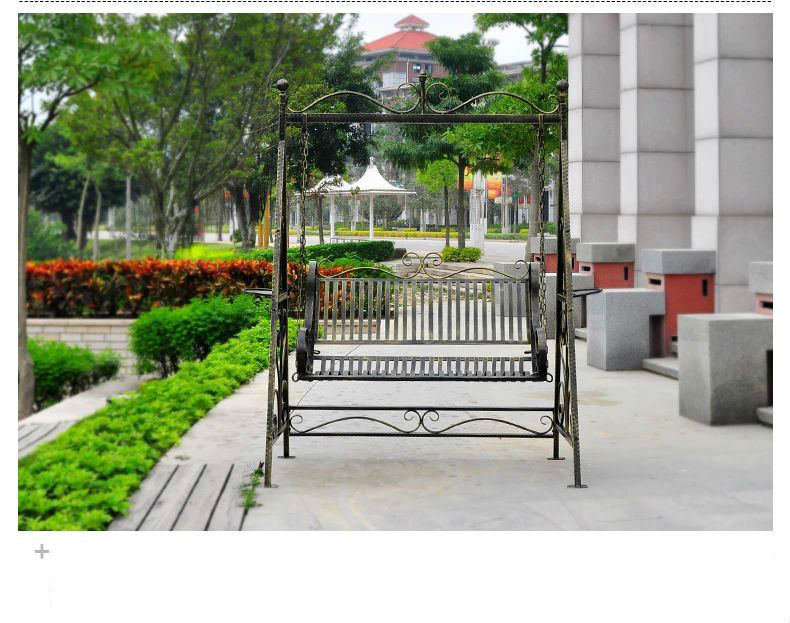

Oh, how I do not want to leave the shady garden on the afternoon siesta on a warm summer day in a stuffy house. Well, why not relax on a light breeze, admiring the way he playfully plays with foliage? And really, why? After all, there is also a very comfortable option for this and his name is a garden swing made of metal. Today they are very popular with summer residents and owners of cottages. Designs can be assembled on their own or purchased in ready-made form. In the first case, the swing will be a kind of confirmation of your talent, because in the homemade, you can express all the originality of your imagination by assembling the design in an unusual form and providing an unprecedented decor.

garden swings, as an integral attribute of any home or villa

There are a lot of options and ideas for the design of the swing, so the homebrew master does not have to reinvent the wheel, you can simply modify the existing models.

Types of garden swings

Swings for the garden are divided into two types:

- Portable.

- Stationary.

stationary garden swing. made of metal

Portable options

Mobile swings are fairly stable. They are simply mounted, easy to move and easy to transport. To ensure that the structure does not overturn during operation, it must be given maximum stability. This is done by selecting an equal area and fixing the legs with reinforcement pins. The latter is easy to extract from the ground if necessary to move the swing to another place. Sometimes the metal structure is welded, fixing the junction of the crossbar with the supports with peculiar triangles. In this way, it is given additional rigidity. Portable models are also convenient because they can be removed for winter period in a dry place, so it's not necessary to stand around and rust.

small swings with a metal rack and a comfortable soft sofa

Stationary options

These constructions are put thoroughly. Their supports deepen into the ground and are concreted. Usually, such swings are put on spacious plots. The instruction for their operation provides for a few meters of free space both behind and in front of the device.

Garden swings made of metal in various variations

Swing bench

design swing-bench with a curtain

Classic assembly with suspension of seats on rigid rods or chains. As for the creation of supports and everything else, here, if you are ready to collect all this yourself, you are free to enter the zone of creative search. This is simply necessary to do, as looking at the projects of standard models you will realize that simplicity, in the case of swings, is by no means synonymous with comfort. To sway on such a copy and get pleasure from it will be possible only in quiet and dry weather: rain and wind will disturb the idyll of relaxation, as in the complete set there are no roofs and side fences. This explains the high popularity of models with canopies, canopies, as well as soft seats, which will not be superfluous if it is about convenience.

Forged swings

forged metal swings will be a real work of art in the garden

The presence of a welding machine and high-quality iron will make it possible to create a masterpiece. Swings of this type are incredibly durable, powerful and with proper care ready to serve for centuries. Beauty combined with durability makes them a priority of choice. The design has a wide base and an all-welded suspension. Mounting suspension is also done by forging, no springs. But the roof is better made of polycarbonate than metal. It softens and muffles the sound of rain, and from the sun, so will not repent. Unbelievably aesthetically, almost magically, look like forged swings, decorated with intricate steel ornament and beautiful lamps.

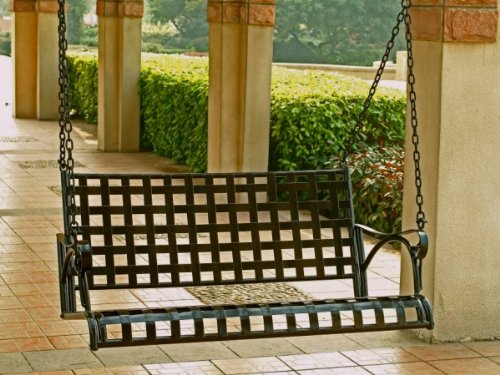

Sofa-swing

massive sofa-swing for three people

"We can safely say that the metal structures will look great in the ornate forging and wood trim"

This kind of swing can be found in almost every second garden. They are chosen for their compactness and convenience. Soft blocks with which the seat is covered can be removed and folded. The model itself is quite maneuverable, so it is often moved to covered terraces and verandas during the winter. Many designs have a folding in a horizontal plane seat.

To manufacture the sofa-swing there are metal pipes and profile. If you are going to buy a finished product, then be sure to look at how many swinging it is calculated, how many positions are provided for the backrest, whether it is possible to convert it into a spacious bed.

sofa-swing in the gazebo with the columns will convey the spirit of classicism

Naturally, I would like to see in my garden a design under a white tent and surrounded by fluttering curtains, but such a dream is worth serious money. Look at more budgetary options: they, often, are no worse.

If we talk about the decor of the swing, then we can safely say that the metal structures will look great in the framing of florid forging and wood plating. Canopies and canopies must be fastened low, wide and do not forget to give them a slight inclination, so that the rainwater drains back. If a night sleep is planned on the swing, it makes sense to hide the construction under the mosquito net.

compact portable sofa-swings

You can arrange a swing translucent curtain. Its task will be not only decorative. It will dissipate bright sunlight and protect you from sudden gusts of wind. Nobody forbids to show imagination and, for example, to add to the decor with gentle sounding bells or unusual light effects. In this regard, everything can be in full accordance with your wishes.

We build ourselves

What should be considered when designing the arrangement of a garden swing made of metal?

a single design solution: a swing and a table. complementing each other

Small rockery, large rocker

Engaged in assemblygarden swing made of metal, do not be lazy to make a separate single option, if the house has children. They will be much safer and more interesting to swing on a personal rocker, and adults do not have to wait for the child to play on their territory.

children's metal swing

For the child's design, a swing will require four curved profile pipes and a central cross member. The seat can be hung on a thick cable or chains. To increase the usability and safety of the child from falls, it is necessary to weld the back to the seat, after which it should be lacquered with lacquered wooden racks.

small metal swing with decorative forging

For adults, a more thorough construction of one and a half or two-inch pipes is being built. Of these, support sidewalls are made, reinforced with spacers at the bottom. On the upper crossbar, cut holes for the eyes or weld a pair of steel bearing clips to the pipe. This will firmly fix the seat.

Why is it better to build a swing made of metal, especially stationary ones? Because this material is much cheaper than a tree, it does not need complicated maintenance and only a welding machine is needed to create them.

stationary sofa-swings in the flower garden: a great place to relax

Unusual offers

"Amazingly cozy is a symbiosis of a hammock and a garden swing"

Lovers of originality can enjoy a garden swing made of metal in an unusual design. For example, the traditional seat-bench can be replaced with a comfortable metal chair-cocoon, fixed to the support post by one point. The amplitude of rotation and rocking in this model is not limited to anything. You can even rotate around your axis.

Unusually it will look like replacing the standard seat on the beach chaise longue. Especially interesting interpretations can be obtained by defeating the shape of the support.

metal swing-chair in the Art Nouveau style

Stunningly cozy is a symbiosis of a hammock and a garden swing. There will be no backs in the fabric seat, and it is not required, because in a hammock it is convenient to sit or lie down without it. A great idea for those who like to take a nap in the garden.

Hanging the seat on a single chain, instead of the standard two, you get an installation such as a swing chair.

An openwork metal chair can be attached, not philosophising with supports, to a strong branch, with a rope used as a suspension. By this you will demonstrate to the world that the comfort of sitting is important in the swing, and not the way of fixing it.

portable swing attached to a tree

The next version of the design swing invented by all appearances great lovers to eat in nature. In the bench seat, they mounted a small table, on the surface of which you can place drinks and desserts. For full comfort under the feet were installed support pads, which allows a cozy nestling for a long conversation.

To swing for a long time

In order for the garden swing of metal to serve for a long time, it is necessary to operate the products adequately and according to purpose.

- Do not under any circumstances exceed the maximum load indicated. Do not bog down on the swing of the crowd, but spread evenly over the length of the seat.

chair-swing complements the design of a furniture set

- Do not allow shock loads, which include a sharp sitting. This negatively affects both the fixing mechanisms and the stability of the structure as a whole.

- On a swing it is forbidden to jump. It is dangerous for them and standing swaying. Rigidly fixed seating should not be tried to swing aside.

- Too great amplitude of rocking is fraught with the quick failure of the connecting mechanisms of the structure. Since the seats are sometimes not too deep, in the sofa laid out before the sofa, there is no backrest at all, a strong swing can lead to the fact that you just drop to the ground and well, if from a small height.

glass swing with metal rim - non-standard solution for home and cottages

- The new element of garden design will require appropriate care, consisting in the timely cleaning, lubrication of mobile connections, rubbing, painting, replacing worn out parts.

Conclusion

Install a garden swing made of metal - a simple task and not too expensive. Their design is simple, but reliable. They may well serve more than one generation of your kind, of course, with the appropriate attitude towards them, So think about it, it may be time to equip you with a rest area on the countryside, and not plant everything with potatoes?

Photogallery: garden swings from metal

![]()

Video

Swings made of pipes, made by themselves, are 2-3 times cheaper than those sold in stores. This is a fairly strong argument for the owners who are determined, who have decided to improve the landscape of the garden plot on their own. However, to do this is not so difficult as it seems at first: it is enough for a couple of free evenings, a small amount of money for the purchase of materials and desire.

Before starting work, it is necessary to determine the model of the future swing, with the material from which the supports will be made, as well as with the version of the seat. This article presents the swing drawings of pipes with a wooden base. The frame for the seats can be anything - from a carelessly wrapped warm blanket to tailored to the size of soft cushions of dense fabric. It is assumed that these swings will be installed inside the gazebo, and therefore they do not have a roof.

Selection of materials for the manufacture of swings

Metal swings must withstand heavy loads, and therefore preference should be given to reliable and durable materials. So, the children's swing, capable of withstanding up to 200 kg, is made of profile thick-walled pipes with a section of 40x40 mm and a thickness of 1 mm.

To produce a swing from a profile pipe capable of withstanding three adults, pipes 7 cm in diameter and 2 mm in thickness will be required. Such pipes will be optimal for the manufacture of supports.

By increasing the diameter of the pipes and their thickness, it is possible to increase the stability of their construction to the loads: the larger the diameter and thickness of the tube, the greater the load it can withstand.

In addition to the pipes, a plywood or a thick board will be needed - to make the seat base. If the unprocessed board is used for the seat, it is pre-treated with a planer. However, the purchase of plywood and boards can also be saved by using old chairs, countertops or doors. In addition to wood, a rigid metal mesh or a base of plastic pipes can be used to make the walls.

In case the swing will stand outside the arbor, it will be necessary to build protection against precipitation and sun. To do this, on four sides of the swing, it will be necessary to bury four pillars, and on them to weld a rectangular base for the roof. As a roof can be used wood, cellular polycarbonate, metal or slate. If desired, the canopy can be attached to the supports holding the swings of the swings.

Necessary tools and materials

Now let's look at how to make a swing from the pipes yourself. First of all, you need to purchase the necessary materials and prepare tools. Select pipes in accordance with the drawings below. Dimensions of the swing can be changed both in length and width, provided that the overall proportions of the structure are maintained and the thickness of the pipes is increased.

List of required materials:

- Two steel pipes with a length of 6 meters of the same diameter.

- Eight metal corners.

- Two steel arcs (for example, from reinforcement) with a diameter of about 15 mm and a length of 25 centimeters.

- Two wooden canvases (even old window shutters, doors, countertops, chairs, etc.) can come up.

- Two cuts from a furniture cloth (under the size of the basis for a seat).

- Two zippers for making a cushion on the seat.

- A strong rope for mountaineering, capable of withstanding more than 300 kg (or chain).

- Special fastening clamps for repsnura (climbing cord).

- Welding machine.

- A hammer.

- Vice or pliers.

- Pencil or marker.

- Hacksaw for metal or a Bulgarian with a disc for metal.

- Building level.

- Roulette.

- Enamel for painting metal pipes.

This is all you need to make a garden swing with your own hands. From the pipes you can make not only a swing, but a canopy for them, if necessary. In this case, additional pipes and roofing material will be required. You can read about how to make a canopy of pipes and a shower curtain with your own hands.

Also, you should take care of the filling for the seat. In this case, preference should be given to synthetic materials that are resistant to changes in temperature and humidity (for example, sintepon or foam rubber).

Save on the furniture canvas, replacing it with old thick curtains or coverlets. Preference should be given to synthetic breathable or natural cotton materials.

Preparatory work

Before proceeding to the assembly of the swing, cut the pipes to the required length according to the drawing.

Details for the construction of supports

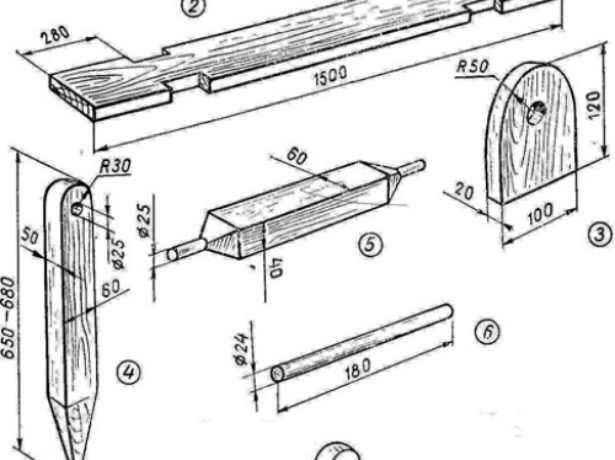

Swings are a construction of a rectangular base of 2 by 1.5 meters and small triangles on two (shorter) sides of this base, connected by a crossbar. On the crossbar there are attachments with a seat. For the construction of supports you need to saw:

- 3 long sections (two - for lower transverse supports and one - for the upper crossbar) to 2 meters;

- 4 medium segments (for vertical inclined supports) of 2.2 meters;

- 2 short segments (for the side parts of the base of the swing) at 1.5 meters - you can do without them.

Details for the construction of a seat

The design of the swing seat is two rectangles connected at an angle of 100 degrees. To make a seat you need:

- 3 metal pieces (for horizontal supports from the top, bottom and center of the seat) 1.6 meters long;

- 3 pieces (for vertical support of the seat back) 0.88 meters long;

- 3 pieces (for vertical supports of the bottom of the seat) length of 0.5 meters.

Mounting parts

The fixtures in these swings are two hinges of reinforcement welded to the upper crossbar. In the hinge, fixing hooks for the climbing cord are inserted, which will hold the garden swings from the profile pipe. Weld the fittings to the crossbar in advance.

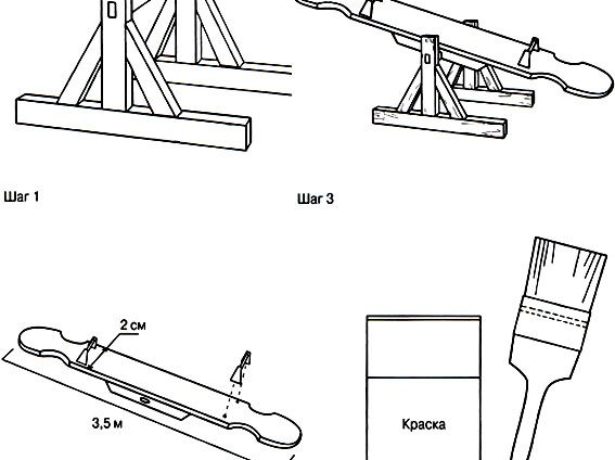

Assembling the swing

Before you weld the swing from the pipes, you should prepare the pipes themselves: remove rust from them and take a chamfer at the welding places. When assembling, it is recommended to follow this sequence:

- Measure and mark the welding spots on the corner pieces. In these places, the pipes should be chamfered at an angle of 45 degrees.

- Welding of pipes is carried out according to the planned scheme. The first thing is to build a rectangular base. To do this, two long and two short pieces of metal pipe are simply welded together, forming a classic rectangle.

- Welding details, you should carefully check their location with the help of a building level: to ensure that the angles of inclination of each pipe are met.

- Then, on both sides of the rectangle (along its short sides), vertical supports forming a triangle are fitted.

- Between the vertices of the triangle, a crossbar is installed with the rope (or chain) fasteners fixed to it.

- The foundation is ready. You can proceed with the assembly of the seat. The first thing to do is to weld the bottom of the seat - it is a classic rectangle with sides of 660x1600 mm and an additional stiffener in the middle.

- Then the backrest of the seat is assembled - in the form of an inverted letter S. With the welding machine, the backrest is welded to the bottom at an angle of 100 degrees.

- If desired, the seat can additionally be equipped with handles, holders for drinks, a folding table.

- During the assembly of the seat, provision should be made for the holes for the anchorages.

- The resulting structure is strengthened with metal corners. Metal corners are welded to each corner of the structure: 4 at the corners of the base, 2 - at the top of the triangular supports, 2 - at the top of the day of the seat.

- After welding, all details of the future swing are covered with paint or enamel for metal.

- The connection between the seat and the frame is carried out with a strong strap (or iron chain) and steel hooks. In order for the rope not to "ride" in the hinges, it will be necessary to fasten it with clamps.

- On this the main part of the work is done, the garden swings from the pipes are almost ready. It remains only to prepare a mattress for the swing.

- To make a mattress for a swing, you need to sew 2 large flat cushions 880x1600 mm (for the back) and 500x1600 (for the day) and a thickness of about 10 cm.

- Each of the pillows is desirable to provide lightning - this will avoid problems with cleaning.

- On the perimeter of the pillows, you can sew rope tails - with their help it is convenient to fix the mattress to the base and remove it if necessary.

In the absence of a canopy above the swings, it will be necessary to cover them from rainfall in rainy weather. To do this, a piece of polyethylene film or a cover for the car will fit.

It is assumed that the presented model will be stationary, and therefore its movement from place to place is impossible - it is too heavy. Therefore, the place for the swing should be identified and prepared in advance. It should be level - that the base lay on the ground, adjoining to it on all perimeter.

In some cases (when the surface of the earth is too uneven) it will be necessary to prepare for the swing a concrete or wooden pedestal. Alternatively, the ground under the swing can be leveled, and then reinforced with a plastic base. Install a swing metal from the pipe preferably in the shade - under the tree crowns, in the gazebo or under any other canopy. This will avoid direct sunlight, snow and rain, and therefore prolong the life of the swings.

To visually imagine how to make a garden swing with your own hands from the pipes, you can watch the video instruction.

For the arrangement of the suburban area, except for the garden, kitchen garden and the house, it is necessary to provide entertainment for children. The easiest way is to learn how to weld a swing with your own hands from metal pipes. Below are considered options for simple swings from pipes. They can be done in one or two days, provided that you have the skills of owning the instrument. How to make a swing using the minimum amount of materials? Here are some types of simple designs.

Metal swing is a good addition for your dacha or country house.

The first and most common type of self-made variants are welded from the metal tubes in the form of the letter "A", connected by a crossbeam. To her a synthetic cable or rods of metal with hinges joins the seat.

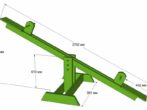

The second type of swing from the pipes is a long wooden bar with seats, swinging on low racks. Supports are made in the form of steel (from pipes), concrete (columns with a metal crossbeam) or wooden racks. In the simple case, such a structure works under the influence of gravity, and in more complex versions it is a swing on the spring.

- it is cheaper than wood and more wear-resistant;

- does not require complex care;

- the designs of metal pipes are very technological: in order to make a swing of pipes, only a welding machine is required.

Of what it is necessary to do the construction

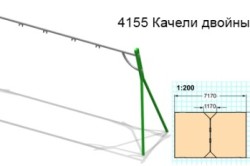

Figure 1. Drawing of double metal swings.

Before you learn how to make a swing, you need to start by purchasing the materials. For this, the following materials are purchased in the construction market:

- steel tubes in caliber not less than one and a half inches;

- metal profiles with a square section of 10X10 millimeters;

- metal corners (thickness 3-4 mm);

- copper wire;

- bolts and nuts;

- steel bars with a caliber of 8-10 millimeters:

- concrete mixture;

- seat (board, steel sheet, etc.);

- a cable synthetic, it is possible to apply and tow from the car;

- metal tube caliber not less than 50 millimeters;

- paint and primer.

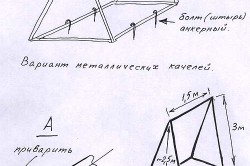

The manufacture of the swing begins with the assembly of the supports. They are triangles without a base with a crossbar in the form of the letter "A". At the top of them there are metal plates (Fig. 1).

The length of the supports made of pipes is 3-3.5 meters. The cross member is made of square sections, its length is about 75-80 cm. These parameters are adopted to ensure the most rigidity of the structure. If you yourself are too lazy to cut metal, then, buying pipes in the market, ask the seller, cut them to you in the right size.

The connection of the two bearing supports is carried out by means of a plate to which they are welded.

This part should be wide enough and thick enough to withstand the load.

Figure 2. The scheme of fixing the garden swing with metal corners.

A hole is drilled in the plate for a long bolt.

From it cut off the hat and drill it and the pipes of the supports through and through. From the top of the triangle, retreat 55-70 mm. Then the bolt and the supports are fastened with nuts. Should remain its end, which is inserted into the hole on the plate and clamped with a spanner using a nut of suitable diameter.

At a distance of 2.1-2.3 meters from the top of the triangle to the supports, a cross-member of a square profile is welded. Such beech "A" you must have at least two (for single swings) and three if the design is double.

Now you need to determine which seat to use for your swing. If this is purely a children's option, you can make a fixed single seat, and if you plan to use them for rest of adult family members, then you need to provide a variant of its replacement in a double seat.

First, select the material. Usually this tree. Use pine slats with a thickness of 30-80 mm, tied with furniture bolts. This allows you to remove the seat for the winter or to replace it with another.

The transverse beam connecting the triangular supports is made of a large diameter pipe (50 mm and above). It should be taken into account that the longer the length of your swing horizontally, the greater the caliber of this pipe. It is welded to the supports with the help of metal corners (Fig. 2).

Before you understand the design features of the garden swing, you should find out which type is more suitable for the suburban area. They are of 2 kinds - portable and hanging. From the names it is clear that the last option (the most common) is the seat + "rope", which is fixed on some stationary crossbar. Most often this is a fairly large branch of a tree. From a practical point of view, these models are not suitable for dachas.

Firstly, if it is a garden plot, then the trees are only fruit trees. Hanging on them "rocking chair", especially with metal elements, will not work.

We choose the material

The fact that the design is metal is understandable. But here's what? Pipes made from "durali" are light, inexpensive and are handled well. But there are 2 things to consider. First, strength. With considerable load, the parts will begin to deform. Secondly, all the connections will have to be made only prefabricated / collapsible, since it is unlikely that anyone will be able to fasten them with welding at home.

Storage conditions

The garden plot is not a courtyard, on which there is a large annex to the house, and a garage and a barn. What to do with the swing, when will the summer season end? Keep it open or disassemble and store? In the latter case, where? On the site or exported (although this few will become engaged)?

In view of all these features, the material is selected, as well as the design of the swing. It can be made monolithic or demountable. In the latter case, to what extent - completely or partially?

Features of engineering solutions

Supporting part

Here are a few schemes:

If the legs are exactly such, then you need to provide for the installation of "shoes", which will prevent the immersion of some part of the support in the ground and, accordingly, the swing of the swings. As an option - weld to the plates of the pins, which will add the entire structure of additional stability. Or, preliminarily fix the anchor on a concrete pad, on which the swing supports after installation will be fixed.

"Suspension mechanism"

Most often, hooks or rings are used for this. But there are some other, original solutions. For example, this is it.

In principle, also hooks, but the bench holds more evenly, and its possible distortions are kept to a minimum.

Canopy

It is not difficult to make it easy by installing a supporting frame in the upper part of the frame.

It can be made from a corner, a pipe of a small section, a thick wire. What to use - an oilcloth, a dense material, - is decided by the owner. The choice of options is huge.

- For hanging "bench" it is more appropriate to use chains. They are much more durable than the cable (even metal), and from the aesthetic point of view it is preferable.

- The minimum size of the swing support area is 2.5 x 1.5. In this case, regardless of their design, adequate stability will be ensured.

What do children do in their spare time on the street? Run and play, build a house of sand, ride a bicycle, drive a ball. And many more kids enjoy spending time on the swings. They are very fond of going up and dropping sharply. Such a swing can be done with your own hands, using for this purpose an improvised material.

- 1 Types of children's swings

- 2 Preparatory work

- 3 Step-by-step instruction for the manufacture of a hanging swing with a chain and a wooden seat

- 4 How to make a swing-balancer for a child from a tree with his own hands

- 5 Video: how to make a product from tires

- 6 Decoration process

Kinds of children's swing

Swings perform a number of useful functions:

Children are very fond of swinging on the swings

For several centuries, the swing remained a popular attraction, not only for children, but also for adults. No folk festivities in Ancient Rus could not do without the "flights" on these devices. In the times of the Russian Empire, they were both among the poor layers of the population, and among the rich people. Naturally, they looked differently: the poor were swinging on ordinary wooden boards tied with ropes to the posts, and the swings of the rich were decorated with decorative elements, pillows, bows and ruffles. In our time, interest in them is not quenched, they can also be seen on courtyards, in many children's organizations, in suburban "residences."

Which material is suitable for making yard swings

A swing can be done with your own hands, using almost everything that is at hand.

Table: Advantages and disadvantages of different materials

| Type of material | Benefits | disadvantages |

| Tree |

|

|

| Metal |

|

|

| Plastic |

|

|

Photo gallery: types of swings by material

Wooden swings require careful antiseptic processing and surface grinding

The strength and reliability of structures from metal no one disputes

Plastic children's designs can be bought ready-made, but they are suitable only for kids

Use of non-standard materials

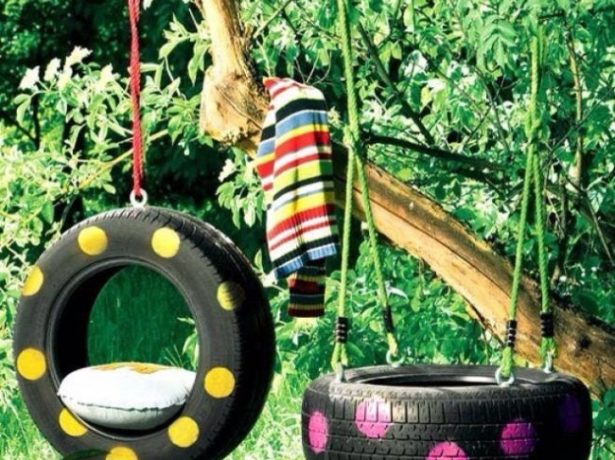

Some craftsmen can make swings from other materials, using for this purpose automobile tires, plastic pipes, wooden pallets, etc. Even snowboard boards, skateboards and other non-standard materials, for example, an old basin can go to play.

Photogallery: creative seats

The creation of a hanging swing does not take long

In skilful hands even a snowboard can be a useful element of children's swings

Older children like non-standard solutions, for example, a swing from a tire

The seat can be played by an old capacious pelvis

Swing constructions

According to the design features swings are:

- wireframe;

- suspended;

- floor;

- transformers;

- electronic type.

Age preferences for swing frame type - children from 3 to 10 years. Such facilities have a great advantage - mobility. They can be placed in any area of the suburban area or playground. They are strong enough to withstand the weight of children of primary school age.

Suspension swings are attached to the beam-crossbar. For this you can use chains, ropes, ropes. Their reliability increases with the use of a strong crossbar and on condition of competent fastening.

Floor constructions can be used for children under 5 years. Most often, when they are created, plastic and metal parts are combined.

For very young children can make a rocking chair-transformer, which combines several elements at once:

- chair for babies;

- mini-armchair;

- directly to the rocker.

The modern world can not be imagined without electronics. There are swings, equipped with a special system, which can include:

- timer;

- "music Center";

- device for setting the rhythm of swing movements.

They should be purchased only if your family has a newborn baby.

Photo gallery: different swing designs

Skeleton swings 0 habitual type of structures

The design of the full swing provides for their transfer to any suitable place

Good and convenient for children in hanging swings with back

Electronic swings, even crumbs

What swing functions can perform

Swings, despite the similar functions, may differ slightly from each other. This is connected with the design of these structures, and with their principles of work.

Which adult does not remember such attractions as boats? This type of swing can be used to entertain both children and their parents.

How cool it is to soar to heaven, swaying on "boats"

There are several types of children's structures, designated by one concept - swing-balancer. To such devices it is possible to carry a swing:

- "Libra";

- "pendulum";

- "Rocker".

Such fun fun is suitable even for small children. With the support of an adult on the swing can go and a one-year-old baby.

![]()

On the swing-balancer, you can ride only two

Nowadays, the manufacturers of children's facilities offer a rich variety of spring devices for rocking with balancing.

Of course, the swing can be purchased at the store, but it's better to work hard and build a swing by yourself. Years will pass, but your child, already grown up, will necessarily remember the minutes of "ups and downs" on the swings that you made with your own hands.

Photo gallery: spring constructions for babies

"By the seas, by the waves" - the design motto for children in the form of a boat

Sitting on an airplane, you can feel like a real pilot

Such a ladybird will not take your child to heaven, but fun will help

Springs, sitting in the helicopter, like all the kids

Preparatory work

If you decide to build a children's swing yourself, then you should do the preparatory work:

- determine the type of the future design;

- refine the parameters;

- draw a drawing;

- purchase the necessary materials;

- get all the necessary tools.

Material selection

The simplest design of the swing is pendant. You can make them completely wooden or combine different materials. For suspension elements, metal chains, ropes, strong cord, parachute slings or rope are most often used.

With through holes in the crossbar will need special fasteners

For attachment, you can use special tools.

To fix the swing with the girth of the rails it is possible with the help of special carbines

As a seat, it is best to use a polished board, since it is comfortable, does not crack in the cold, will not give the child discomfort in the heat and cold. It is possible to apply improvised means - old seats from chairs, armchairs, etc.

As a seat, you can use a broken chair

If you have more than one child or you often have guests with children, you can make a balance for two. Make them from different materials. The advantages of a metal swing are in their strength, but for the self-construction of such a construction a good welder will be needed. A swing made of wood is made easier, and they are less dangerous when used.

Calculation of materials

It is easiest to make a hanging swing with a metal support and a wooden swing-balancer.

Materials will need these:

- 2 iron pipes for supporting poles (d = 74 cm);

- 2 bearings;

- 1 metal pipe (for a crossbeam) with a length of 50 cm (d = 150 mm);

- ready-mix mortar for concreting;

- apparatus for welding;

- 2 plates of metal are not already 7 cm.

For a swing-balancer, prepare:

- any wooden material (the average length is 2.5 meters). You can take the usual thin log, bar (thickness 40-50 mm) or a board about 25 cm wide.

- board for seats (width - 30-40 cm, length - 45-60 cm) with a thickness of at least 30 mm.

- metal rod for support.

- hardware.

- paint or primer.

- 2 wooden handles (they can be made from a wooden rod 25 mm in diameter, about 60 cm long).

Schemes of street swings

To facilitate the work on making a swing, you can make a scheme of construction. Drawings are done independently (under individual parameters) or taken ready from different sources.

Photogallery: examples of drawings

The swing design must be very stable

Based on the compiled scheme, it is possible to build frame swings made of wood

The diagram must specify the dimensions of each part

Preparation of the instrument

Depending on which design you preferred, you need to prepare:

- welding machine;

- drill;

- a hammer;

- shovel or hand drill;

- screwdriver;

- the Bulgarian;

- hacksaw;

- roulette;

- plane.

Step-by-step instruction for the manufacture of a hanging swing with a chain and a wooden seat

Having prepared everything you need, you can start working:

Applying a manual drill, you significantly reduce the time of construction of the swing

For this step, you can take a ready-made solution

There is another reliable way to fix the supports and the crossbar - by welding a special design (this option is very suitable for connecting wooden elements of the structure).

Using a special element for connecting parts, you can ensure the reliability of your design

In the central part of the crossbeam, bearings are mounted using metal plates. Bearings must allow the swing to move in the "forward / backward" direction. Further actions are:

Bearings are required in regular lubrication

For safety, you can use a solid metal structure on which a wooden seat is attached

The state of the swing should be carefully monitored. It is necessary to lubricate the bearings regularly with engine oil and tint the peeling details.

Before you invite the kids to ride, try a swing yourself.

Video: how to make a swing from the profile pipe in the country house with your own hands

How to make a swing-balancer for a child from a tree with his own hands

Drawing on the drawings and armed with the necessary materials, a tool, you can start assembling the swing-balancer from the tree. The work is carried out in 4 stages:

- installation of the base;

- the manufacture of rocker-rocker;

- assembly;

- painting products.

The diagram you created gives a clear idea of the sequence of actions

The basis is the basis of the design reliability for children. This element of the swing can be built from a wooden beam (10x15 cm), logs (20 cm), boards (not thinner than 3 cm), fixing them in the intended location of future swings. A lower frame of about 1 m in length is built of wood, and vertical supports or posts at an angle are fastened (using screws) to it.

The rocker-balancer is easiest to make of a bar or a thick board.

The entire length of the balance bar (up to 2.5-3 m) is laid two bars parallel to each other, between them (on both sides) are placed the bars shorter (up to 1 m). The whole resulting structure is fixed with screws or waterproof glue (for carpentry work). You can use one board.

On the edges of the rocker arms are made seats with handles, in the central part - an opening for the profile pipe.

Handles, like all other wooden parts, should be perfectly smooth, so that the child does not get a splinter in his skin.

Assembling the rocker and the base is done with the help of two pipes: a supporting pipe and a piece built into the center of the swing. They are combined, insert the steel rod into the pre-drilled holes on both pipes.

Possessing certain skills, it is possible to build a swing-balancer for children

Video: how to make a product from tires

Decoration process

After the swings are mounted, you need to take care of their appearance. It is easiest to paint with oil paint. This method is suitable for both wooden and metal structures. You can dream up and make a swing especially attractive for the children.

The easiest way to decorate is paint coloring

Do not neglect the rules of using children's swings, which will help to avoid injuries. You can not:

Before using the swing, it is necessary to carefully inspect all components and connections for their integrity and functionality. Regularly lubricate the swing, preventing rust and creaking. Make sure that there are no sharp objects, protruding bolts, unpolished wooden parts in the structure.

Swing with your own hands is easy. The main thing is to adhere to the technology of manufacturing the product and the recommendations of specialists.