Cranes polypropylene

Today, pipeline systems made from polypropylene have found their wide distribution, because they have a lot of positive characteristics. But for their arrangement and operation special fittings are required, which are called About them and will be discussed below.

Description

Polypropylene corner crane also refers to this variety. Its peculiarity is that such products are designed to shut off the water supply. The devices are used in systems of hot and cold water supply, as well as heating. The body of similar products is made of polypropylene, thanks to which the installation of cranes is carried out using the same technology used for connecting polypropylene pipes and other fittings. Their distinctive feature is high throughput and no need for repair and maintenance. It should be noted that such a mechanism should not be used to adjust the intensity of the water flow, since in this case it will quickly fail.

Main characteristics

Polypropylene crane is on sale in a variety of varieties, but below are the characteristics of the crane PPRS PN20. The range of its operating temperature can be in the range from 0 to 95 ° C, while the nominal diameter is 20.63 mm. Quite often consumers are interested in such a question as the period of operation. If it is a tap of the above-described modification, it can be used in cold and hot water supply systems. In the first case, the service life can reach 50 years, but if it is a hot water supply system, the temperature of the working environment should not be more than 75 ° C, while you can expect a service life limited to 25 years. It is important to take into account also the nominal pressure in the system, which should be 20 bar.

For reference

Polypropylene crane has the qualities of chemical resistance, so it found its distribution in conditions not only of domestic pipelines, but also industrial systems, in particular, it is used in pipelines whose internal surfaces are in contact with acids.

Main advantages

Among the advantages of the described products can be identified not only the durability and the absence of the need for maintenance during operation, but also low cost, compact dimensions, as well as good tightness. Any master with the help of improvised tools will be able to install such a mechanism, but in addition it will be necessary to prepare a welding machine. The ease of installation can also be called a weighty advantage. Among other things, the device has an attractive appearance, the internal surfaces do not form scale, and its weight is small. When you choose a polypropylene tap, you should pay attention to the fact that its internal diameter in the gate should correspond to the characteristic peculiar to the pipeline.

Main disadvantages of polypropylene products

If you still have not decided whether to buy a polypropylene tap, you should also learn more about the minuses, but they are not numerous. As mentioned above, this valve can not be used to regulate flow - this feature is sometimes a disadvantage for consumers. Among other things, the device can not be disassembled, so if it fails, replacing it is the main solution to the problem. Disadvantages though exist, but they can not be called critical.

Mounting Features

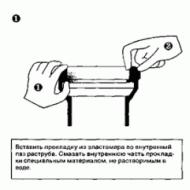

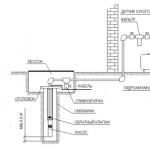

Cranes for polypropylene pipes are installed by a certain technology, which provides for compliance with several stages. The first is the determination of the location of the product. To the tap, you must provide normal access so that the handle can be rotated freely. The next step is to choose a model. The main thing is that the thread is the same, otherwise it will need to be re-cut. When installing polypropylene cocks for heating, it is important to pay attention to the arrows, which are located on the outer surface of the crane. They are necessary for indicating the direction of the flow of water.

The next step will be winding the thread with a ribbon, which will improve the quality of the seal. After that, the crane can be screwed. The master should check to see if there is anything to stop when turning the knob. The crane is screwed with a certain force, if not, then an additional layer of sealant should be wound. Screwing the crane should be accompanied by some effort, while the tape itself will be squeezed out at the joints.

Methods of work

If there is an open thread at the second end of the tap, then it should be wrapped around the tape and screwed on the flange from the tap to the pipe - this will achieve the maximum connection density. Next, you need to check the tightness, for which the system starts up water. If there is no moisture in the junctions, everything is in order, you can start full-fledged operation. Do not use with gas keys, you need to prepare only sanitary.

Connection with the help of "American"

"American" for polypropylene pipes are threading devices that can be disassembled and can be used more than once. The advantageous use of such products is the rapid installation of even the largest parts in hard-to-reach places, with no additional effort to apply. This also applies to repair work in the process of operation.

There are several options, where "American" for polypropylene pipes are used. Among them:

- presence of internal thread;

- presence of a union nut;

- external thread;

- a combination of the methods mentioned above, in different configurations.

For similar threaded connections, fittings are required where there is a thread. Do it yourself on pipes made of polypropylene is impossible. In this case, the assistants will be a sealant and a Teflon tape. If besides the polypropylene tap you want to use the "American" when connecting the pipes, then at the initial stage you need to prepare the last ones, cut and remove the chamfer, where necessary, and if the material is plastic, you need to calibrate.

The next step is to connect the fitting. It is strengthened by the part that is designed for welding. Then the other side of the connector is fixed and most often it is threaded. The master should tighten the choke to check the quality of the work, and if necessary, correct the malfunction. It is important to make sure that there are no leaks, then it should be tightened. It is necessary to provide density to achieve full tightness. If there is no confidence in the "American" or you want to be reinsured, then you can rewind the fuselage thread on the choke thread.

Cost of polypropylene cranes

Polypropylene cranes, whose price is considered quite democratic, are now widespread and are presented for sale in a wide variety. For the faucet-valve, for example, you have to pay 295 rubles., While it costs 369 rubles. Polypropylene cocks for hot water systems can be purchased for 171 rubles. But the polypropylene crane of 20 mm in diameter costs 243 rubles.

If necessary, you can pick up a corner cock for the radiator with an "American", and if the diameter is 20 mm, then for the item you have to pay 147 rubles. When installing pipeline systems, there is sometimes a need for a collapsible direct ball valve with a union nut. In this case, the product will cost 311 rubles.

To date, widespread pipeline systems, which are created from a reliable and high-quality material - polypropylene. In order to equip them and use them for a long time, we need fittings called cranes polypropylene ball.

Application

They are used in systems of cold and hot water supply and heating. With their functional duties, they are doing fine. And this is due to the positive characteristics that such products possess.

The polypropylene crane has one feature: it has a high throughput capacity, and it does not need to be repaired and maintained. Note that you can not use it as a device that regulates the intensity of the flow of water, otherwise it will break down.

pros

What are the advantages of such a crane? Many, but we will distinguish these:

- durability;

- low cost;

- compactness;

- excellent tightness.

It is not necessary to have any special knowledge to establish such a mechanism. Installation is easy, and this is another advantage of the crane. Also note its attractive appearance, light weight, the inability to form scale inside the product.

Where can I buy?

See the cranes that are presented in our catalog, and make the right choice.

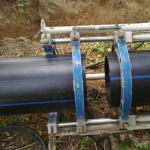

Today pipes made of polypropylene are an integral part of engineering communications. Indeed, because such equipment meets all the requirements, such as ease of installation, flexibility, thanks to which products can be used in the most complex designs, as well as ease of use. When installing such pipes, special PP fittings are required, one of which are polypropylene ball valves. About what these details are and what are their varieties, this will be discussed in today's article.

Characteristics

Such a tap is used to block the flow of water moving along polypropylene pipes. These products are good in that they are made of a light material - polypropylene, so installation takes very little time. The result is a high throughput and complete absence of need for further care.

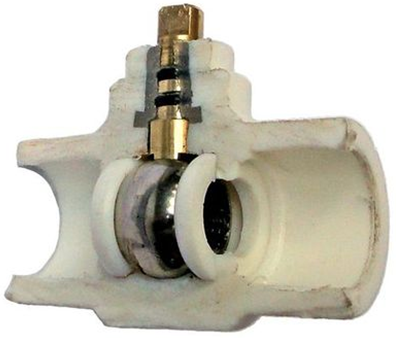

The most important design feature is considered to be movable constipation, made in the form of a ball. When the water is blocked, this ball begins to rotate around its axis (to a word perpendicular to the flow), thereby blocking the passage.

Ball valves vs valves - what is better?

The main argument in favor of the ball valve is the service life. So, if the valves are used for a long time, scale is formed on their surface, so that sooner or later the construction will jam. Moreover, the stuffing box eventually flows, the valves can hardly be considered sealed, and the valve itself is twice as large as the standard ball valve, which complicates installation and further operation. Every year, the valves must be checked carefully.

In contrast, ball valves are devoid of such drawbacks at all - they are light, reliable, look more aesthetic and can last longer (at least half a century). In fairness, we note that ball valves can be not only polypropylene, but also:

- polyethylene;

- steel;

- cast iron.

Note! Most valves begin to flow fluid after fifty cycles, while in the case of ball valves the flow is instantly blocked.

Considering all this, the conclusion suggests itself: ball valves are better than valves in all respects.

Consider all advantages of ball valves made of polypropylene.

- Products have a negligible weight.

- They are very easy to install, which can not be said for metal cranes.

- In the polypropylene construction, impurities and debris do not accumulate, so that the plumbing can be blocked.

- Simple and convenient design, not requiring maintenance. In other words, you just need to put it and use it.

- Durability (more than 50 years).

Features and design features

Each model has its own performance and features. For example, if the product is made of polypropylene PPRC, it can be used in almost any medium at a maximum pressure of 20 MPa and a temperature of not higher than 95 ° C. In addition, spherical polypropylene cranes are manufactured at 20.5, 32, 40 and so on up to 75 MPa.

Polypropylene cranes consist of the following elements:

- the body;

- ball-type butterfly valve with a round through hole for liquid passage;

- rod-seal;

- other seals;

- washers;

- regulating nut;

- handle (faucet).

It is characteristic that the diameter of the hole in the closure should correspond to the internal diameter of the pipeline This avoids the loss of pressure.

Ball valves can be installed on all types of polypropylene pipes - both reinforced and ordinary. It is also worth noting that the ball mechanism itself is made of stainless steel, due to which no corrosion and clogging it is not terrible.

Varieties of ball valves

First of all, such cranes can differ in the quality of the material used in the manufacture. This parameter depends on what type of communication the specific model is intended for. Also, the structures can be designed specifically for cold or hot water.

Depending on the design features, the ball valves are divided into:

- separable;

- collapsible.

Detachable structures are installed in those places where, for one reason or another, the crane can be disconnected. In this case, the connection can be from one or both sides of the product.

AT collapsible cranes The connection is made by means of union nuts. Such a crane can be installed:

- with metal fittings;

- steel pipeline;

- heating radiators.

Demountable models are straight and angular. And if direct all more or less clear, the advantage corner cranes is that they can be used to connect the radiators to the main, without resorting to an American muff. This greatly facilitates not only the installation procedure, but also the further operation of the product, because thanks to the disassembly, you can quickly make repairs if necessary.

Note! There are also special models of cranes, designed to work in an aggressive environment. Their internal surface is made of various materials - chrome-plated brass, "stainless steel" and so on.

The products can be white or gray. In addition, they are applied special color designations, on which you can determine the "specialization" of the water pipe - blue for cold water, red, respectively, for hot water.

Features of purchasing a ball valve made of polypropylene

When buying a ball valve, pay special attention to the quality of the product. It will be great if you take a person who understands this. But if for some reason you plan to do everything yourself, then, first of all, carefully inspect the valve before buying. Make sure that the product there were no cracks and chips, and also that it worked with some effort.

Make purchases in specialized stores. If you are still on the market, then first visit a few pavilions, compare the cost and quality. The fact is that a really good ball valve can not be cheap.

Some more important tips.

- The thread on the product should be the same as on the pipes.

- Never buy used cranes.

- Pay attention to the firm-produces spruce, find out how to build a case with quality control. The fact is that there are many European brands whose products are produced, say, in Russia or Turkey.

- If you do not have the relevant experience, do not try to replace or install the faucet yourself. This is not the case when "learn from mistakes" - the working pressure in the system can reach eight atmospheres.

Note! During operation, the valves must be completely closed or open. There should be no intermediate state.

Mounting the ball polypropylene on the crane with your own hands

First step. Determine the mounting location. It is necessary to ensure normal access to the crane, so that nothing prevents the handle from turning.

Second phase. Then select the appropriate model (as discussed above). The main thing is that the thread is the same, otherwise you have to re-cut it. Also pay attention to the arrows (on the outer surface of the faucets) indicating the direction of the water flow.

The third stage. For better tightness, thread the threads with a special FUM tape and screw the tap. Once again, check to see if anything interferes with the rotation of the handle. The crane should be screwed with some force, if it does not, then wind an additional layer of sealant. As a result, screwing the crane should require effort, and the tape itself will be squeezed out at the junctions.

Fourth stage. If the thread on the second end of the tap is open (that is, the tube will be wound on it), then wrap it with a FUM tape and screw the flange from the tap to the pipe, so you will achieve maximum connection density.

Fifth stage. Check the tightness - let the water out and see if there is moisture in the joints. If everything is in order, you can start a full-fledged operation.

Note! Do not use gas switches - plumbing only.

So we found out what is special about polypropylene ball valves. As we see, it significantly exceeds not only the usual for us valves, but also metal cranes (in particular, steel or brass).

Video - Polypropylene ball valve