Hot-rolled steel pipes, seamless. Seamless hot-deformed steel pipes

Steel pipes of seamless construction are solid pipe metal (without a longitudinal welding joint), obtained by the method of hot deformation using special tube rolling mills. Compared with welded counterparts, they are more durable, reliable and resistant to external influences. Such characteristics make it possible to use them in such technically complex areas as mechanical engineering, chemical, oil industry, etc.

According to the pipe-rolling method, there are two main types:

- cold-deformed seamless pipe (range according to GOST 8734-78);

- seamless hot-deformed pipe (GOST 8732-78 range).

Steel pipes are widely used for the construction of pipelines of water and gas of large and small diameter, the manufacture of structural elements of machines and mechanisms, parts of metal structures, columns, long-span trusses and beams, foundation piles, tubular lighting poles for steel, in road construction, etc.

Seamless pipe according to GOST 8732 is made of steel of various chemical composition using the hot deformation method. Pipes according to GOST 8732 come in various sizes: unmeasured lengths (within 4-12.5 meters), measured in fixed sizes and multiple measured. The weight of the steel pipe in the table according to GOST 8732 depends on the diameter of 20-550 mm and wall thickness from 2 to 45 mm.

The steel pipe gauge regulates the dimensions of the outer diameter, wall thickness according to GOST 8732-78, and technical requirements according to GOST 8731-74. For the manufacture of pipes g / d used steel ingots, blooming and slabs of carbon and alloyed steel according to GOST 1050-88, GOST 4543-71, GOST 19281-89.

Seamless steel pipes are divided into 3 types depending on the ratio of the size of the outer diameter to the wall thickness:

- less than 6 especially thick-walled;

- 6-12,5 - thick-walled;

- 12.5-40 - thin-walled, having a small weight per meter.

Depending on the required quality indicators, seamless hot formed pipes are made of the following groups:

- A - normalized mechanical properties;

- B - standardized chemical composition of steel;

- B - control of the mechanical properties of steel and chemical composition;

- G - with standardization of the chemical composition of steel with the control of mechanical properties on the samples;

- D - without rationing of mechanical properties and chemical composition, but with testing for hydraulic pressure.

Steel pipes are divided into six classes:

1st class (made of carbon steel). The so-called standard and gas pipes, used in cases where there are no special requirements, for example, in the construction of scaffolding, fences, supports for laying cables, irrigation systems. And also for localized distribution and supply of gaseous and liquid substances.

Metal pipes Grade 2 (made of carbon steel) is used in high and high pipelines low pressure for the supply of gas, oil and water, petrochemical products, fuel and solids.

Pipes of the 3rd class are used in systems working under pressure and at high temperatures, in nuclear engineering, in oil cracking pipelines, in furnaces, boilers, etc.

Steel pipes of the 4th class are used for the exploration and exploitation of oil fields, they are used as drilling, casing and auxiliary.

5th class - structural pipes, are used in the manufacture of transport equipment (automobile construction, car building, etc.), (bridge cranes, masts, drilling rigs, supports), as furniture elements, etc.

Steel pipes of the 6th class are used in mechanical engineering for the manufacture of cylinders and pistons of pumps, bearing rings, shafts and other parts of machines, tanks working under pressure. Distinguish pipes of small outer diameter (dimensions up to 114 mm), medium (size of diameter in the range of 114-480 mm) and large diameter (480-2500 mm and more).

Tubes seamless dimensions and weight

The process of making seamless pipes consists of the following technological operations: piercing a hole in a metal blank using a piercing mill consisting of conical rolls and a mandrel piercing, heating the resulting steel billet to 1200 degrees. With and subsequent rolling on a special mill to the desired pipe size.

As a result of the hot-rolled pipe metal production process, the following can be obtained:

Seamless hot-rolled pipes (hot-rolled) according to GOST 8732-78. The dimensions of the outer diameter of the pipes are in the range of 25-700 mm, and the wall thickness varies from 2.5 to 75 mm. Size range: unmeasured length - 4-12 m, measured length is within 9, 12 meters.

Wall thickness is crucial in determining the weight, and hence the cost of the pipe. The practice of specifying prices for the weight of pipe products, rather than linear meters, is associated with the prevalence of metal prices in the cost of the pipe. A piece of course is not weighed. This is a theoretical weight (it is specified in GOST). The theoretical weight of 1 linear meter of steel pipe is calculated by the formula:

Theoretical weight is 1 rm. (kg) = 0.02466 * T * (D - T), where D is the diameter of the pipe in mm, T is the wall thickness in mm.

The calculation of the weight of the pipes (by the size of the diameter and length) and the calculation of the length by the mass and dimensions of the section can be done automatically on the "Metal Calculator", which can be found in the section "Compaction of the Metal Rolling". The pipe calculator will calculate the weight or length of pipe rolled, depending on the input parameters, so that when you buy metal, you are not weighed.

In practice, it looks like this. The seller announces the price of a meter of pipe, the buyer measures the thickness of all selected blanks with a caliper, outside diameter the circumference, the internal diameter of the cavity so that the deviations of dimensions are within acceptable limits, and measures the length of the tube with a tape measure. Batch weight is determined by the theoretical formula by multiplying the theoretical weight per meter by the total length of the car.

If you have any questions related to the selection of the pipe diameter (outer circle or inner hole), wall thickness and length, then you should see the State Standards for steel round pipes (full texts are abundant on the Internet). What kind of GOST standards determine the range of pipes you can download on our website.

| Dimensions and weight of seamless steel pipes according to GOST 8732-78 | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Outside diam |

Weight of 1 m of pipes, kg, with wall thickness, mm | |||||||||||||||||||||

| 3 | 3,2 | 3,5 | 4 | 4,5 | 5 | 5,5 | 6 | 6,5 | 7 | 7,5 | 8 | 8,5 | 9 | 9,5 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | |

| 32 | 2,1 | 2,3 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 33,7 | 2,3 | 2,4 | 2,6 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 38 | 2,6 | 2,7 | 2,9 | 3,35 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 42 | 2,9 | 3,1 | 3,3 | 3,75 | 4,16 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 42,4 | 2,9 | 3,1 | 3,3 | 3,79 | 4,2 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 45 | 3,1 | 3,3 | 3,5 | 4,04 | 4,49 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 48,3 | 3,3 | 3,6 | 3,8 | 4,37 | 4,86 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 50 | 3,5 | 3,7 | 4,0 | 4,54 | 5,05 | 5,55 | 6,04 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 51 | 3,6 | 3,8 | 4,1 | 4,64 | 5,16 | 5,67 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 57 | - | - | 4,6 | 5,23 | 5,83 | 6,41 | 6,99 | 7,55 | 8,1 | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 60 | - | - | 4,8 | 5,52 | 6,16 | 6,78 | 7,39 | 7,99 | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 60,3 | - | - | 4,9 | 5,55 | 6,19 | 6,82 | 7,43 | 8,03 | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 63,5 | - | - | 5,2 | 5,87 | 6,55 | 7,21 | 7,87 | 8,51 | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 70 | - | - | 5,7 | 6,51 | 7,27 | 8,02 | 8,75 | 9,47 | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 73 | - | - | 6 | 6,81 | 7,6 | 8,39 | 9,16 | 9,91 | 10,66 | 11,39 | 12,12 | 12,82 | 13,52 | 14,21 | 14,88 | 15,54 | 16,82 | 18,05 | - | - | - | - |

| 76 | - | - | 6,3 | 7,1 | 7,94 | 8,76 | 9,56 | 10,36 | 11,14 | 11,91 | 12,67 | 13,42 | 14,15 | 14,87 | 15,58 | 16,28 | 17,63 | 18,94 | - | - | - | - |

| 83 | - | - | 6,9 | 7,79 | 8,71 | 9,62 | 10,51 | 11,39 | 12,26 | 13,12 | 13,96 | 14,8 | 15,62 | 16,43 | 17,22 | 18 | 19,53 | 21,01 | 22,44 | 23,82 | 25,16 | 26,44 |

| 89 | - | - | 7,4 | 8,39 | 9,38 | 10,36 | 11,33 | 12,28 | 13,23 | 14,16 | 15,07 | 15,98 | 16,88 | 17,76 | 18,63 | 19,48 | 21,16 | 22,7 | 24,37 | 25,9 | 27,37 | 28,81 |

| 95 | - | - | - | 8,98 | 10,0 | 11,1 | 12,14 | 13,17 | 14,19 | 15,19 | 16,18 | 17,16 | 18,13 | 19,09 | 20,03 | 20,96 | 22,79 | 24,56 | 26,29 | 27,97 | 29,59 | 31,17 |

| 102 | - | - | - | 9,67 | 10,8 | 11,96 | 13,09 | 14,21 | 15,31 | 16,4 | 17,48 | 18,55 | 19,6 | 20,64 | 21,67 | 22,69 | 24,69 | 26,63 | 28,53 | 30,38 | 32,18 | 33,93 |

| 108 | - | - | - | 10,2 | 11,4 | 12,7 | 13,9 | 15,09 | 16,27 | 17,44 | 18,59 | 19,73 | 20,86 | 21,97 | 23,08 | 24,17 | 26,31 | 28,41 | 30,46 | 32,46 | 34,4 | 36,3 |

| 114 | - | - | - | 10,8 | 12,1 | 13,44 | 14,72 | 15,98 | 17,23 | 18,47 | 19,7 | 20,91 | 22,12 | 23,31 | 24,48 | 25,65 | 27,94 | 30,19 | 32,38 | 34,53 | 36,62 | 38,67 |

| 121 | - | - | - | - | - | 14,3 | 15,67 | 17,02 | 18,35 | 19,68 | 20,99 | 22,29 | 23,58 | 24,86 | 26,12 | 27,37 | 29,84 | 32,26 | 34,62 | 36,94 | 39,21 | 41,63 |

| 127 | - | - | - | - | - | 15,04 | 16,48 | 17,9 | 19,32 | 20,72 | 22,1 | 23,48 | 24,84 | 26,19 | 27,53 | 28,85 | 31,47 | 34,03 | 36,55 | 39,01 | 41,43 | 43,8 |

| 133 | - | - | - | - | - | 15,78 | 17,29 | 18,79 | 20,28 | 21,75 | 23,21 | 24,66 | 26,1 | 27,52 | 28,93 | 30,33 | 33,1 | 35,81 | 38,47 | 41,09 | 43,65 | 46,17 |

| 140 | - | - | - | - | - | 16,65 | 18,24 | 19,83 | 21,4 | 22,96 | 24,51 | 26,04 | 27,57 | 29,08 | 30,57 | 32,06 | 35 | 37,88 | 40,72 | 43,5 | 46,24 | 48,93 |

| 152 | - | - | - | - | - | 18,13 | 19,87 | 21,6 | 23,32 | 25,03 | 26,73 | 28,41 | 30,08 | 31,74 | 33,39 | 35,05 | 38,25 | 41,43 | 44,56 | 47,65 | 50,68 | 53,66 |

| 159 | - | - | - | - | - | - | - | 22,64 | 24,45 | 26,24 | 28,02 | 29,79 | 31,55 | 33,29 | 35,03 | 36,75 | 40,15 | 43,5 | 46,81 | 50,06 | 53,27 | 56,43 |

| 168 | - | - | - | - | - | - | - | 23,97 | 25,89 | 27,79 | 29,69 | 31,57 | 33,44 | 35,29 | 37,13 | 38,97 | 42,59 | 46,17 | 49,69 | 53,17 | 56,6 | 59,98 |

| 180 | - | - | - | - | - | - | - | 25,75 | 27,81 | 29,87 | 31,91 | 33,93 | 35,95 | 37,95 | 39,95 | 41,93 | 45,85 | 49,72 | 53,54 | 57,31 | 61,04 | 64,71 |

| 194 | - | - | - | - | - | - | - | 27,82 | 30,06 | 32,28 | 34,5 | 36,7 | 38,89 | 41,06 | 43,23 | 45,38 | 49,64 | 53,86 | 58,03 | 62,15 | 66,22 | 70,24 |

| 203 | - | - | - | - | - | - | - | 29,15 | 31,5 | 33,84 | 36,16 | 38,47 | 40,77 | 43,06 | 45,33 | 47,6 | 52,09 | 56,52 | 60,91 | 65,25 | 69,55 | 73,79 |

| 219 | - | - | - | - | - | - | - | 31,52 | 34,06 | 36,6 | 39,12 | 41,63 | 44,13 | 46,61 | 49,08 | 51,54 | 56,43 | 61,26 | 66,04 | 70,78 | 75,46 | 80,1 |

| 245 | - | - | - | - | - | - | - | - | - | 41,09 | 43,93 | 46,76 | 49,58 | 52,38 | 55,17 | 57,95 | 63,48 | 68,95 | 74,38 | 79,76 | 85,08 | 90,36 |

| 273 | - | - | - | - | - | - | - | - | - | 45,92 | 49,11 | 52,28 | 55,45 | 58,6 | 61,73 | 64,86 | 71,07 | 77,24 | 83,36 | 89,42 | 95,44 | 101,41 |

| 299 | - | - | - | - | - | - | - | - | - | - | - | 57,41 | 60,9 | 64,37 | 67,83 | 71,27 | 78,13 | 84,93 | 91,69 | 98,4 | 105,06 | 111,67 |

| 325 | - | - | - | - | - | - | - | - | - | - | - | 62,54 | 66,35 | 70,14 | 73,92 | 77,68 | 85,18 | 92,63 | 100,03 | 107,38 | 114,68 | 121,93 |

| 351 | - | - | - | - | - | - | - | - | - | - | - | - | - | 75,91 | 80,01 | 84,1 | 92,23 | 100,32 | 108,36 | 116,35 | 124,29 | 132,19 |

| 377 | - | - | - | - | - | - | - | - | - | - | - | - | - | 81,68 | 86,1 | 90,51 | 99,29 | 108,02 | 116,7 | 125,33 | 133,91 | 142,45 |

| 402 | - | - | - | - | - | - | - | - | - | - | - | - | - | 87,23 | 91,96 | 96,67 | 106,07 | 115,42 | 124,71 | 133,96 | 143,16 | 152,31 |

| 406 | - | - | - | - | - | - | - | - | - | - | - | - | - | 88,11 | 92,89 | 97,66 | 107,15 | 116,6 | 126 | 135,34 | 144,64 | 153,89 |

| 426 | - | - | - | - | - | - | - | - | - | - | - | - | - | 92,56 | 97,58 | 102,59 | 112,58 | 122,52 | 132,41 | 142,25 | 152,04 | 161,78 |

| 450 | - | - | - | - | - | - | - | - | - | - | - | - | - | 97,88 | 103,2 | 108,51 | 119,09 | 129,62 | 140,1 | 150,53 | 160,92 | 171,25 |

| 457 | - | - | - | - | - | - | - | - | - | - | - | - | - | 99,43 | 104,8 | 110,24 | 120,99 | 131,69 | 142,35 | 152,94 | 163,51 | 174 |

| 465 | - | - | - | - | - | - | - | - | - | - | - | - | - | 101,2 | 106,7 | 112,72 | 123,16 | 134,06 | 144,91 | 155,71 | 166,46 | - |

| 480 | - | - | - | - | - | - | - | - | - | - | - | - | - | 104,5 | 110,2 | 115,91 | 127,23 | 138,5 | 149,72 | 160,89 | 172,01 | - |

| 500 | - | - | - | - | - | - | - | - | - | - | - | - | - | 108,9 | 114,9 | 120,84 | 132,65 | 144,42 | 156,13 | 167,8 | 179,41 | - |

| 508 | - | - | - | - | - | - | - | - | - | - | - | - | - | 110,7 | 116,7 | 122,81 | 134,82 | 146,77 | 158,69 | 170,55 | 182,36 | 194,12 |

| 530 | - | - | - | - | - | - | - | - | - | - | - | - | - | 115,6 | 121,9 | 128,24 | 140,79 | 153,3 | 165,75 | 178,16 | 190,51 | - |

| 550 | - | - | - | - | - | - | - | - | - | - | - | - | - | 120,0 | 126,6 | 133,17 | 146,22 | 159,22 | 172,16 | 185,06 | 197,91 | - |

So, how to use the table metal? For example, we need to answer the question: how much is the weight of a steel pipe with a diameter of 108 mm? The answer has several options. The fact is that if we are talking about a tabular value of the weight of one linear meter, specified in the assortment of seamless pipes according to GOST, then the mass of 1 linear meter depends not only on the size of the hot-deformed pipe diameter, but also on the wall thickness value. But the wall thickness of the pipe may be different. Therefore, the weight value of 1 meter of running tubes of a certain diameter can vary significantly. This must be taken into account when calculating the weight of pipes, when you want to buy a pipe and in other cases. The value of the weight of the steel pipe 108 mm in diameter, you can find out by extract from the pipe rolled products. According to GOST 10704-63, steel pipe with a diameter of 108 mm can be produced with a wall thickness of 3, 3.2, 3.5, 3.8, 4, 4.5, 5, 5.5 mm. According to GOST 8732-70, steel pipe 108 mm in diameter can be produced with a wall thickness of 4, 5, 6, 7, 8, 9, 10, 12 mm and more. Accordingly, the weight will be different when we talk about the weight of the meter of pipe rolling.

Assortment

Seamless hot-deformed steel pipes. Range of sizes

GOST 8732-78

MKS 23.040.10

OKP 13 1200, 13 1700, 13 1900

Introduction date 01/01/19

1. This standard applies to hot-rolled seamless steel tubesgeneral purpose, manufactured by outer diameter, wall thickness and length.

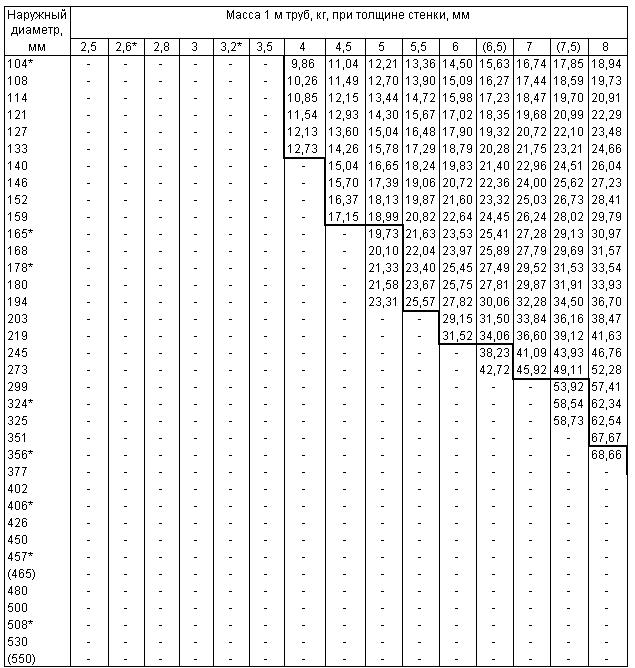

2. Dimensions and weight of 1 m of pipes must comply with those given in table. one

Table 1

Continued table. one

Continued table. one

Continued table. one

Continued table. one

Continued table. one

Continued table. one

N ote:

1. Pipe dimensions, taken in brackets, should not be used in the design of new equipment.

2. The mass of 1 m of pipes is calculated by the formula M = 0.02466 ^ S (D H —S), where D H is the outer diameter, mm;

S - wall thickness, mm.

The density of steel is assumed to be 7.850 g / cm 3.

3. Pipes, the mass of which is limited to a broken fat line, are manufactured by agreement of the manufacturer with the consumer.

4. Pipes with outside diameters and wall thicknesses marked with an asterisk are used in contractual relations for economic, scientific and technical cooperation.

1, 2. (Revised edition, Amendment No. 2).

3. Along the length of the pipe should be made: unmeasured length - ranging from 4 to 12.5 m; dimensional length - within unmeasured;

length, multiple dimensional, - within unmeasured length with an allowance for each cut of 5 mm; approximate length - within unmeasured length.

N ote:

1. By agreement of the manufacturer with the consumer, it is allowed to manufacture pipes of a length exceeding the limits specified for pipes of unmeasured length.

2. For pipes with a wall thickness of more than 16 mm, the length of the measuring pipes is established by agreement of the manufacturer with the consumer.

3. Pipes of approximate length are manufactured at the request of the consumer.

4. Limit deviations along the length of pipes of measured length and length multiple of measured should not exceed: +10 mm - with a length of up to 6 m; +15 mm - with a length of more than 6 m or with an outer diameter of more than 152 mm; ± 500 mm - for approximate length.

3, 4. (Revised edition, Change No. 1).

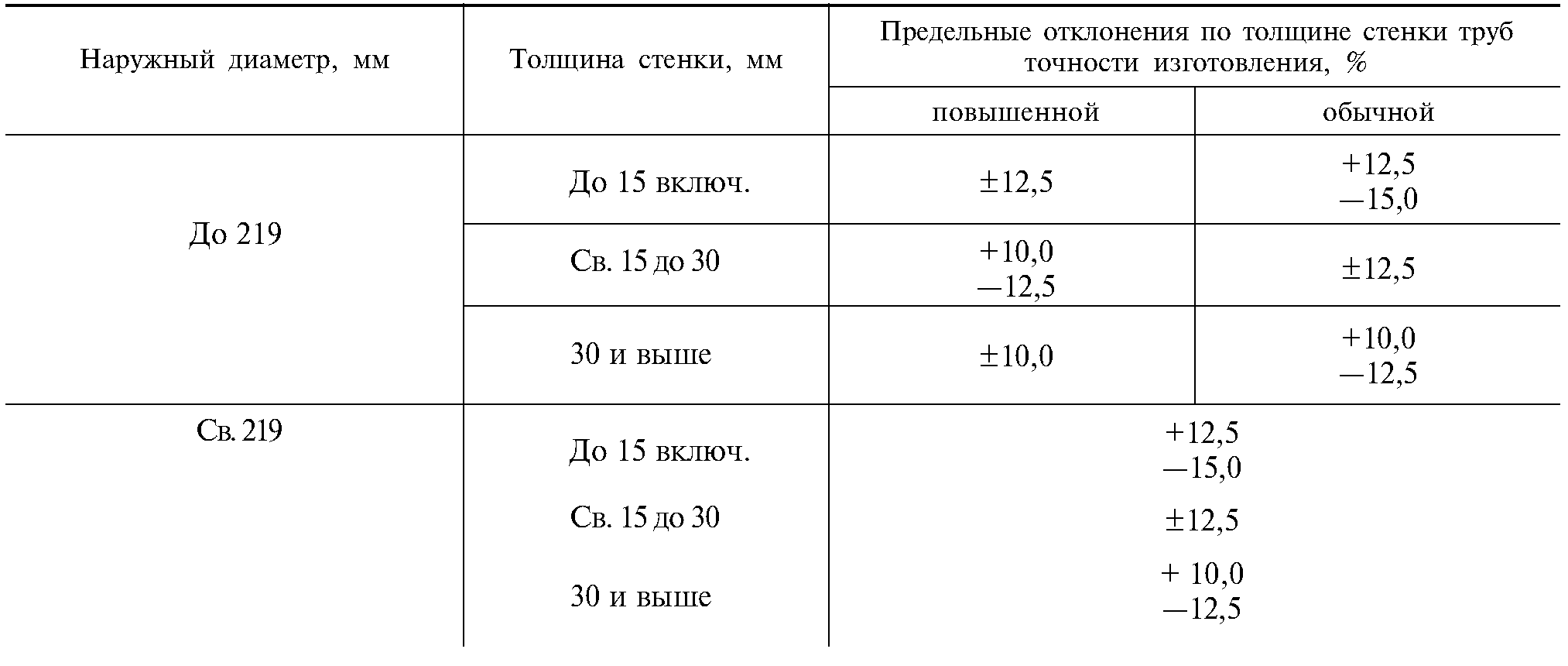

5. Maximum deviations in the outer diameter and wall thickness of the pipes should not exceed those specified in Table. 2 and 3.

Table 2

T a b l and c a 3

6. By agreement of the manufacturer with the consumer, the pipes can be manufactured with combined limit deviations, for example: the outer diameter of increased accuracy according to GOST 9567, and the wall thickness - the usual accuracy, etc.

7. Ovality and delimited pipes should not deduce the size of pipes for the maximum deviations of the diameter and wall thickness.

8. Curvature of any pipe section per 1 m length should not exceed: 1.5 mm - for pipes with a wall thickness of up to 20 mm; 2.0 mm - for pipes with wall thickness from above 20 to 30 mm; 4.0 mm - for pipes with wall thickness over 30 mm.

9. At the request of the consumer, pipes must be supplied in internal diameter and thickness, as well as in external and internal diameters and in thickness.

The maximum deviations in internal diameter for pipes with a diameter of 70–203 mm, a wall of 7–20 mm and a ratio of diameter to wall thickness equal to or less than 10 should not exceed the corresponding maximum deviations in outer diameter, listed in Table. 2

For other pipe sizes, maximum deviations for internal diameter are established by agreement of the manufacturer with the consumer.

PRI me R s u s l o vyh about b about za chen s

The pipe with an outer diameter of 70 mm, a wall thickness of 3.5 mm, a length of a multiple of 1250 mm, and the usual precision of production, from steel grade 10, is manufactured according to group B of GOST 8731:

The pipe with an outer diameter of 70 mm, a wall thickness of 3.5 mm, a length of 6000 mm (length), increased manufacturing accuracy, of steel grade 40X, is manufactured according to group B of GOST 8731:

The same, unmeasured length, is manufactured according to group D GOST 8731:

The pipe with an outer diameter of 219 mm, a wall thickness of 10 mm, unmeasured length, conventional manufacturing accuracy, from steel of the grade St4sp, steel category 1, is manufactured according to group B of GOST 8731

http://metall-energy.ru/data/image/gosty/gost_8732-78_files/gost_8732-78-14.png "style =" width: 234pt; height: 42pt; alt = "(! LANG: alt ="">!}

The pipe with an outer diameter of 95 mm, an inner diameter of 76 mm allowed by a granularity of unmeasured length, the usual precision of manufacture, from steel grade 10, is manufactured in accordance with the BGOST 8731 group:

(Modified edition, Amendment No. 2).

10. Technical requirements - in accordance with GOST 8731.

INFORMATION DATA

1. DEVELOPED AND INTRODUCED BY THE USSR MINISTRY OF METAL INDUSTRY

A. A. Shevchenko, Dr. Tech. sciences; V.P. Sokurenko, Cand. tech. sciences; V.N. Rovensky

2. APPROVED AND INTRODUCED BY Resolution of the State Committee of Standards of the USSR Council of Ministers of 22.03.78 No. 757

3. VZAMEN GOST 8732-70

4. The standard is fully consistent with ST SEV 1481-78

5. REFERENCE STANDARD-TECHNICAL DOCUMENTS

6. The expiration date is lifted under the protocol J№ 3—93 of the Interstate Council for Standardization, Metrology and Certification (ICS 5-6—93)

7. EDITION with Amendments No. 1, 2, approved in February 1982, September 1988 (IUS 5—82, 1—89)

| To buy pipes GOST 8732-78 |

GOST 8732-78

INTERSTATE STANDARD

STEEL STEEL SEAMLESS HOT DEFORMED

Assortment

Seamless hot-deformed steel pipes.

Range of sizes

MKS 23.040.10

OKP 13 1200, 13 1700, 13 1900

Introduction date 1979-01-01

INFORMATION DATA

DEVELOPED AND INTRODUCED by the Ministry of Ferrous Metallurgy of the USSR

DEVELOPERS

A.A. Shevchenko, Dr. Tech. sciences; V.P.Sokurenko, Cand. tech. sciences; V.N. Rovensky

- APPROVED AND INTRODUCED BY A Resolution of the State Committee of Standards of the Council of Ministers of the USSR of 22.03.78 N 757

- VZAMEN GOST 8732-70

- The standard fully complies with ST SEV 1481-78

- REFERENCE REGULATORY TECHNICAL DOCUMENTS

- The expiration date is lifted under the protocol N 3-93 of the Interstate Council for Standardization, Metrology and Certification (ICS 5-6-93)

- EDITION with Amendments N 1, 2, approved in February 1982, September 1988 (ICS 5-82, 1-89)

- This standard applies to hot-deformed seamless steel pipes for general use, manufactured on the outer diameter, wall thickness and length.

- Dimensions and weight of 1 m of pipes must comply with those given in table.1.

Table 1

Continuation of table 1

Continuation of table 1

Continuation of table 1

Continuation of table 1

Notes:

- The dimensions of the pipes, taken in brackets, are not used when designing a new equipment.

- The mass of 1 m of pipes is calculated by the formula

Where - outer diameter, mm;

Wall thickness, mm

The density of steel is assumed to be 7.850 g / cm.

- Pipes whose mass is limited by a broken fat line are manufactured by agreement of the manufacturer with the consumer.

- Pipes with outer diameters and wall thicknesses marked with an asterisk are used in contractual and legal relations on economic, scientific and technical cooperation.

1, 2. (Modified edition, Rev. N 2).

- The length of the pipe should be made:

Not measured length - ranging from 4 to 12,5 m;

Dimensional length - within unmeasured;

Length, multiple dimensional, - within the unmeasured length with an allowance for each cut of 5 mm;

Approximate length - within unmeasured length.

Notes:

- By agreement of the manufacturer with the consumer it is allowed to manufacture pipes of a length that exceeds the limits specified for pipes of non-measured length.

- For pipes with a wall thickness of more than 16 mm, the length of the measuring pipes is established by agreement of the manufacturer with the consumer.

- Pipes of approximate length are manufactured at the request of the consumer.

- Limit deviations along the length of pipes of measured length and length multiple of measure should not exceed: +10 mm - with a length of up to 6 m; +15 mm - with a length of more than 6 m or with an outer diameter of more than 152 mm; ± 500 mm - for approximate length.

3, 4. (Modified edition, Rev. N 1).

- Maximum deviations in the outer diameter and wall thickness of pipes should not exceed those indicated in Tables 2 and 3.

table 2

Table 3

|

Outer diameter, mm |

Wall thickness mm |

Maximum deviations in the wall thickness of the tubes for manufacturing accuracy,% |

|

|

elevated |

|||

|

Up to 15 inclusive |

|||

|

Holy 15 to 30 |

10,0 |

||

|

Up to 15 inclusive |

|||

|

Holy 15 to 30 |

|||

|

10,0 |

|||

- By agreement of the manufacturer with the consumer, the pipes can be manufactured with combined maximum deviations, for example: the outer diameter of increased accuracy according to GOST 9567, and the wall thickness - the usual accuracy, etc.

- Ovality and differential pipe should not display the size of the pipe for the maximum deviations in diameter and wall thickness.

- The curvature of any pipe section per 1 m length should not exceed: 1.5 mm - for pipes with a wall thickness of up to 20 mm; 2.0 mm - for pipes with wall thickness from above 20 to 30 mm; 4.0 mm - for pipes with wall thickness over 30 mm.

- At the request of the consumer, pipes must be supplied in internal diameter and wall thickness, as well as in external and internal diameters and in thickness.

The maximum deviations of the inner diameter for pipes with a diameter of 70-203 mm, a wall of 7-20 mm and a ratio of diameter to wall thickness equal to or less than 10 should not exceed the corresponding limit deviations of the outer diameter specified in Table 2.

For other pipe sizes, maximum deviations for internal diameter are established by agreement of the manufacturer with the consumer.

Legend Examples

The pipe with an outer diameter of 70 mm, a wall thickness of 3.5 mm, a length of a multiple of 1250 mm, and the usual precision of production, from steel grade 10, is manufactured according to group B of GOST 8731:

The pipe with an outer diameter of 70 mm, a wall thickness of 3.5 mm, a length of 6000 mm (length), increased manufacturing accuracy, of steel grade 40X, is manufactured according to group B of GOST 8731:

The same, unmeasured length, is manufactured according to group D GOST 8731:

![]()

The pipe with an outer diameter of 219 mm, a wall thickness of 10 mm, of unmeasured length, conventional manufacturing accuracy, of steel grade St4sp, steel category 1, is manufactured according to GOST 8731 group B of ingot:

![]()

The pipe with an internal diameter of 70 mm, a wall thickness of 3.5 mm, a length of 6000 mm (measured length), conventional manufacturing accuracy, from steel grade 10, is manufactured according to GOST 8731 group B:

A pipe with an outer diameter of 95 mm, an inner diameter of 76 mm allowed by a granularity of unmeasured length, conventional manufacturing accuracy, of steel grade 10, is manufactured according to GOST 8731 group B:

![]()

(Modified Edition, Rev. N 2).

- Technical requirements - in accordance with GOST 8731.

The text of the document is verified by:

official publication

Metal pipes and fittings to them.

Part 1. Seamless smooth pipes: Sat. Gostov. -

M .: IPK Publishing house of standards, 2004

gOST 8732 78, pipe GOST 8732 78, GOST 8732 78 assortment, pipe GOST 8732 78 assortment, pipe GOST 8732 78 assortment, pipe seamless gost 8732 78 assortment, seamless pipe GOST 8732 78 assortment

File Icons and Document Properties - GOST icon;File types

- the document is represented by a set of scanned images; - the document can be downloaded in one PDF file, the file consists of unrecognized scanned pages; - the document can be downloaded in one PDF file with the recognized text; - the document can be downloaded in one PDF file, links to other GOSTs within the file work, the text is recognizedState Statuses

- the document is currently valid (the status of GOST - Acting); - document is canceled (the status of GOST - Canceled); - document is replaced (the status of GOST - Replaced); - GOST is not valid on the territory of the Russian Federation;GOST 8732-78 Seamless hot-deformed steel pipes. Assortment

Categories GOST 8732-78 for ACS:- 23.40. Pipelines and their components

- 23.40.10 Cast iron and steel pipes * steel pipes and tubes for special purposes, see 77.140.75

Document Status: valid, effective 01.01.1979 Title in English: Seamless hot-deformed steel pipes. Range of sizes Type of standard: Standards for products (services) Starting date of the GOST: 1979-01-01 Date of last edition of the document: 2007-03-01

Document codes GOST 8732-78:

OKP code: 131200;131700;131900 KGS code: B62

Number of pages: 11

Purpose GOST 8732-78: This standard applies to hot-rolled seamless steel pipes of general use, manufactured by outer diameter, wall thickness and length.

GRNTI index (s): 534729 The document was developed by the organization: Minchermet USSR Document Keywords: hot rolled seamless steel pipes, product mix, legendYou can download GOST 8732-78 in the following versions:

Date added to file version:

Amendments and changes to GOST 8732-78:

Name, type:

registration:

start of action:

Change No. 1 to GOST 8732-78

Change Type: Text change

Change number: 1

Registration number: 642

Change No. 2 to GOST 8732-78

Change Type: Text change

Change number: 2

Registration number: 3367

New value: -

GOST 8732-78

Group B62

INTERSTATE STANDARD

STEEL STEEL SEAMLESS HOT DEFORMED

Assortment

Seamless hot-deformed steel pipes.

MKS 23.040.10

OKP 13 1200, 13 1700, 13 1900

Introduction date 1979-01-01

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the Ministry of Ferrous Metallurgy of the USSR

DEVELOPERS

A.A. Shevchenko, Dr. Tech. sciences; V.P.Sokurenko, Cand. tech. sciences; V.N. Rovensky

2. APPROVED AND INTRODUCED BY the Resolution of the State Committee of Standards of the Council of Ministers of the USSR of 22.03.78 N 757

3. VZAMEN GOST 8732-70

4. The standard is fully consistent with ST SEV 1481-78

5. REFERENCE STANDARD-TECHNICAL DOCUMENTS

Item number |

|

6. The expiration date is lifted under the protocol N 3-93 of the Interstate Council for Standardization, Metrology and Certification (ICS 5-6-93)

7. EDITION with Amendments N 1, 2, approved in February 1982, September 1988 (ICS 5-82, 1-89)

1. This standard applies to hot-deformed seamless steel pipes of general purpose, manufactured by outer diameter, wall thickness and length.

2. Dimensions and weight of 1 m of pipes must comply with those given in table.1.

Table 1

Continuation of table 1

Continuation of table 1

Continuation of table 1

Continuation of table 1

Notes:

1. Pipe dimensions, taken in brackets, should not be used in the design of new equipment.

2. The mass of 1 m of pipes is calculated by the formula

where - outer diameter, mm;

Wall thickness, mm

The density of steel is assumed to be 7.850 g / cm.

3. Pipes whose weight is limited to a broken fat line, manufactured by agreement of the manufacturer with the consumer.

4. Pipes with outer diameters and wall thickness marked with an asterisk are used in contractual and legal relations on economic, scientific and technical cooperation.

1, 2. (Modified edition, Rev. N 2).

3. Along the length of the pipe should be made:

Not measured length - ranging from 4 to 12,5 m;

Dimensional length - within unmeasured;

Length, multiple dimensional, - within the unmeasured length with an allowance for each cut of 5 mm;

Approximate length - within unmeasured length.

Notes:

1. By agreement of the manufacturer with the consumer, it is allowed to manufacture pipes of a length exceeding the limits specified for pipes of unmeasured length.

2. For pipes with a wall thickness of more than 16 mm, the length of the measuring pipes is established by agreement of the manufacturer with the consumer.

3. Pipes of approximate length are manufactured at the request of the consumer.

4. Limit deviations along the length of pipes of measured length and length multiple of measure should not exceed: +10 mm - with a length of up to 6 m; +15 mm - with a length of more than 6 m or with an outer diameter of more than 152 mm; ± 500 mm - for approximate length.

3, 4. (Modified edition, Rev. N 1).

5. Maximum deviations in the outer diameter and wall thickness of pipes should not exceed those indicated in Tables 2 and 3.

table 2

Outer diameter, mm |

Deviation limits for precision manufacturing pipes |

|

elevated |

||

Up to 50 inclusive |

||

Sv.50 to 219 " |

||

Table 3

Outer diameter, mm |

Wall thickness mm |

Maximum deviations in the wall thickness of the tubes for manufacturing accuracy,% |

|

elevated |

ordinary |

||

Up to 15 inclusive |

12,5 |

||

Holy 15 to 30 |

10,0 |

||

30 and above |

10,0 |

||

Up to 15 inclusive |

|||

Holy 15 to 30 |

|||

30 and above |

|||

6. By agreement of the manufacturer with the consumer, the pipes can be manufactured with combined maximum deviations, for example: in the outer diameter with increased accuracy in, and in wall thickness - in the usual accuracy, etc.

7. Ovality and delimited pipes should not deduce the size of pipes for maximum deviations in diameter and wall thickness.

8. Curvature of any pipe section per 1 m length shall not exceed: 1.5 mm - for pipes with a wall thickness of up to 20 mm; 2.0 mm - for pipes with wall thickness from above 20 to 30 mm; 4.0 mm - for pipes with wall thickness over 30 mm.

9. At the request of the consumer, pipes must be supplied in internal diameter and wall thickness, as well as in external and internal diameters and in thickness.

The maximum deviations of the inner diameter for pipes with a diameter of 70-203 mm, a wall of 7-20 mm and a ratio of diameter to wall thickness equal to or less than 10 should not exceed the corresponding limit deviations of the outer diameter specified in Table 2.

For other pipe sizes, maximum deviations for internal diameter are established by agreement of the manufacturer with the consumer.

Legend Examples

The pipe with an outer diameter of 70 mm, a wall thickness of 3.5 mm, a length of a multiple of 1250 mm, and the usual precision of production, from steel grade 10, is manufactured according to group B:

The pipe with an outer diameter of 70 mm, a wall thickness of 3.5 mm, a length of 6000 mm (measured length), increased manufacturing accuracy, of steel grade 40X, is manufactured according to group B:

The same, of unmeasured length, is manufactured according to group D:

The pipe with an outer diameter of 219 mm, a wall thickness of 10 mm, of unmeasured length, conventional manufacturing accuracy, of steel grade St4sp, steel category 1, is manufactured according to group B from ingot:

The pipe with an internal diameter of 70 mm, a wall thickness of 3.5 mm, a length of 6000 mm (measured length), conventional production accuracy, of steel grade 10, is manufactured according to group B:

A pipe with an outer diameter of 95 mm, an inner diameter of 76 mm allowed by a granular thickness of unmeasured length, the usual precision of manufacture, from steel grade 10, is manufactured according to group B:

(Modified Edition, Rev. N 2).

10. Technical requirements - according to GOST 8731.

The text of the document is verified by:

official publication

Metal pipes and fittings to them.

Part 1. Seamless smooth pipes: Sat. Gostov. -

M .: IPK Publishing house of standards, 2004