Fittings for polypropylene pipes: types and process of installation. The special need for stubs is determined. PP elbow with union nut

Today in specialized stores you can find a wide variety of fittings for polypropylene pipes. When choosing such a modern material for laying polypropylene pipes, you need to know which types of fittings are usually used during the installation.

Basic types of fittings

Fittings are usually divided by diameter and shape. The shape of the fitting determines the angle of the joint. The following fittings are most often used for the installation of polypropylene pipes:

- couplings;

- adapters;

- corners;

- tees;

- expansion joints.

Now consider the purpose of each species in more detail:

- Coupling refers to the simplest kind of fitting. They are shaped like a barrel with a hole in it, and serve to connect pipes of the corresponding diameter.

- Adapters also refer to a simple type of fittings. Unlike couplings, they have different diameters at different ends, which allows connecting pipes of different cross-sections. If the adapter is installed from the propylene glue pipe to the threaded one, it has, on one side, an internal or external thread.

- Angles are used for installation in the places where the pipeline rotates. The corner allows to create the necessary angle of rotation without deformation of the polypropylene tube itself. They come with a bend angle of 45 and 95 degrees, and can also combine pipes of different diameters. Corners can have an external metal thread, which allows you to connect them with mixers in the bathroom or with other plumbing.

- In addition, there are tees that allow the connection of several pipes on the wiring. They can have different diameters and internal relief. You can pick up plastic fittings that fit a variety of pipes, including those that can connect heterogeneous pipes.

Polypropylene fittings: 1-coupling; 2 - adapter; 3 - corner; 4 - T-piece

In the event that it is required to draw a pipeline around an object, it is possible to use contours that avoid the inflection of plastic pipes.

Features of installation of polypropylene pipes

Installation of additional equipment

When installing polypropylene pipes, it is necessary to take into account the factor of temperature expansion. This is important on heating systems and on water pipes with hot water. For this, it is necessary to install expansion joints on propylene pipes.

The main functions of the expansion joints are:

- Absorption of temperature changes and strong pressure spikes in the heating and water supply system.

- Preserving the integrity of the entire system.

- Increase the reliability of the plastic pipeline.

It is also possible to distinguish the expansion joints by the material from which they are made.

You can use metal expansion joints, they can be:

- compensators axial bellows CSR;

- bellows expansion joints;

- shear Compensators (CCC);

- rotary compensators (PCB);

- compensators universal (КСУ).

Universal expansion joints are usually installed on small structures.

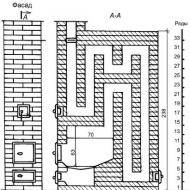

There are devices with a flexible connection made of elastic materials. The most common are P- and L-shaped structures, as well as loop-shaped compensators and "snakes".

Threaded connection with metal pipes (American)

The connection of plastic pipes by means of the threaded method does not provide great strength of the connection. In this case, sealing of the elements of such a design gives greater sealing. If you can not get rid of a threaded connection for some reason, American women will be fine for polypropylene pipes.

This is a special detachable combined fitting that has a metal thread on one side and a polypropylene base on the other. On the one hand, it will be screwed to the metal, and on the other hand it will be welded to the plastic.

Choosing the right diameter for fittings

Most often used fittings for plastic pipelines, whose diameter is 20,25,30 and 40 mm. In general, fittings with a diameter of up to 110 mm can be found on the market. But such a large diameter is usually used when laying pipelines for industrial use. For a private house or a city apartment, pipes and fittings with a diameter of 20 mm are best suited.

When choosing fittings, you must pay attention to the dimensions of the diameter. They should be suitable for the diameter of water pipes. For correct selection it is necessary to specify the pipe diameter. Usually the diameter is indicated on the product label.

Correctly picking up the components for polypropylene pipes, you can conduct installation of polypropylene pipes on your own. The most common use of polypropylene pipes type PPRC, so pick up fittings for PP pipes is quite simple. It is necessary to follow the manufacturer's recommendations clearly and carefully read the product label.

Welding of polypropylene pipe with fittings

Main stages:

- preparation of the necessary tool.

- drawing up a pipeline plan.

- cutting pipes.

- welding of pipes and fittings.

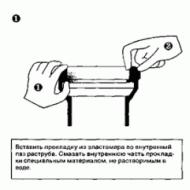

Fittings and fittings are usually attached to plastic pipes by welding. To do this, you will need a special soldering iron with several nozzles that fit the pipe diameters and fittings in size. Before welding, it is necessary to clean it into the inlet area of the fitting. For this purpose, aluminum foil is removed if a pipe with an aluminum layer is used.

![]()

Then the shaped parts for polypropylene pipes and the pipe itself are heated evenly with a soldering iron with a suitable packing and connected to each other.

When gluing pipe parts and fittings, you must avoid rotating the parts. The spike of the elements must be securely fixed at the time of their cooling. Otherwise, the connection will not be sealed and will leak during operation.

When combined with a metal pipe, a different connection method, including both welding and threaded connection, is required. Usually such a combined connection is required when connecting plumbing equipment.

First of all, before starting work, turn off the risers and drain the water in the system. After that, the old water pipe is dismantled.

To speed up the dismantling of the old water pipe, you can simply use the Bulgarian - cut old metal pipes into pieces.

The soldering process is shown in the video below.

After the dismantling works are completed, it is necessary to remove the old valves, to clean the part of the water supply line running up to the riser and proceed with the installation of the new valve. This will help to avoid the congestion in the water supply in this old section of the aqueduct.

Before installation, it is necessary to put the filter on the mixer. This will extend the life of the washing machine, which can be connected to the water supply system in this place.

After all this, you can install a combined fitting. The metal part with a thread is attached to the mixer, and the plastic part is welded to the pipes.

In this section of the site Polypropylene fittings Pro Aqua are presented. Brand products are well known to specialized professionals and ordinary users. It is used to create systems of hot and cold water supply that meet modern needs and standards. We can buy these products quickly and inexpensively with delivery to the right address.

Design

Fittings made of polypropylene "Type-3" are resistant to various external influences. They maintain the integrity of the structure and shape in a wide temperature range, not damaged by heavy loads. Such advantageous characteristics are largely explained by the parameters of the feedstock, the qualitative polymer compound Polypropylene Random Co-polymer.

To strengthen the transitions and threaded connections in cranes and some other products, special metal parts (nodes) are installed. They are made of brass alloy CW617N, therefore are not subject to destructive corrosion process. In particular, these embedded elements with standard output parts simplify the assembly of the engineering system.

Assortment and features of the use of polypropylene fittings

The catalog "Ego Engineering" presents hundreds of products of this category. We can at reasonable prices purchase bends and tees, fittings and flanges, check valves and angled polypropylene connections, valves for radiators.

These and other details are used to create new and improve the consumer characteristics of old engineering systems. To create connections, use special soldering equipment. This technique provides an ideal tightness, high strength. In this diverse assortment, it is not difficult to find products that exactly match a specific technical specification.

Advantages of polypropylene fittings and additional recommendations

The following facts should be considered when studying Pro Aqua products:

- The use of this polymer has helped to increase resistance to mechanical influences of different nature. The products remain intact after strong impacts. They are not damaged by contaminated liquids.

- They are chemically neutral with respect to aggressive compounds, alkalis, acids. Unlike steel analogs, in this case, no special protection against corrosion is needed.

- Sufficiently thick walls of polymer parts absorb sound vibrations, vibrations. This increases the comfort level during operation.

- This material does not change the composition of the liquid flow. According to its environmental characteristics, it meets the strictest international standards.

Polypropylene fittings are used when connecting a water supply system. With their help, a transition is made between pipes of different diameters, the docking of heating components. A special thread of the inner part of each product makes it possible to install with different equipment.

Technical features of polypropylene fittings

According to the structural features and purpose, polypropylene fittings are divided into several varieties. Couplings allow connecting separate parts of pipelines. Angles allow you to change the direction of the pipes by 90 degrees. Plugs and special plugs cover the pipeline, and crosses create branching. Fittings are made of a durable material that allows them to be used for heating, water supply, sewerage.

Polypropylene fittings are characterized by simple installation, high strength, reliability, reasonable price. The structure withstands considerable pressure in the organization of the heating system and a temperature of 95 degrees. Docking does not require the use of glue and volatile materials. The equipment is protected from corrosion and build-up on the inner surface.

Advantages of buying polypropylene fittings

On our site there is a wide selection of polypropylene fittings in different configurations and structural features. The fittings presented in the catalog are suitable for operation in various fields and will become a good alternative to metal analogues. The material does not pollute the environment and is safe for people. Buy the most attractive for installation in certain conditions fittings made of polypropylene can be on our website.

Qualified specialists will select the optimal configuration of equipment that will last for several decades without the need for replacement and maintenance. Polypropylene fittings are suitable for operation in any climatic conditions, regardless of the load. The best solution for organizing a water supply and heating system at an affordable price will be to buy high quality fittings!

Fittings for polypropylene pipes are widely used for the installation of cold and hot water supply systems, pneumatic drive, drainage and sewerage.

Variety of fittings

Classification of fittings is made by diameter and shape. The shape of the fittings determines the angle of joints. When working with PVC pipes, the following fittings are used:

- coupling;

- angled;

- compensatory;

- tees and adapters.

The finished scheme helps to understand the number of dead ends and the intersection of PVC pipes with obstacles that require a bypass. At the design stages, it is accepted to immediately divide the pipeline main into sections, based on the length of PVC pipes. The diagram will show the zones where direct joints are required. They use the simplest fittings - couplings. And where the pipe cross-section is required, special fittings are used.

When choosing the connecting elements that ensure the ease of installation, reliability of operation and long-term operation of engineering systems, it is necessary to determine the size, complexity of construction and the level of load, which will make it possible to maximally profitable to buy fittings for polypropylene pipes. The price of products depends on the type of connection:

- soldering;

- external thread;

- internal thread.

Most of the fittings are equipped with external and internal threads. To achieve maximum tightness of joints, polypropylene pipes need only be welded. Neither glue, nor thread, nor compression joints will not allow to achieve an ideal quality of connection. What is the difference?

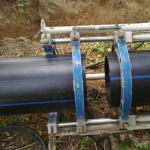

A series of compression fittings for polypropylene pipes affects the change in the geometry of the pipes, reducing the throughput. Pressed connections with gaskets ensure a given level of quality, but with the slightest damage, such joints are not suitable. Welding works deserve more confidence and are produced by means of special soldering irons or welding machines.

The choice of connection technology is represented by 2 options: butt or bell. The first option is less reliable, since in the case of damage or increased pressure, the integrity of the joints is impaired. To connect water pipe elements, fittings with an internal diameter corresponding to the outer section of the pipes used are selected.

PP clutches

Coupling is a small hollow article used to connect two elements of a pipe system of equal cross-section. By external characteristics they look like a barrel. On both sides, pipes are inserted.

Classification of fastenings by purpose allows to divide them into the following types:

- Connecting (installation) are used to exclude the possibility of formation of emergency situations on the pipeline lines, as well as to impart strength and tightness to the pipeline.

- Protective products serve to prevent the formation of defects on PVC structures.

Mounting couplings

The choice of mounting couplings is determined by 2 types:

- Electric, equipped with built-in heating elements for the formation of permanent joints. The purpose of the electric clutch is the possibility of using a welding (welding) method with the self-monitoring of the whole process of welding and cooling joints. Such couplings are usually used in a confined space. The main disadvantages are only the high price of this method.

- Compression and crimping, which do not require special equipment and rapid assembly of detachable connections. Classification of compression fittings allows them to be divided into types: for pipes with an equal cross-section, for joining structures of different sizes, with external and internal threads. Threaded joints serve for joints with pipes made of metal (cranes, valves, adapters, etc.).

Compression clutch design:

- housing;

- an elastic sealing ring providing a hermetic connection;

- clamping ring, preventing the spontaneous unscrewing of the connections during vibrations and water hammers.

- a pressing bushing that holds the seal;

- cover-nut for screed connecting elements.

For tightness of joints, the threads are sealed with special foaming tapes. When tightening the products, there is no risk of damage to the pipes during mechanical impact.

Protective couplings

The use of a protective fitting is actual, if necessary, to make the laying of the pipeline line through the reinforced concrete well. The design of the coupler has the appearance of a solid piece made of PVC (PE 80 or PE 100) to accommodate the pipe. As a result, the lack of contact with the reinforced concrete and the preservation of integrity.

PP Adapters

They are similar to couplings and are used for joining sections of different sections. On the one hand there is a contour of a larger diameter, on the other hand, a smaller one. In this series there are fittings for joining with pipes from metal or heating circuits - they are equipped with metal thread from one side.

Corner joints

Despite the plasticity of the polypropylene, its bends on the outside of the pipes will lead to a rupture with increasing pressure in the system. On the reverse side of the fold, "wrinkles" are formed, which affect the reduction in throughput. Corner areas are used in the areas where reversals are provided. They come in different sizes: 90 о, 45 о. Endings of corners have the same or different cross-section (combined with adapters) or are equipped on the other side with metal thread - for joints of hot water with a mixer, for example.

Corner 90 gr.

Used to change the direction of the pipeline at a right angle. The product is made of PVC and is well used with reinforced and unreinforced pipes. Welding of fittings and pipes is carried out by the bell, products after heating are placed in each other.

Corner 45

Allows you to redirect the track at an angle of 45 grams.

Corner 90 Indoor / Outdoor

Allows you to change the direction of the highway at an angle of 90 degrees. on the sections of joints with shaped parts.

Corner 45 Indoor / Outdoor

Changes the direction of the pipes near the fitting at an angle of 45 g.

Combined square with internal thread

Combined square with external thread

Used to change the direction of the pipeline line with the possibility of connecting PP pipes with steel reinforcing elements or pipes.

Mounting square

The angle bracket with fastening provides the connection of the pipeline with the mixer and automation. It is allowed to fasten the locking reinforcement to the wall surface for stiffening the joint.

Elbow installation elongated

The main purpose of the product is to ensure the angle of rotation of the pipeline, ensuring the connection of the pipeline with steel products or the wall surface, or stiffening the assembly of the assembly.

PP elbow with union nut

Used with split threaded connections.

Tees, crossings

The main purpose of the products is the joint / retraction of several pipe branches. They are characterized by different angles and configurations. In the case of the heating system, welded fittings with a smooth internal threadless surface are well used. Less often, you may need to switch to another type of material, then there is a thread at the ends of the connections.

Transition tee

The use of the fitting is actual in the arrangement of the pipeline main with the transition to a smaller diameter. The working temperature is 95 grams, the pressure is 2.5 MPa, the connection is provided by a butt welding method.

Combined tee with thread from the inside

The product serves for connections with reinforcing elements, mixers, sanitary ware or steel pipes in the pipeline branching areas. Operating temperature 95 g., Pressure 2,5 MPa, butt joint.

Tee with external thread

It is used for joining PVC pipes with reinforcing elements and pipes made of steel with branching of pipes.

Tees with union nuts

The design serves for collapsible threaded joints of PVC pipes with steel fittings or pipes for branching pipes in areas with cold or hot water supply. The maximum heating level is 80 grams, the pressure is 2.0 MPa. The connection is formed by butt welding.

Fences PP

When there is a need to bypass a separate contour, pre-bent elements are used which are welded into the contour in the desired area. The height of the lift and the extent of the fold are different.

Compensator connections

When installing PVC pipes, the temperature expansion and the need for the installation of P- and L-shaped expansion joints, loop compensators and "snakes" are taken into account. This is especially important for heating systems and water pipes with hot water.

Assignment of expansion joints:

- Reducing the level of temperature fluctuations, pressure drops.

- Structural integrity.

- Ensuring reliability.

Types of expansion joints

- Axial bellows series KSO and OPN. Placement of the latest products is easy to install due to the presence of fastening guiding nodes. They are used to immobilize the supports.

- Shift compensator systems KCC are used to reduce the load in two sections relative to the central axis. The product has 1 or 2 corrugated bellows, made of stainless steel and connected by reinforcing elements.

- Reversed PCBs are used to prevent linear expansion in the turns of the pipeline system, allowing you to fix the specified angle when changing the direction of the highway by 90 g.

- Universal KSU series is characterized by the ability to install three types of working stroke - angular, transverse and axial. Typically, such technical elements are used in areas where it is necessary to assemble a small highway or, subject to restrictions, regarding the use of bellows expansion joints.

- Flanged rubber products of the KR type are used in the zones of damping of the shock wave, formed under the influence of a sharp increase in the working pressure from the inside or compensation of inaccurate indexes of the axis of the pipeline system.

There are 2 mounting options:

- With the use of welding.

- Through flanges.

In the first case, the fixation is performed by the method of soldering the ends of the tubes with a bellows compensator having the same cross-section and wall thickness.

Flanged technology allows to fix the compensator not to the pipe, but to the counter flange. This method provides a split joint. In the event of an accident, replacement of the described technical facilities is required. For the assembly of expansion joints, the same corners and pipes can be used or prefabricated hinges can be used. The effect is identical.

Taps and valves

When installing the pipeline, it is allowed to install brass valves or valves placed through the adapter onto the metal, and the cost of such fittings is much higher. The reliability of the unit is not inferior to polypropylene products, and welding of fittings is simpler and faster than threaded joints. As a result, valves and PVC valves are much more convenient and profitable.

Plastic plugs

Typically, when running a water system, complete or partial overlap is required.

The special need for stubs is determined by:

- Overlapping of open parts of pipes.

- Providing vessels for productive activities in conditions of increased pressure.

- Prevention of deformation of pipes or blockages during transportation.

- Protection against sharp edges and edges of pipes.

Clamping technology:

- rotary;

- wafer type;

- welded;

- flanged;

- spherical;

- elliptical.

Blanks for round pipes are used for the water main, rectangular products are necessary for the main pipeline. The products are placed inside and out, but square PVC stubs are placed only on the outside. This allows you to achieve the desired tightness and end protection. But this stub is not particularly strong and can be easily removed.

The internal elements completely enter the pipe, only the decorative element remains in sight. Among the positive qualities is the simplicity of installation and the sturdy characteristics of the case, but the cost of fittings is an order of magnitude more expensive.

Assignment of stubs

The main purpose of the purchase of plugs is to seal the end of the pipeline. These products are used to conceal other elements, for example fastenings on the pipe, it is possible to conceal defects or use in the form of decor.

When working in complex, non-standard conditions, specialized elements are used:

- "Pneumatics" - standard-sized products are not exposed to high-temperature conditions and are installed remotely.

- "Mechanics" - resistant to aggressive environments plastic caps equipped with a padlock.

- Plugs for high pressure pipeline.

Fasteners and fasteners

To fix the pipes to the walls, fixing rings and straps are used.

American PP

The joining of PVC pipes in a threaded manner eliminates the possibility of high connection reliability. The maximum tightness can be achieved through welding products. If there is no possibility to avoid threaded connections, then American women are used - collapsible type of fittings consisting of couplings and union nuts.

They are located in areas where during the period of operation periodic cleaning or removal of system elements (meters for checking, for example) is required. Plug-in combined fittings on one side are equipped with metal thread, and with another PVC base. From one end, the product is screwed to a steel structure, and on the other is welded to plastic.

Diameter of fittings

The diameter of the fittings usually corresponds to the cross-section of the contours indicated on the marking, but to improve the throughput, a number of additional factors should be considered:

Wall thickness

PVC pipes have a significant thickness in comparison with metal or metal-plastic pipes. To determine the throughput, this factor should be taken into account.

Smooth coating

The internal coating of PVC pipes eliminates the presence of roughness inherent in steel, which prevents the formation of obstacles in the form of solid elements (rust or household waste).

Common dimensions

The cross-section of fittings depends on the diameter of the contours that determine the capacity of the water supply line.

Typically, fittings are used for a PVC pipeline with a cross-section of 2; 2.5; 3 and 4 cm. The general assortment of fittings allows you to select products with a section up to 11 cm. However, such large parameters are more often used when laying industrial pipes. In private buildings or urban flats, pipes and fittings with a cross section of 2 cm are well used.

How to determine the dimensions yourself?

When choosing fittings, special attention is paid to the marking of AN and NPT. To translate AN (US military standard) into mm, the following data is substituted: AN * 25,4 / 16. This makes it possible to know the index of the external section of the contour on which the pipe is put. NPT - thread parameters.

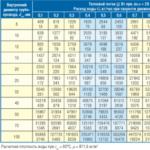

The thread size (mm) has the following characteristics:

Plastic fittings are ideal for wet environments. They have high corrosion resistance, absorb pressure and withstand temperature fluctuations well. Below we can offer a brief overview of prices.

![]()

![]()